Sealed rim propeller or generator

A propeller and sealing wheel technology, which is applied in propulsion engine, propulsion components, ship propulsion, etc., can solve the problems of difficult vibration and noise control, large space occupied by the transmission system, high construction and maintenance costs, and achieve energy conversion efficiency , Strong self-regulation ability, providing the effect of protection level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

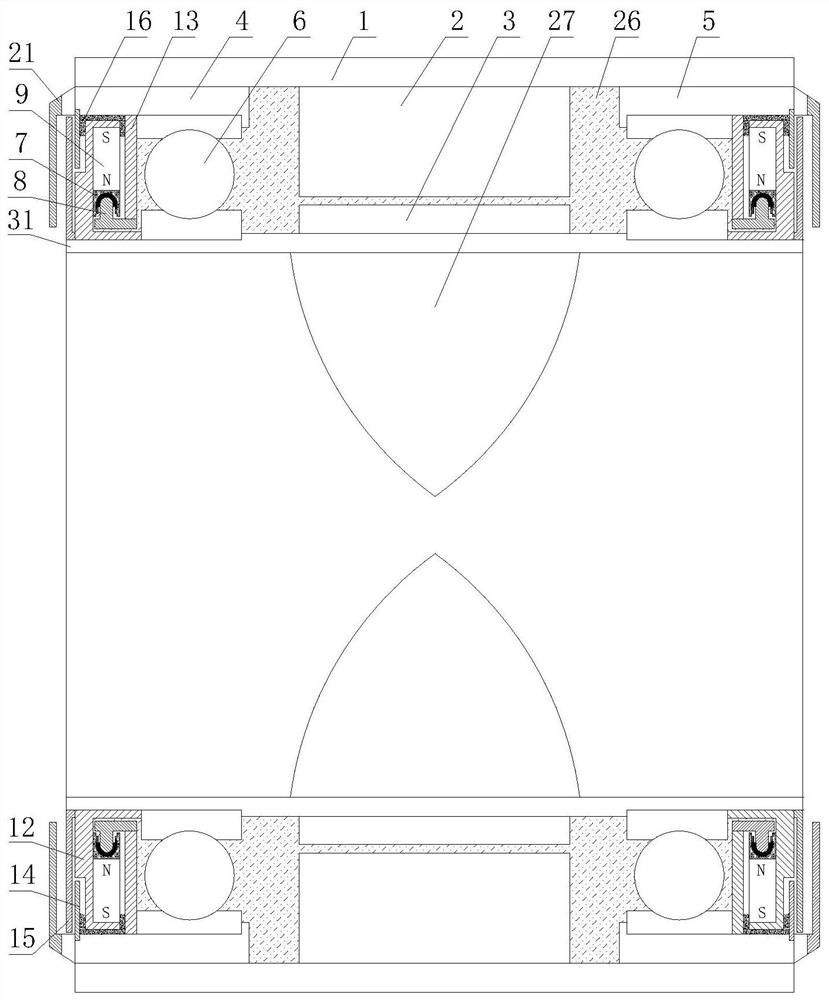

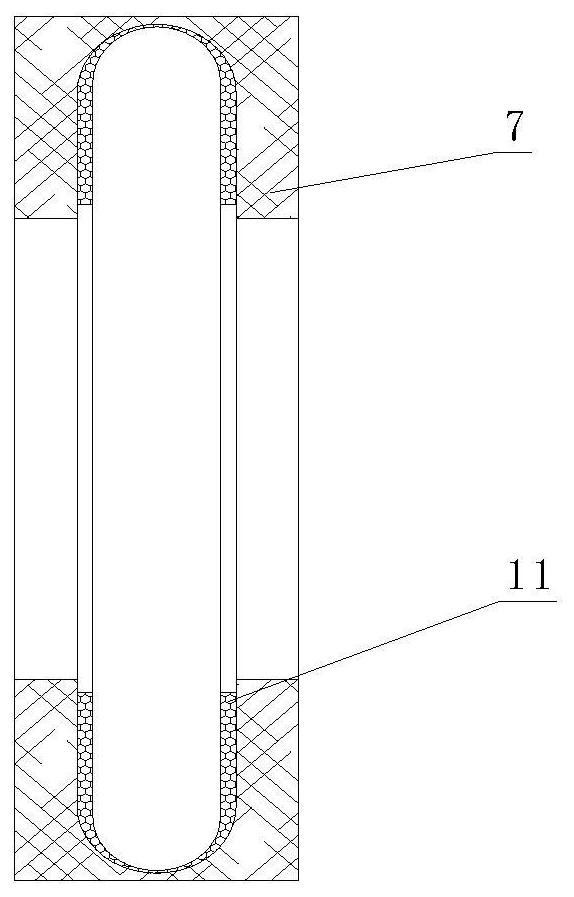

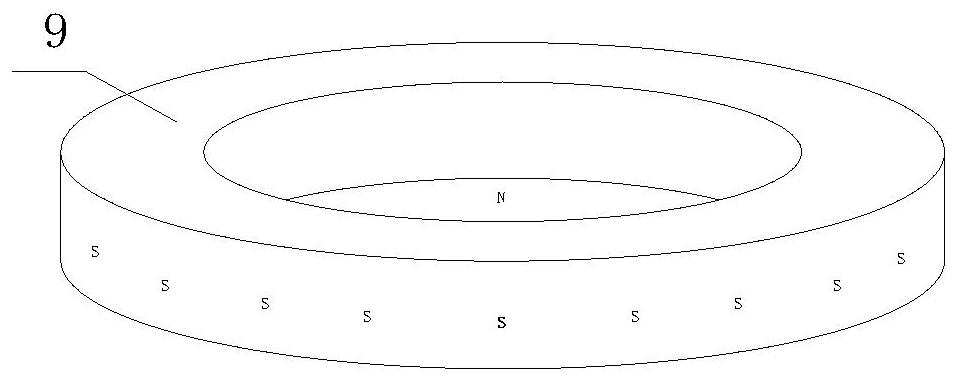

[0037] Such as Figure 1~5 As shown, a sealed rim thruster or generator includes a stator 2, a rotor 3, a housing 1, a front end cover 4 and a rear end cover 5, the rotating shaft 31 in the rotor 3 is a hollow structure, and the shaft 31 passes through the bearing 6 It is fixed coaxially with the stator 2 in the housing 1, and has a built-in paddle 27. The two ends of the housing 1 are provided with the front end cover 4 and the rear end cover 5 supporting the positioning bearing 6; the outer side of the bearing 6 is provided with a sealing assembly , the sealing assembly includes a concave pole 7 and a salient pole 8, the concave pole 7 is connected with the permanent magnet 9 and fixed on the rotating shaft 31 through the rotating ring 12; a shaft sleeve 24 can be added at the end of the rotating shaft 31, and the concave pole 7 The permanent magnet 9 can be fixed on the shaft sleeve 24 through the rotating ring 12, and indirectly fixed on the rotating shaft 31; the concave ...

Embodiment 2

[0041] Such as Figure 6~7 As shown, a sealed rim thruster or generator includes a stator 2, a rotor 3, a housing 1, a front end cover 4 and a rear end cover 5, the rotating shaft 31 in the rotor 3 is a hollow structure, and the shaft 31 passes through the bearing 6 It is fixed coaxially with the stator 2 in the housing 1, and has a built-in paddle 27. The two ends of the housing 1 are provided with the front end cover 4 and the rear end cover 5 supporting the positioning bearing 6. The housing 1 is provided with a The water inlet 25; both sides of the bearing 6 are provided with a sealing assembly, the sealing assembly includes a concave pole 7 and a salient pole 8, and the concave pole 7 is connected with the permanent magnet 9 and fixed in the end cover; A "U"-shaped groove is provided on the concave pole 7, and the concave pole 7 is poured from a flexible material, such as silica gel, polytetrafluoroethylene, etc.; the convex pole 8 is directly fixed on the rotating shaft ...

Embodiment 3

[0044] Such as Figure 8-11As shown, a sealed rim thruster or generator includes a stator 2, a rotor 3, a housing 1, a front end cover 4 and a rear end cover 5, the rotating shaft 31 in the rotor 3 is a hollow structure, and the shaft 31 passes through the bearing 6 It is fixed coaxially with the stator 2 in the housing 1, and has a built-in paddle 27. The two ends of the housing 1 are provided with the front end cover 4 and the rear end cover 5 supporting the positioning bearing 6; the outer side of the bearing 6 is provided with a sealing assembly , the sealing assembly includes a concave pole 7 and a salient pole 8, the concave pole 7 is sequentially connected with the permanent magnet 9 and the exciter 23 from the inside to the outside and fixed in a cage 20, and the cage 20 is fixedly installed on In the installation groove of the end cover; the concave pole 7 is provided with a "U"-shaped groove, and the concave pole 7 is cast from flexible materials, such as silica gel,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com