Continuous ultrasonic-assisted rubber film calendering device and rubber film preparation method thereof

An ultrasonic-assisted, calendered glue technology, applied to flat products, other household utensils, household utensils, etc., can solve the problems of insufficient dispersion of fillers, insufficient mixing time, and inability to achieve continuous production, so as to prevent non-stick rolls Or can not be plasticized, improve the overall performance, reduce the effect of film bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0037] The present invention will be described in detail below with reference to the accompanying drawings and examples.

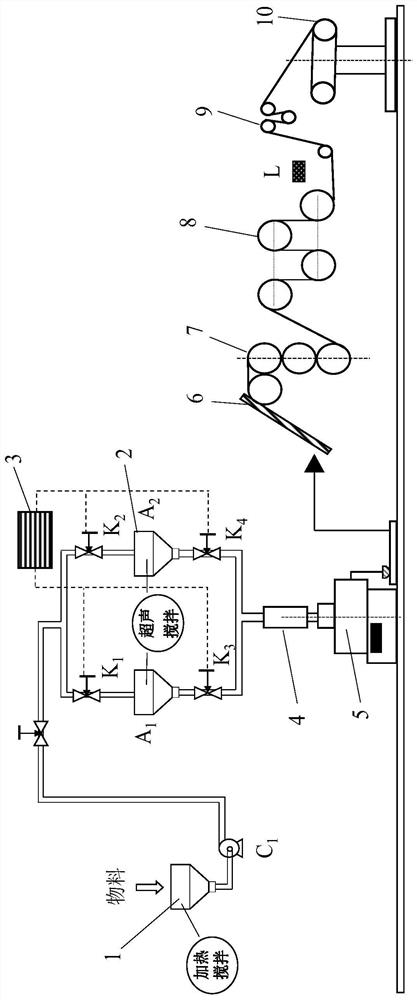

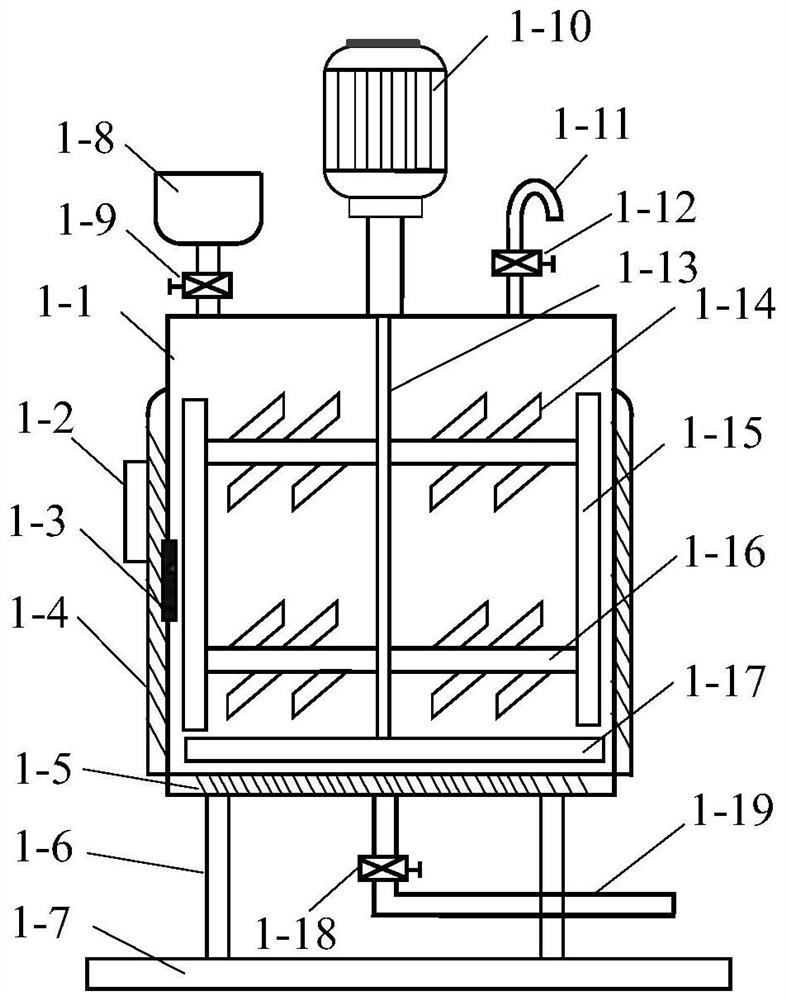

[0038] Such as Figure 1-Figure 5 As shown, a continuous ultrasonic-assisted calendering film device includes an initial mixing mixing tank 1, a fine mixing ultrasonic mixing tank group, an intelligent control system 3, a constant temperature refrigeration device 4, an internal mixer 5, a conveyor belt 6, and a calender 7 , cooling roll 8, tension machine 9 and center coiler 10, described fine mixing ultrasonic stirring tank group comprises two fine mixing ultrasonic stirring tanks 2 that are arranged in parallel, and described initial mixing stirring tank 1 is discharged through primary mixing The pipeline is connected with two fine mixing ultrasonic stirring tanks 2, and a discharge p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com