A feeding device for a five-axis linkage vertical machining center

A five-axis linkage and vertical technology, which is applied in metal processing and other directions, can solve the problem of waste of human resources and achieve the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

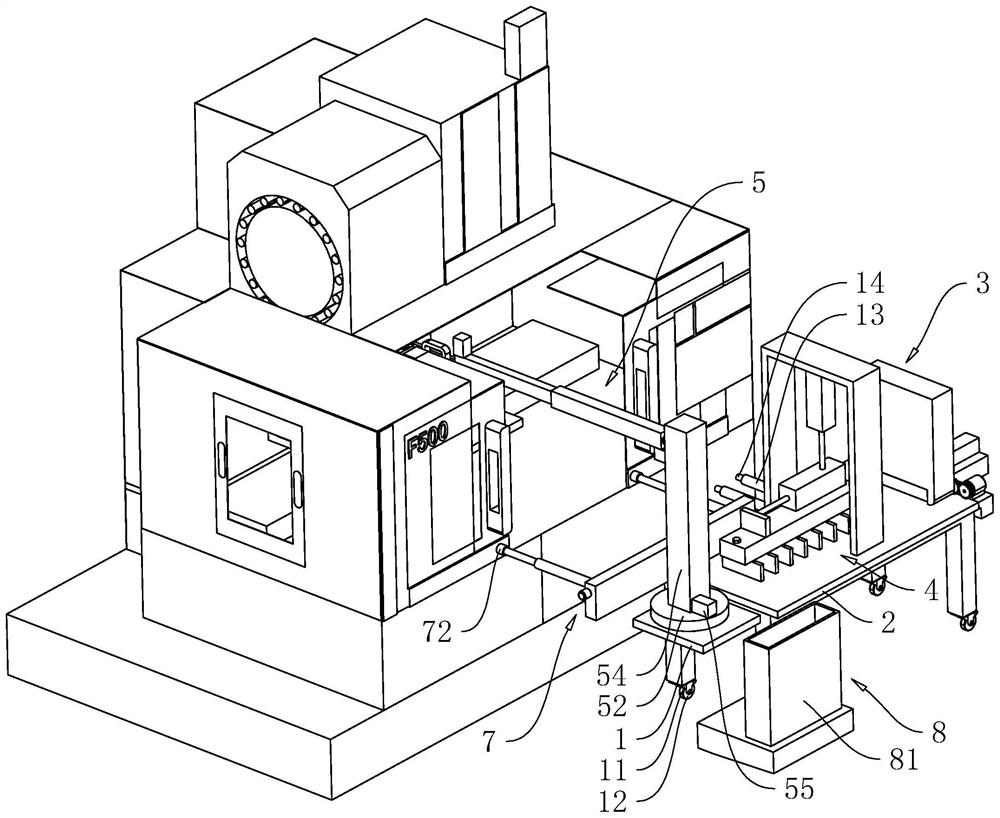

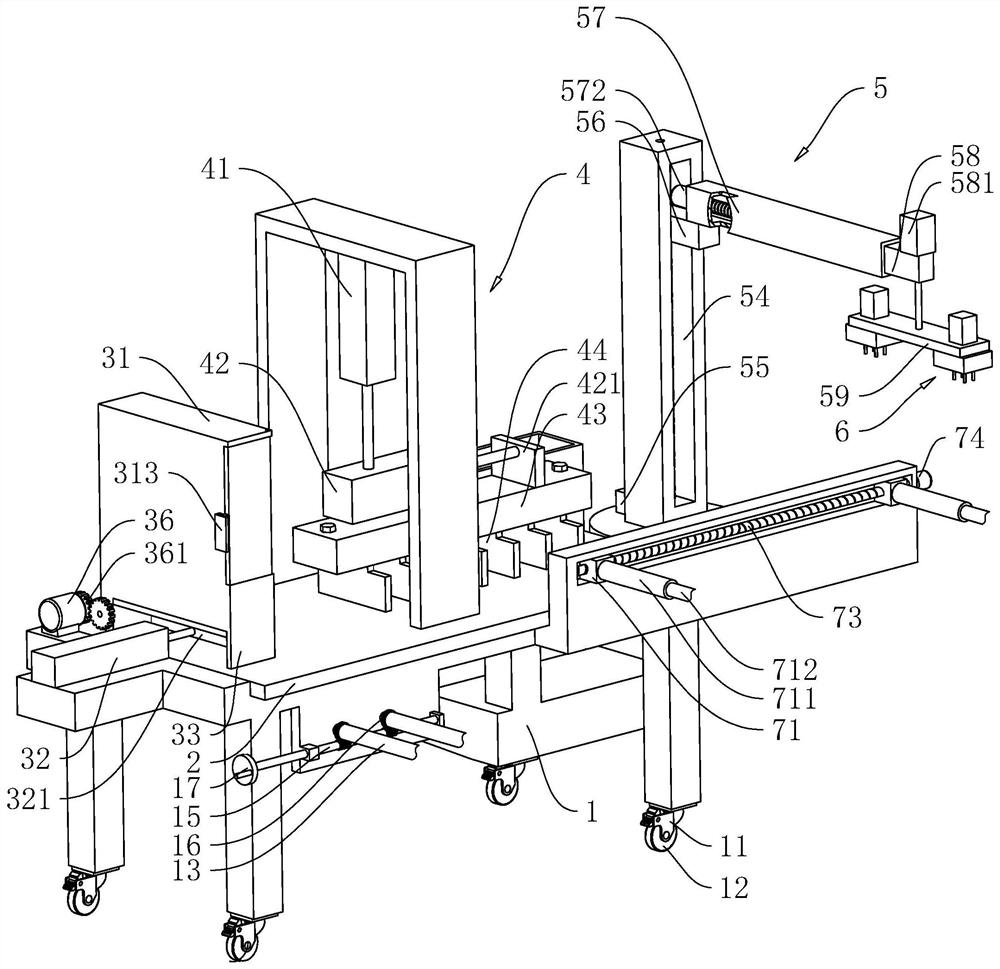

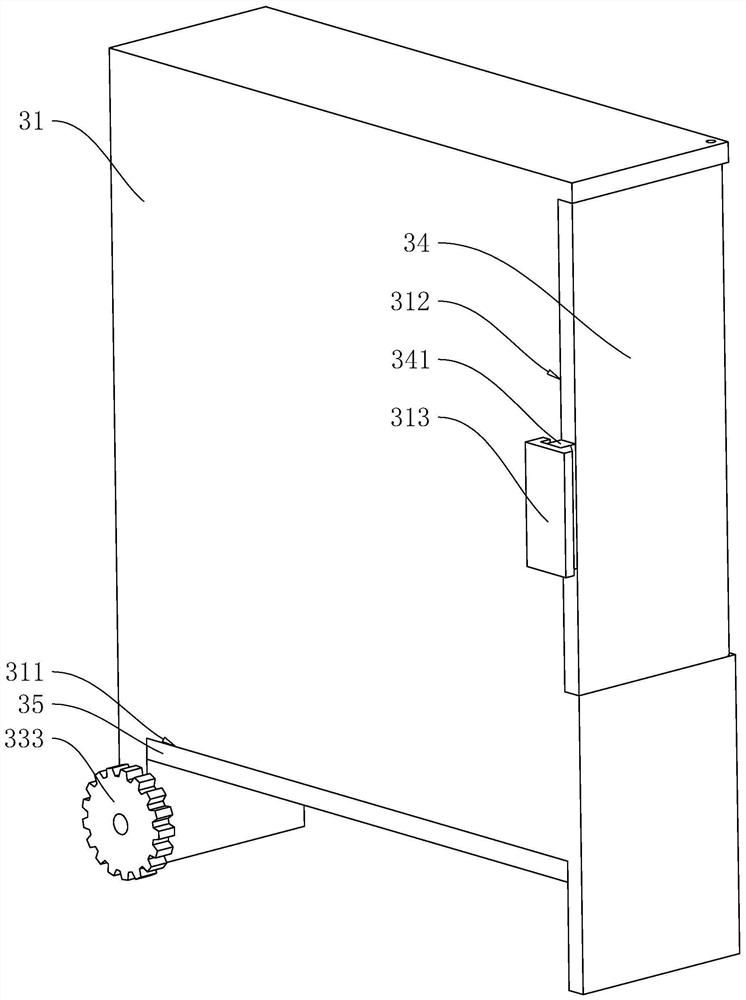

[0040] The following is attached figure 1 -X further details the application.

[0041] The embodiment of the present application discloses a feeding device of a five-axis linkage vertical machining center, referring to figure 1 with figure 2 , including the frame 1 positioned at the safety door side of the machining center, two pairs of roller frames 11 are installed horizontally on both sides of the bottom of the frame 1, and rollers 12 are installed on the roller frames 11 to rotate vertically. The frame 1 is horizontally fixed with a sliding table 2, the sliding table 2 is provided with a feeding mechanism 3, and the frame 1 is also provided with a first pushing mechanism 4, a clamping mechanism 5, a second pushing mechanism 7 and a feeding mechanism 8 .

[0042] refer to figure 1 with figure 2 , the frame 1 is rotated and installed with two parallel and horizontal connecting pipes 13, two studs 14 corresponding to the connecting pipes 13 are welded on the side wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com