Foam material transferring mechanism

A transfer mechanism and foam technology, applied in the direction of conveyor objects, transportation and packaging, can solve problems such as easy failure, save material waste, save robot investment, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that, as long as there is no conflict, each embodiment and each feature in each embodiment of the present invention can be combined with each other, and the formed technical solutions are all within the protection scope of the present invention.

[0025] The parts not mentioned in the present invention can be realized by adopting or referring to the prior art.

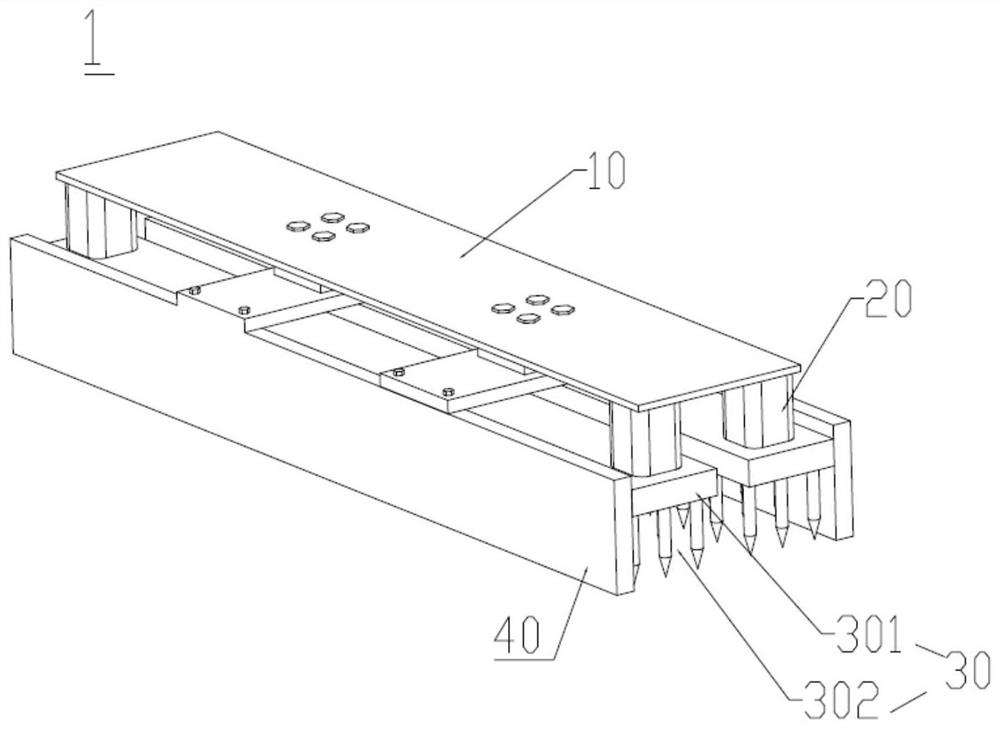

[0026] Such as figure 1 As shown, a foam material transfer mechanism is provided. The foam material transfer mechanism 1 of the present invention includes a base 10, a first driver 20, a second driver (not shown in the figure), a photosensitive element (not shown in the figure) out) and the foam material fetching part 30, the first driving part 20, the second driving part and the foam material fetching part 30 are fixed on the base 10, and the photosensitive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com