Method for reducing flatness error of double-sided grinding workpiece

A double-sided grinding and flatness technology is applied to machine tools suitable for grinding workpiece planes, comprehensive factory control, and surface polishing machine tools. It can solve problems such as difficult to ensure high-precision machining, and achieve the reduction of flatness errors. The effect of high-precision machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

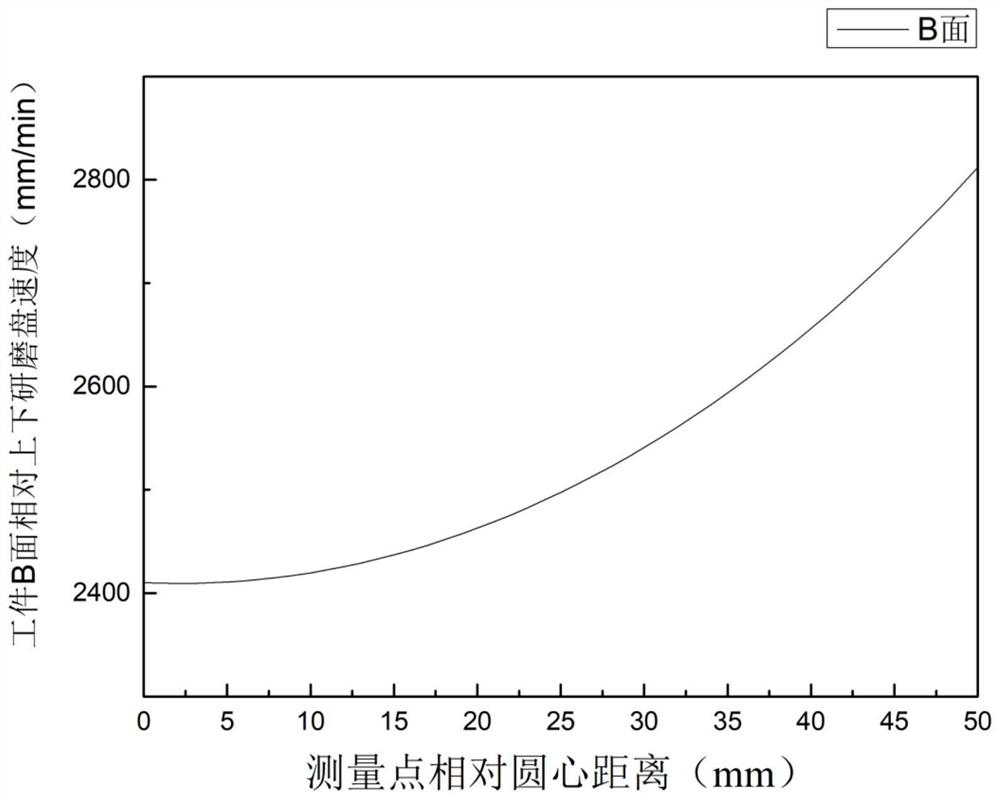

[0024] In order to solve the above problems, the inventor of this case conducted careful design and research, and concluded that the relative speed during the surface grinding process of the workpiece has an impact on the upper and lower shapes.

[0025] Embodiments of the present invention will be described below with reference to the drawings, but the present invention is not limited thereto.

[0026] A method for reducing the flatness error of a double-sided grinding workpiece. Figure 1 is a schematic diagram of the calculation of the double-sided grinding trajectory. When the present invention studies the influence of speed on the upper and lower shapes, the two-sidedness of the workpiece is obtained by calculating the rotational speed of the upper and lower grinding discs and the rotational speed of the workpiece. One surface has a concave surface shape, and the other surface has a convex surface shape. By comparing the relative speed, it is found that the relative speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com