Inner core bending mechanism for wheel speed sensor

A technology of wheel speed sensor and bending mechanism, applied in the field of bending mechanism, can solve the problems of high working intensity of workers, troublesome and inconvenient use, etc., achieve high bending processing efficiency, high unloading efficiency, and reduce weight, cost and power. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them.

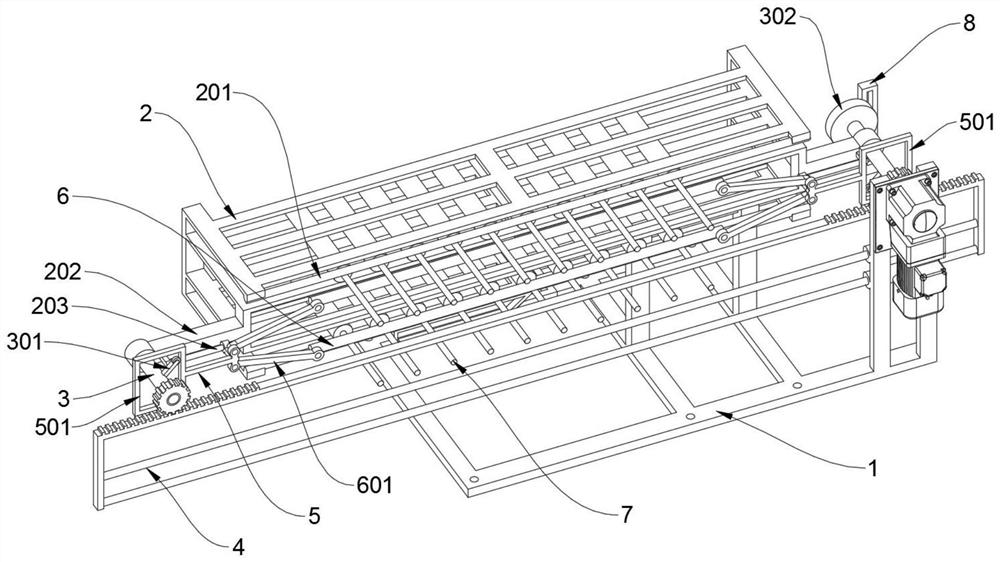

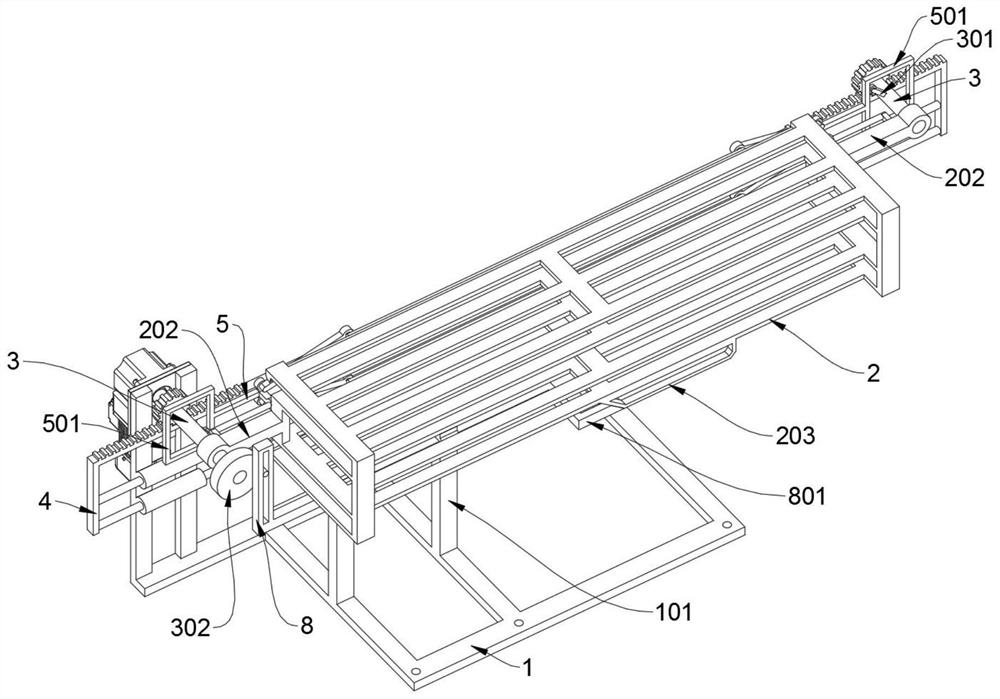

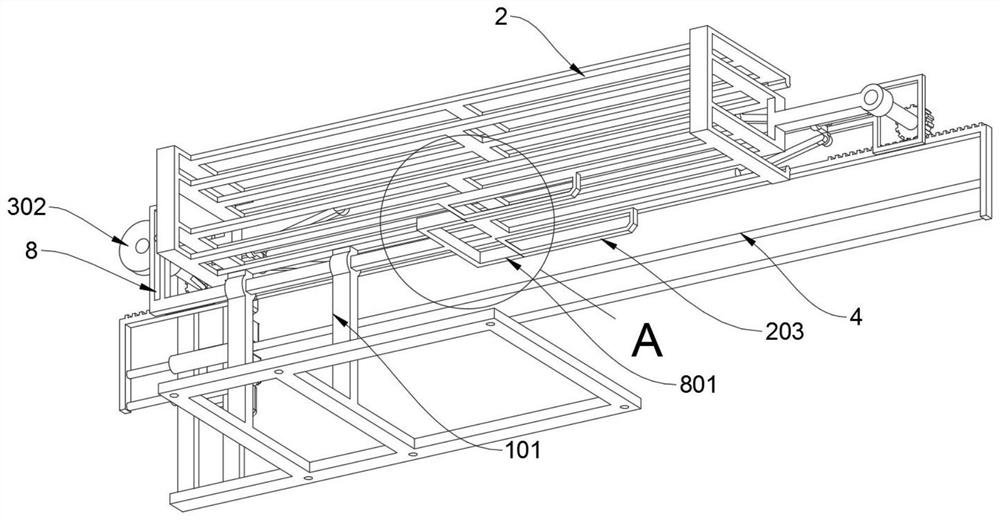

[0029] see Figure 1 to Figure 8 , an embodiment provided by the present invention: a wheel speed sensor inner core bending mechanism, including a base 1, the base 1 includes a vertical support rod 101, the base 1 has a rectangular structure as a whole, and two places are welded at intervals in the middle of the top end Vertical support rods 101, an L-shaped drive rod 8 is inserted through the top sections of the two vertical support rods 101, and the right end of the base 1 is locked and vertically supported. There is a motor on the shaft of the reducer of the motor A rotating shaft 3 is installed; a positioning frame 2 is installed on the right rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com