A kind of gypsum base material imitation wood board and wood square, its preparation method and composite gypsum board

A technology of gypsum base and gypsum board, which is applied in the field of its preparation, composite gypsum board, gypsum base imitation wood plank and wood cube, which can solve the problems of low density and high strength, and achieve low density, high strength and simple preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

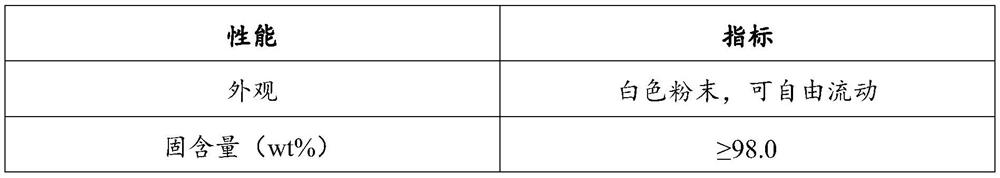

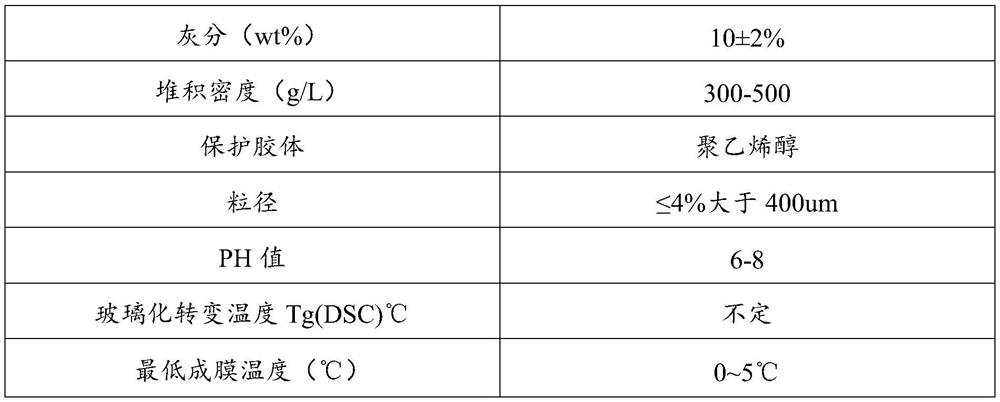

preparation example Construction

[0032] A second aspect of the present invention provides a preparation method of a gypsum-based imitation wood board and a wood square, the steps comprising:

[0033] S1: weigh silica sol, latex powder, chopped glass fiber, wood fiber, dispersant and / or water reducing agent, crystallizing agent, foaming agent and water by proportion, stir and foam at high speed to obtain foaming liquid; During the process, the stirring speed is 1500-2500 r / min, and the stirring time is 2-4 min. By adding silica sol and latex powder in the foaming process, the present invention can fully exert its synergistic effect, support the foam, keep the foam from collapsing for more than 4 hours, and avoid the performance of the gypsum product being reduced due to the premature collapse of the foam.

[0034] S2: Mix the above foaming liquid with gypsum powder, and stir at high speed to obtain a mixture; in this process, the stirring speed is 1500-2500 r / min, and the stirring time is 2-4 min.

[0035] S3...

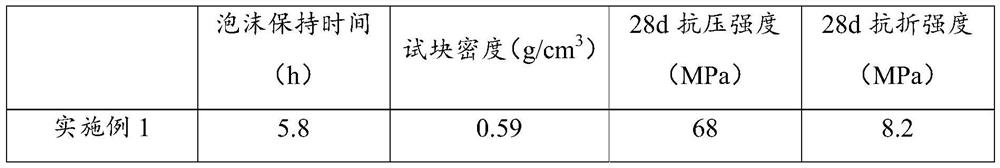

Embodiment 1

[0060] The present embodiment provides a kind of gypsum base material imitation wood board and wooden square, and the specific preparation steps are as follows:

[0061] (1) Weigh 32g of silica sol, 10g of latex powder, 7.5g of chopped glass fiber, 4g of wood fiber H200, 1g of dispersant, 0.5g of water reducing agent, 0.5g of crystallizer, 1.5g of foaming agent and 350g of water. Put it into a stainless steel bowl, and stir at a high speed of 2000r / min for 2 minutes to foam to obtain a foaming liquid;

[0062] (2) slowly pour 500g β gypsum powder into the above-mentioned stainless steel bowl filled with foaming liquid and stir at a high speed of 2000r / min for 2min while pouring to obtain a mixture;

[0063] (3) Pour the above mixture into a mold, vibrate and scrape, and solidify at room temperature for 2 hours to obtain a gypsum substrate imitation wood board and a wood square. Among them, the size of the mold for imitation wood planks is 420mm*300mm*10mm, and the size of the...

Embodiment 2

[0065] The present embodiment provides a kind of gypsum base material imitation wood board and wooden square, and the specific preparation steps are as follows:

[0066] (1) Weigh 50g of silica sol, 30g of latex powder, 15g of chopped glass fiber, 5g of wood fiber H500A, 2g of dispersant, 1.5g of crystallizing agent, 2.5g of foaming agent and 230g of water and pour it into a stainless steel bowl. Stir at a high speed of 2500 r / min for 3 minutes to foam to obtain a foaming liquid;

[0067] (2) 600g α gypsum powder is slowly poured into the above-mentioned stainless steel bowl filled with foaming liquid and stirred at a high speed for 3min at a stirring rate of 2500r / min to obtain a mixture;

[0068] (3) Pour the above mixture into a mold, vibrate and scrape it flat, and solidify at room temperature for 3 hours to obtain a gypsum substrate imitation wood board and a wood square. Among them, the size of the mold for imitation wood planks is 420mm*300mm*10mm, and the size of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com