Polypropylene biaxially oriented film production line

A biaxially stretched film and biaxially stretched technology, applied in metal processing and other directions, can solve the problems of easy looseness of the film, poor edge flatness, and easy wrinkling of the film, so as to improve the appearance quality and uniformity, prevent breakage and The effect of overstretching, ensuring flatness and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

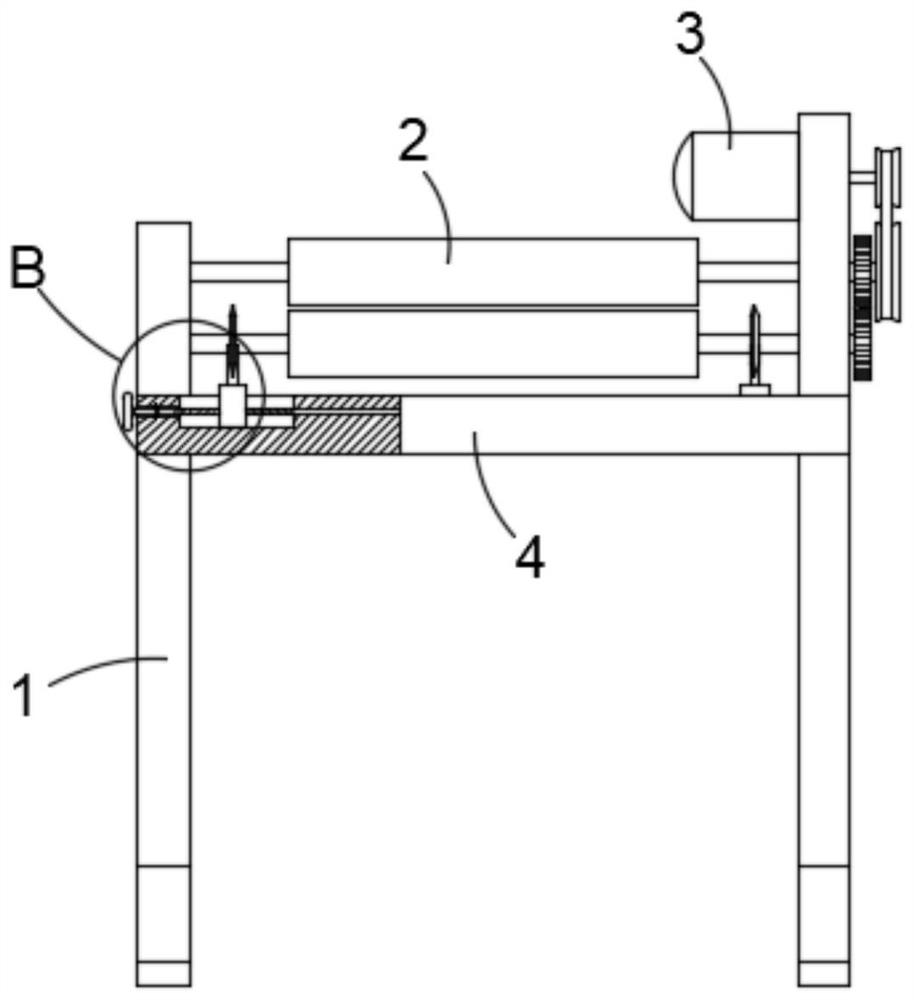

[0035] As an embodiment of the present invention, such as figure 2As shown, the driving mechanism includes a drive motor 3 fixedly installed on one of the mounting frames 1, the ends of the two rubber rollers 2 are equipped with rotating shafts extending to the outside of the mounting frame 1, and circular gears meshing with each other are installed on the two rotating shafts. A pulley is installed on the end of one of the rotating shafts, and a pulley is also installed on the output shaft of the drive motor 3, and the two pulleys are connected by a belt. When the driving motor 3 is working, driven by the belt, the pulley on the rotating shaft rotates, so that the two meshing circular gears rotate in opposite directions, and then the two rubber rollers 2 rotate in opposite directions. When the film passes between the two rubber rollers 2 The friction force exerted by the two rubber rollers 2 on the film tensions the film and feeds the film, and at the same time, the two rubbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com