Novel fireproof heat preservation plate and production process thereof

A technology of fireproof insulation board and production process, which can be applied in the directions of heat preservation, fire prevention, building components, etc., and can solve problems such as poor fireproof effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

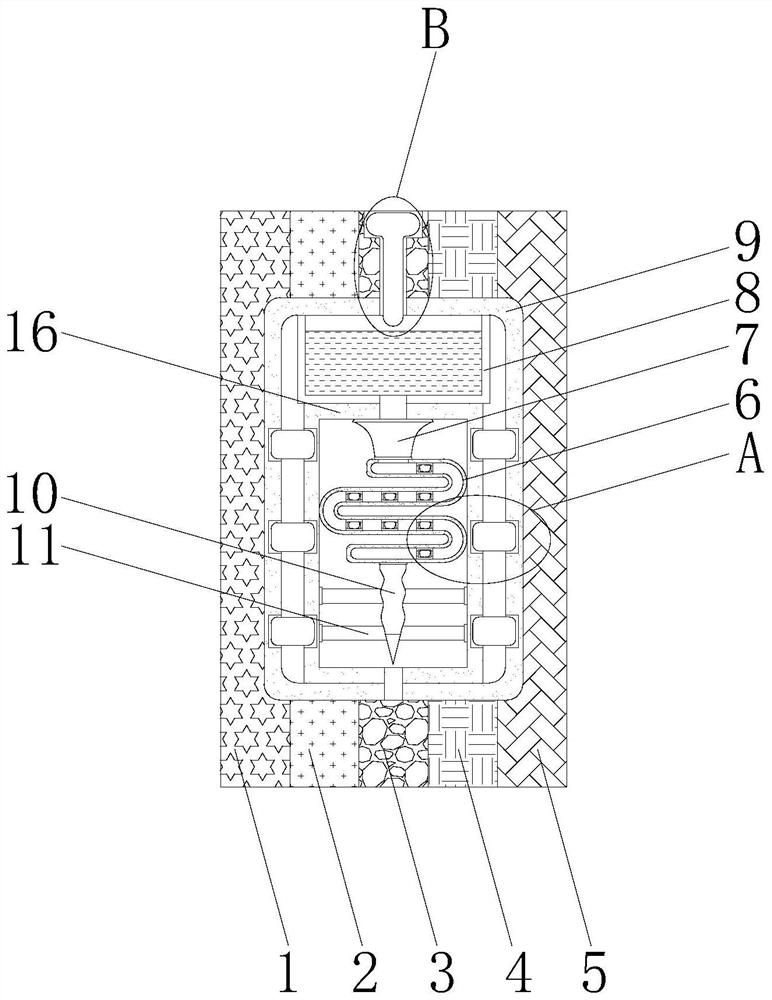

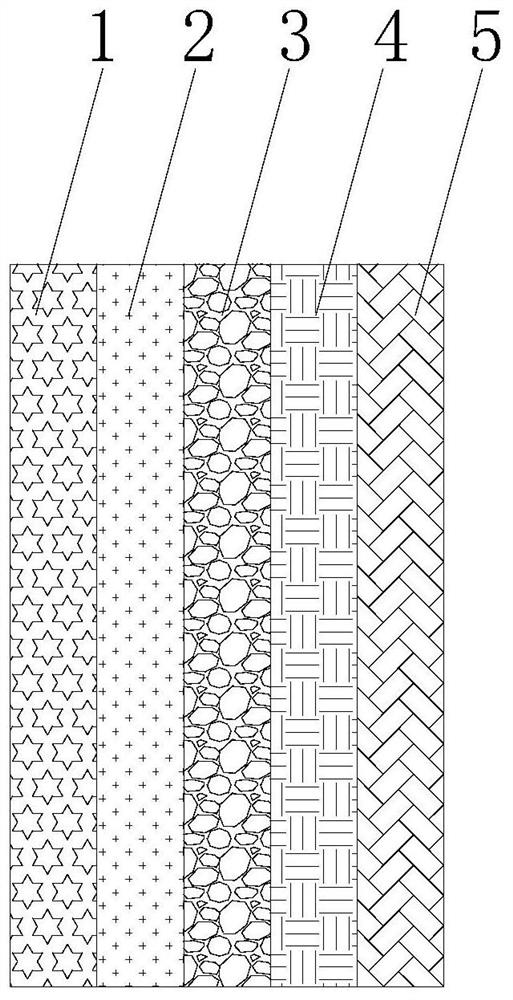

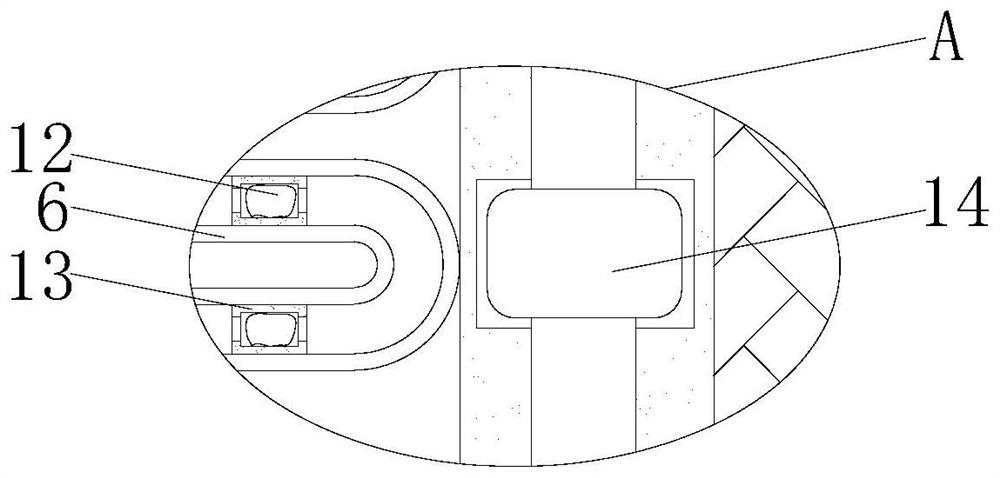

[0028] Such as Figure 1-4 As shown, the present invention provides a technical solution: a new type of fireproof insulation board, including a gypsum board 1, an aluminum-plastic board 2 is fixedly installed on one side of the outer wall of the gypsum board 1, and a silicon Calcium acid fiberboard 3, one side outer wall of calcium silicate fiberboard 3 is fixedly installed with polystyrene foam board 4, one side outer wall of polystyrene foam board 4 is fixedly installed with rigid foam polyurethane 5, gypsum board 1 to rigid foam polyurethane 5 A rectangular hole is opened between them, and the interior of the rectangular hole is provided with a metal storage box 9, the outer wall of the metal storage box 9 is fitted with the inner wall of the rectangular hole, and the inner bottom of the metal storage box 9 is welded with a metal storage box 16. The top of the box 16 is welded with a U-shaped metal shell 8, and the top of the U-shaped metal shell 8 is attached to the inner ...

Embodiment 2

[0038] Such as Figure 1-4As shown, the present invention provides a technical solution: a new type of fireproof insulation board, including a gypsum board 1, an aluminum-plastic board 2 is fixedly installed on one side of the outer wall of the gypsum board 1, and a silicon Calcium acid fiberboard 3, one side outer wall of calcium silicate fiberboard 3 is fixedly installed with polystyrene foam board 4, one side outer wall of polystyrene foam board 4 is fixedly installed with rigid foam polyurethane 5, gypsum board 1 to rigid foam polyurethane 5 A rectangular hole is opened between them, and the interior of the rectangular hole is provided with a metal storage box 9, the outer wall of the metal storage box 9 is fitted with the inner wall of the rectangular hole, and the inner bottom of the metal storage box 9 is welded with a metal storage box 16. The top of the box 16 is welded with a U-shaped metal shell 8, and the top of the U-shaped metal shell 8 is attached to the inner t...

Embodiment 3

[0048] Such as Figure 1-4 As shown, the present invention provides a technical solution: a new type of fireproof insulation board, including a gypsum board 1, an aluminum-plastic board 2 is fixedly installed on one side of the outer wall of the gypsum board 1, and a silicon Calcium acid fiberboard 3, one side outer wall of calcium silicate fiberboard 3 is fixedly installed with polystyrene foam board 4, one side outer wall of polystyrene foam board 4 is fixedly installed with rigid foam polyurethane 5, gypsum board 1 to rigid foam polyurethane 5 A rectangular hole is opened between them, and the interior of the rectangular hole is provided with a metal storage box 9, the outer wall of the metal storage box 9 is fitted with the inner wall of the rectangular hole, and the inner bottom of the metal storage box 9 is welded with a metal storage box 16. The top of the box 16 is welded with a U-shaped metal shell 8, and the top of the U-shaped metal shell 8 is attached to the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com