Hole detection and straightening equipment and detection and straightening method

A technology for testing equipment and equipment, which is applied in the field of mechanical processing and can solve problems such as principle errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

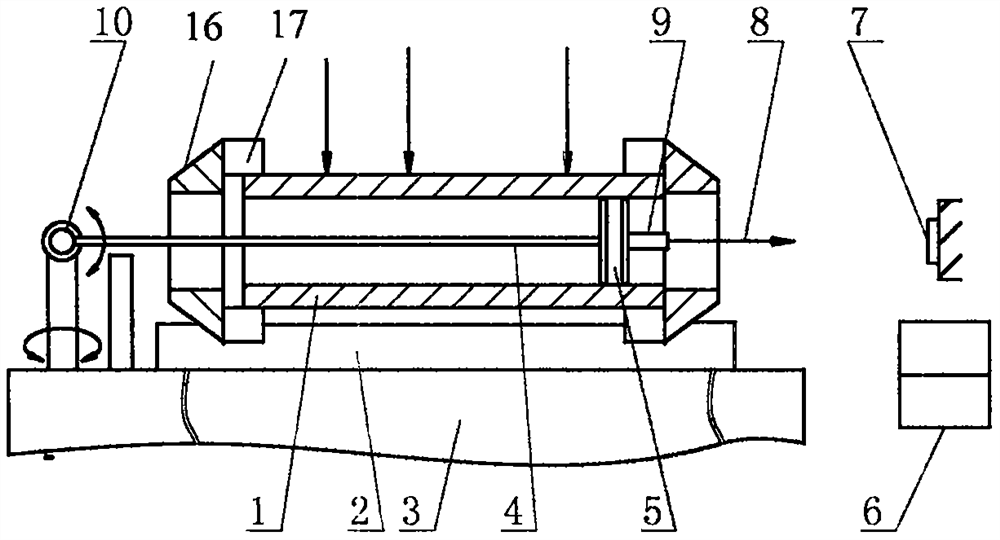

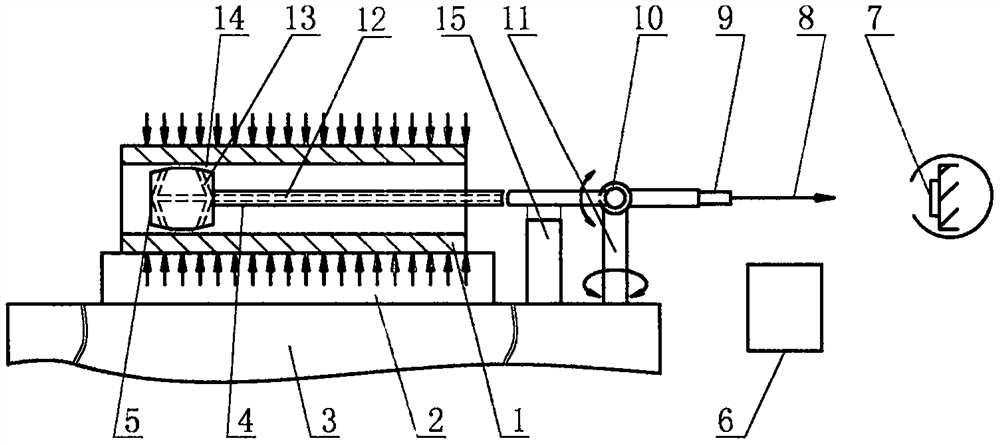

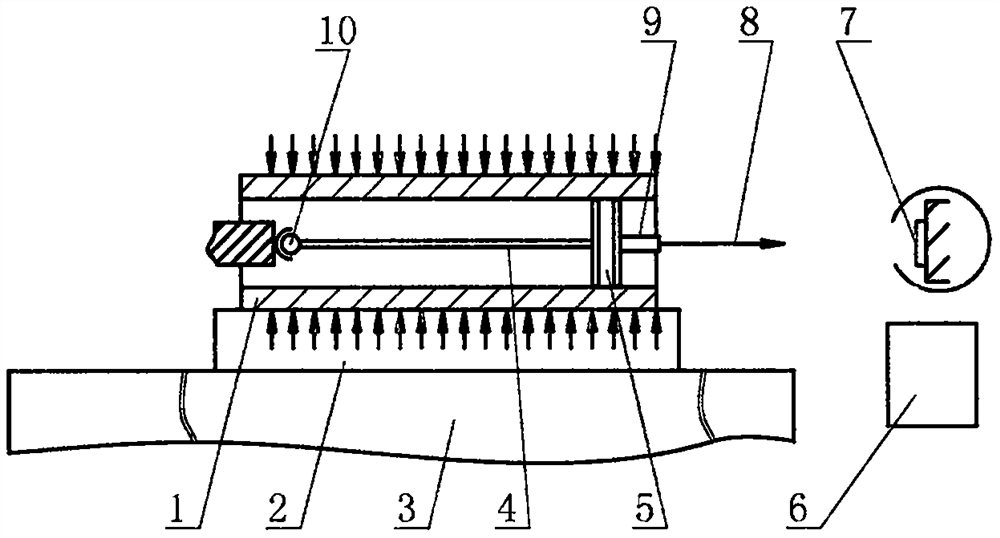

Examples

specific Embodiment approach

[0049] The specific implementation of the probe head: the probe head is in contact with the inner wall of the hole along a range of 360 degrees or within a range of less than 360 degrees; or, the probe head is not in direct contact with the hole wall, and there is a pressurized gas between the two.

[0050] Specific implementation of the detection rod: there is no hole or a hole in the detection rod.

Embodiment approach

[0051] Fulcrum implementation: The fulcrum is connected to a fixed object or connected to a rotatable object (eg, a support).

[0052] Detection part implementation mode: integral type or split type.

[0053] Afterburner mode: one-point afterburner, two-point afterburner, multi-point afterburner.

[0054] When using the moment of inertia method to evaluate the straightness of the hole, the Z-axis or X-axis or Y-axis of the coordinate system of the testing equipment is consistent with the direction of the hole axis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com