A remote-controlled manned device for repairing cracks in face-face dams and its operating method

A technology for crack repair and face dam, which is applied in transportation and packaging, underwater operation equipment, sea area engineering, etc. It can solve the problems of limited crack repair work ability, fast physical exertion of divers, unfavorable repair work, etc., to achieve stable and reliable operation The effect of environment, compact structure and long working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

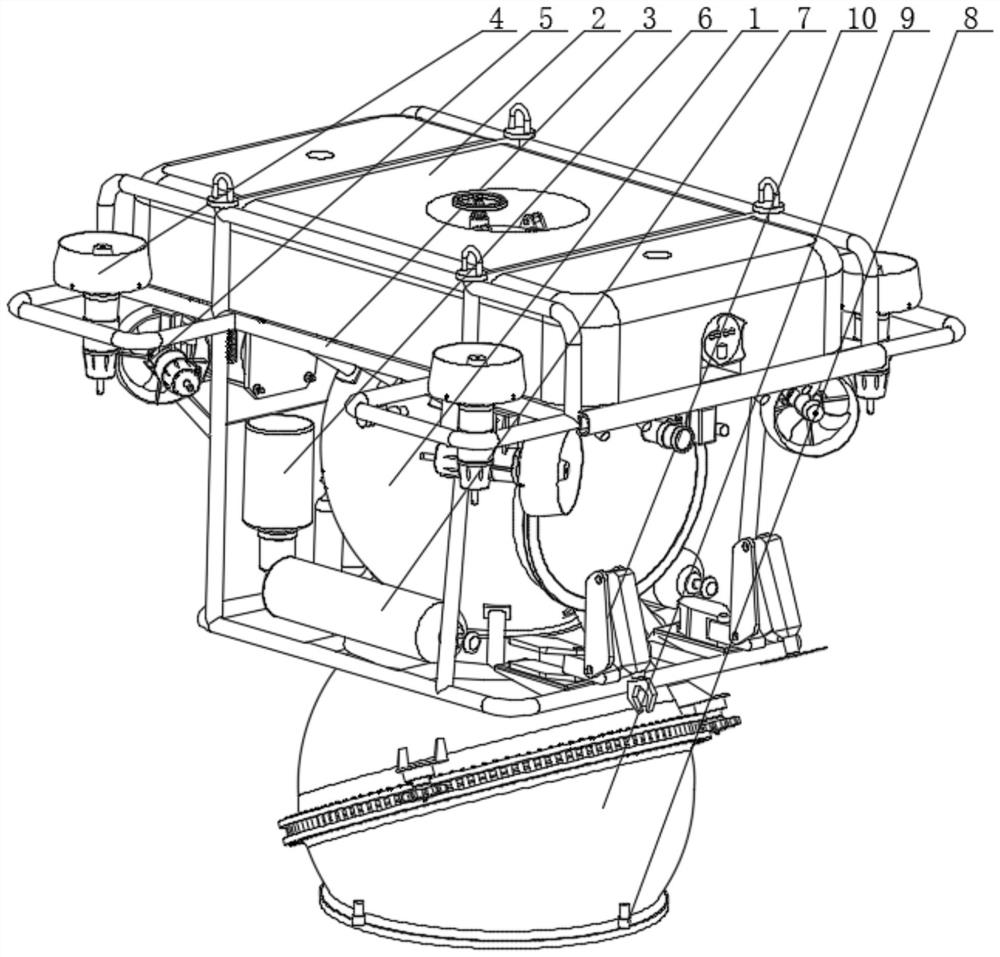

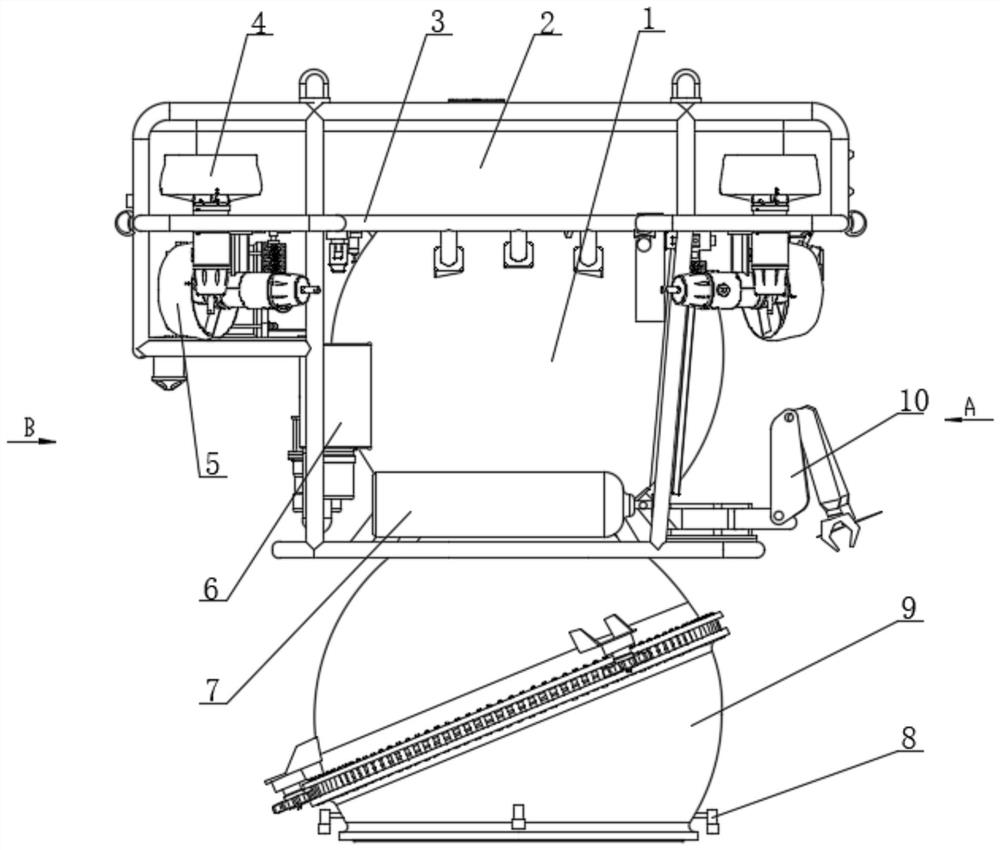

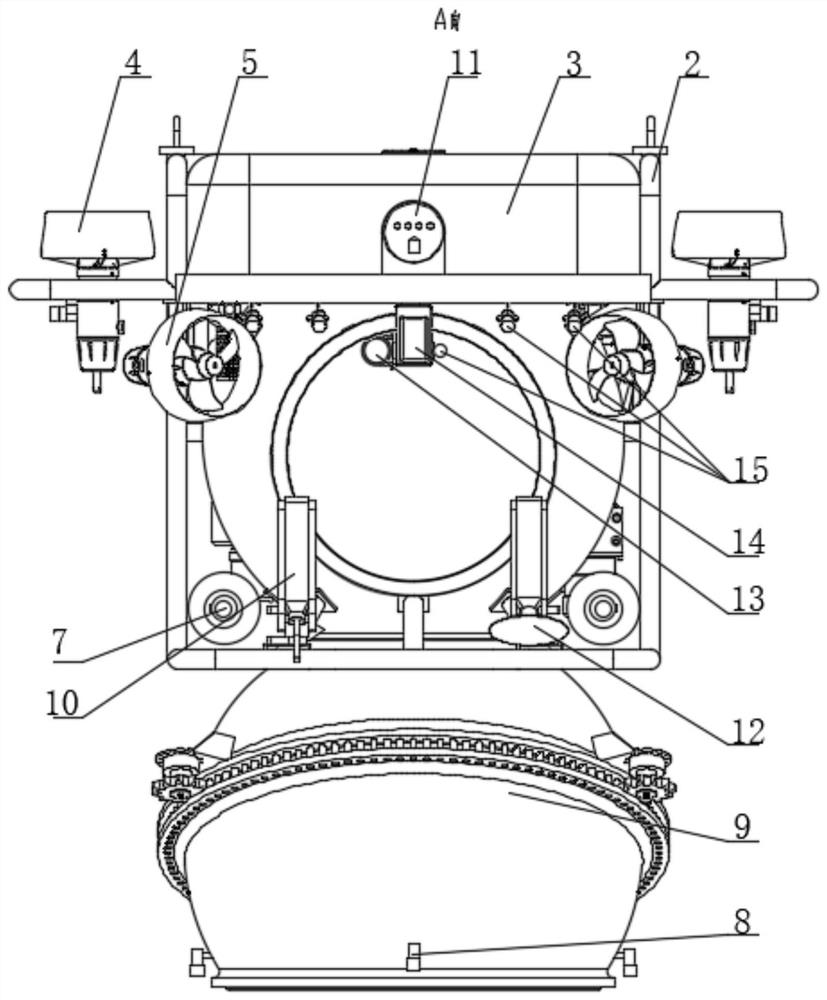

[0053] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0054] Such as Figure 1-Figure 7 As shown, the manned device for repairing cracks in a remote-controlled panel dam in this embodiment includes a carrier frame 3, buoyancy blocks 2 are installed above the carrier frame 3, and vertical thrusters 4 are respectively installed at the four upper corners of the carrier frame 3. and a horizontal thruster 5, the middle part of the carrier frame 3 is welded with a manned cabin 1, and the bottom of the manned cabin 1 is equipped with an adsorption skirt 9 through a sealing device;

[0055] A hydraulic source 6, a seawater pump 17, a high-pressure oxygen cylinder 18, a junction box 16, and a control cabin 19 are installed on the carrier frame 3 outside the manned cabin 1, and a high-pressure air compressor is installed laterally at the front end of the carrier frame 3 outside the manned cabin 1. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com