Metering dust suppression device for grain loading

A technology of metering device and grain, applied in the direction of mass flow measurement device, packaging, loading/unloading, etc., can solve the problems of more or less loading, higher loading cost, low loading efficiency, etc., to reduce the use cost, Good working environment and the effect of improving loading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings.

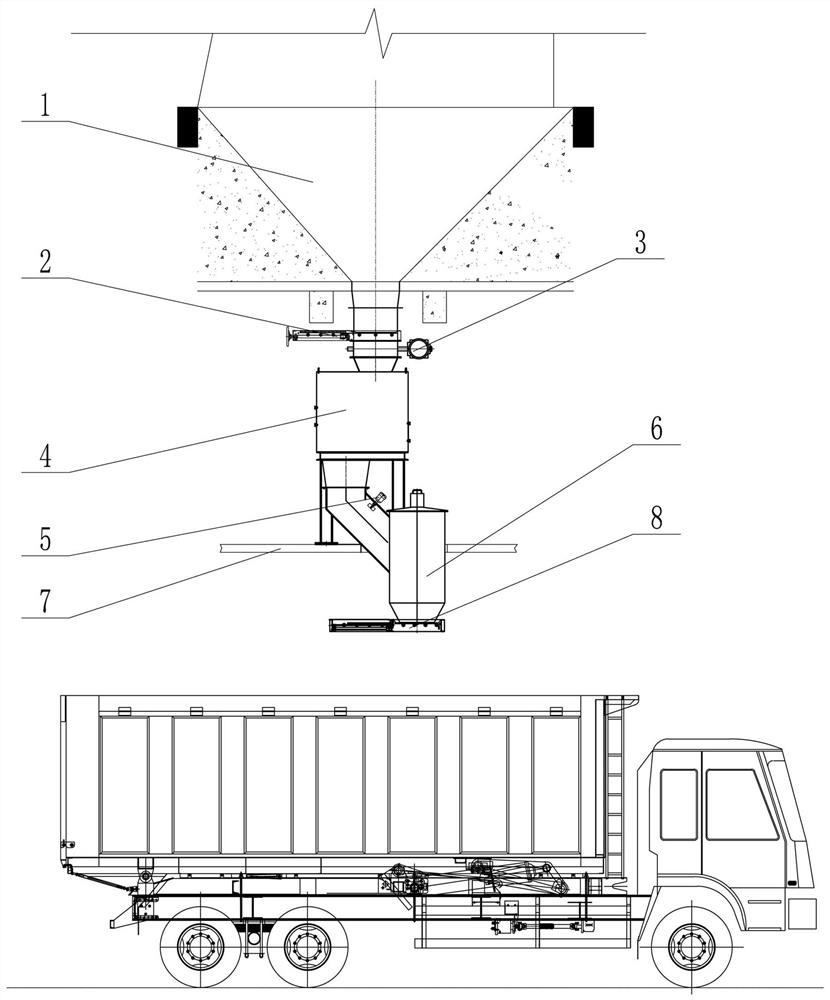

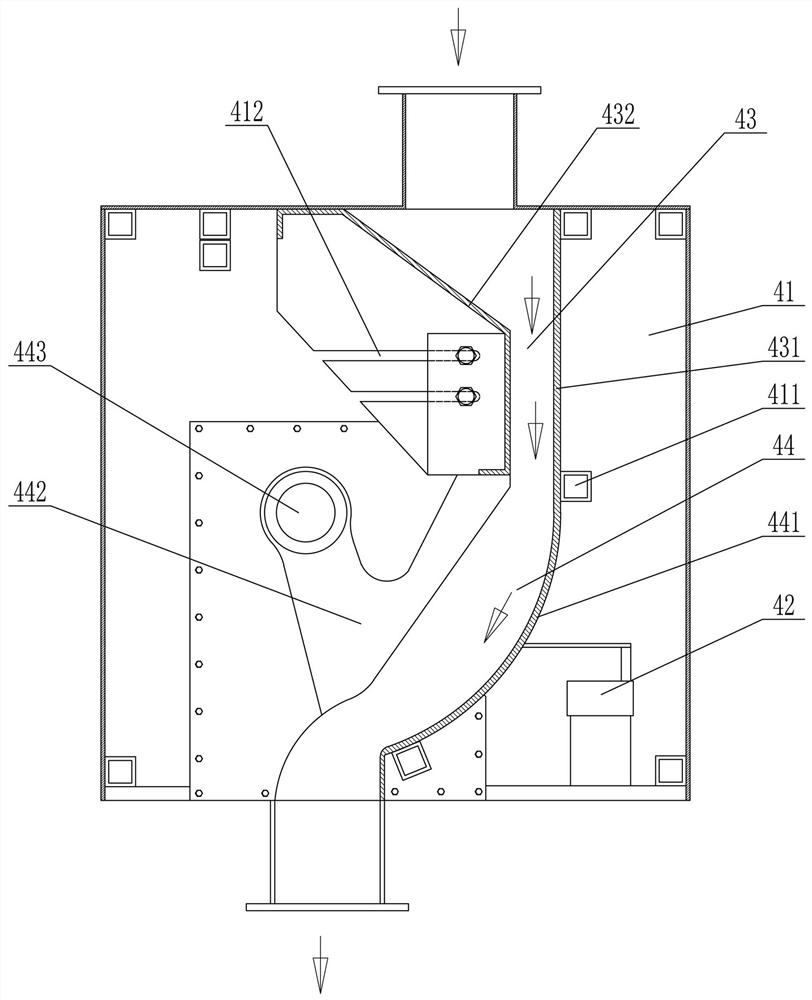

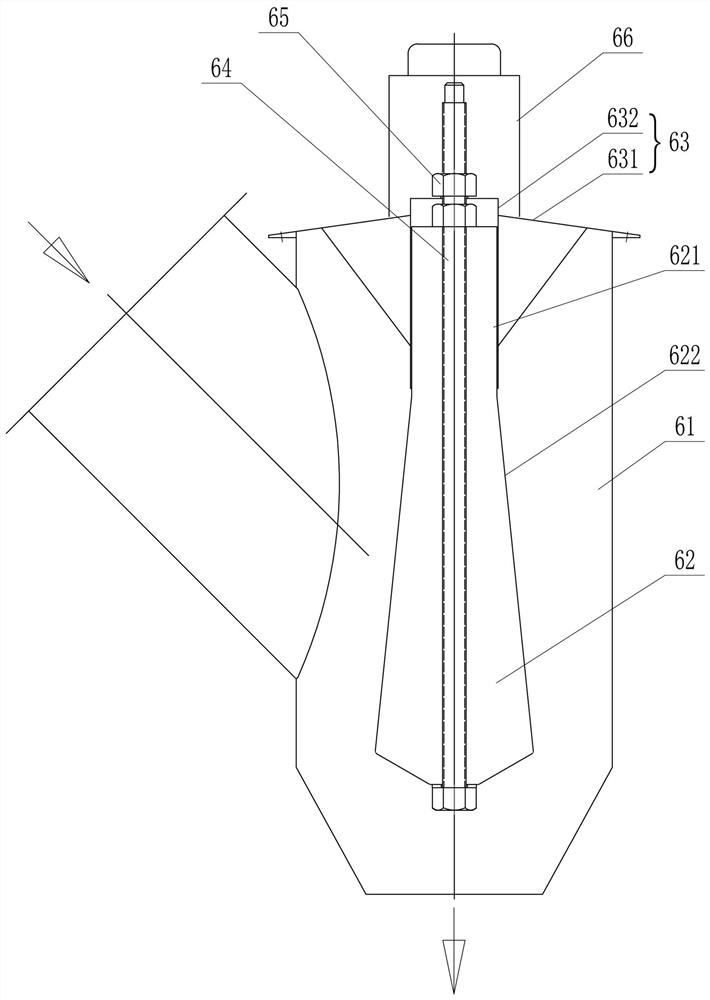

[0028] Such as figure 1 , figure 2 and image 3As shown, a metering dust suppression device for grain loading, a metering dust suppression device for grain loading, comprising a granary 1, a support platform 7, a manual gate 2, a metering device 4 and a dust suppression device 6, the granary The discharge port of 1 is communicated with the feed port of the metering device 4 through a pipeline, the pipeline is provided with a pneumatic flow valve 3, the discharge port of the granary 1 is provided with a manual gate 2, and the pneumatic flow valve 3 is located at Between the manual gate 2 on the discharge port of the granary 1 and the feed port of the metering device 4 . The metering device 4 is a chute scale, and the discharge port of the metering device 4 is connected to the feed port of the dust suppression device 6 through a pipe, and a level gauge 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com