Anti-skid automobile foot mat production process

A car floor mat and production process technology, applied in the field of anti-slip car floor mat production technology, can solve the problems of reducing the embroidery area of car floor mats, achieve the effects of convenient cutting process, reduction of embroidery area, and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]An exemplary embodiment of the present disclosure will be described in more detail below with reference to the accompanying drawings. Although the exemplary embodiments of the present disclosure are shown in the drawings, it is understood that the present disclosure can be implemented in various forms and should not be restricted herein. Instead, it is provided to provide more thoroughly understood the present disclosure, and can communicate the scope of the disclosure to those skilled in the art. It should be noted that the features in the present invention in the present invention can be combined with each other in the case of an unable conflict. The present invention will be described in detail below with reference to the drawings.

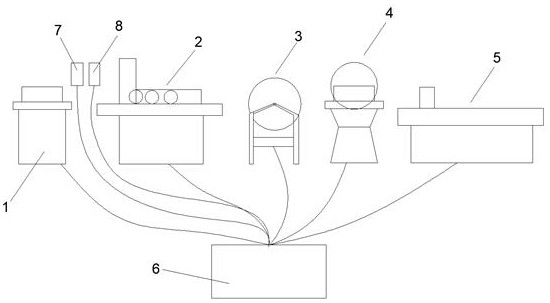

[0044]Seefigure 1 As shown, this embodiment provides a non-slip car foot pad production system, including a hydrophorizer 1, a embroidery machine 2, a roller composite machine 3, a electrostatic circuit 4, and a cutting machine 5, wherein the hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com