Container, furnace and method for heat treatment of a powder mixture

A technology of powder mixture and heat treatment process, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems such as limited service life, high mechanical compressive stress, adhesion, etc., and achieve increased production, low mechanical load, and increased service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

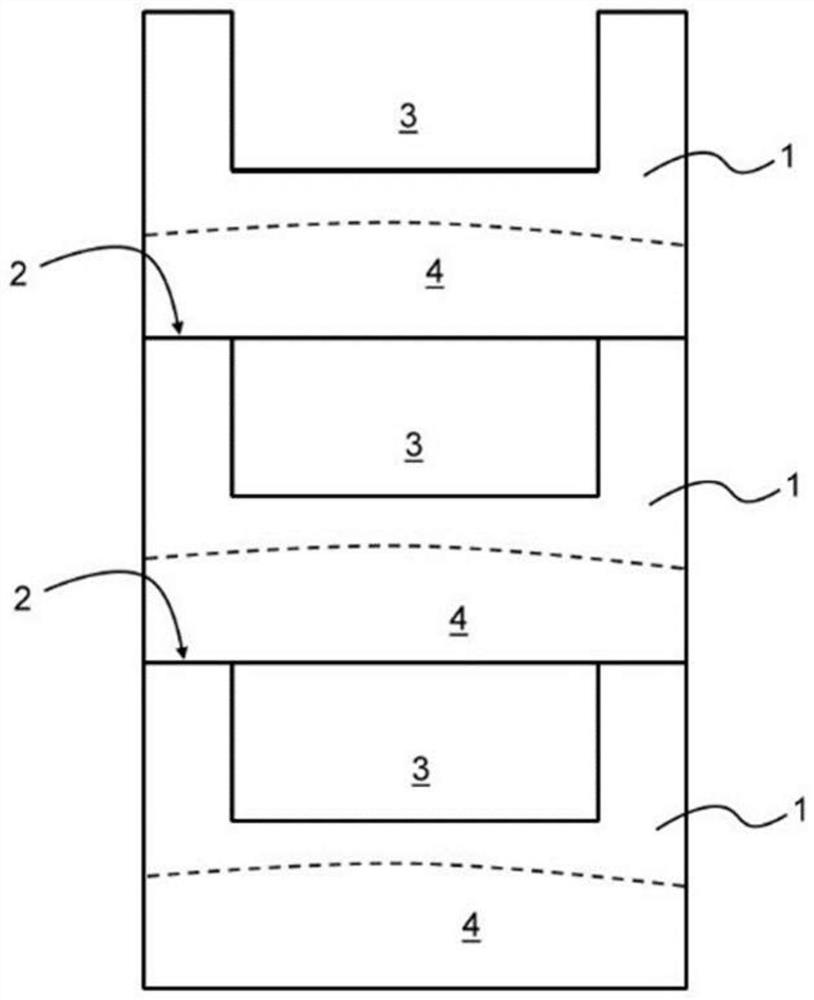

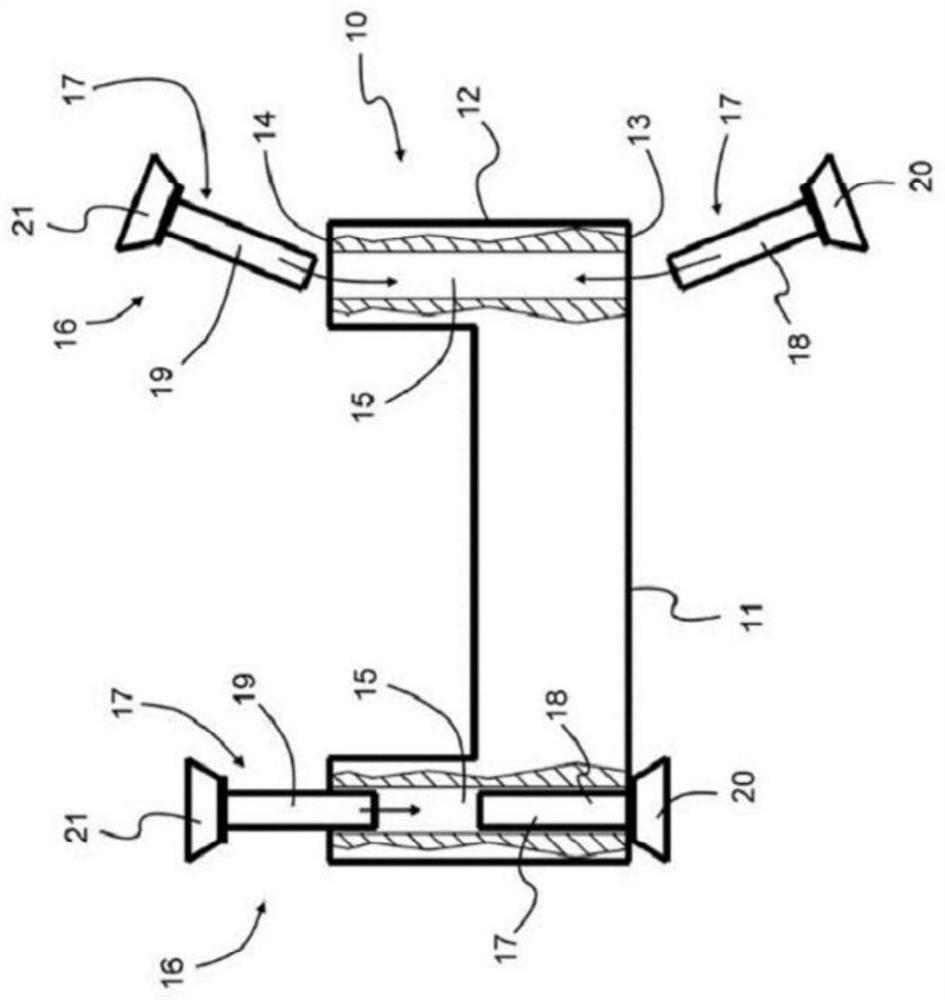

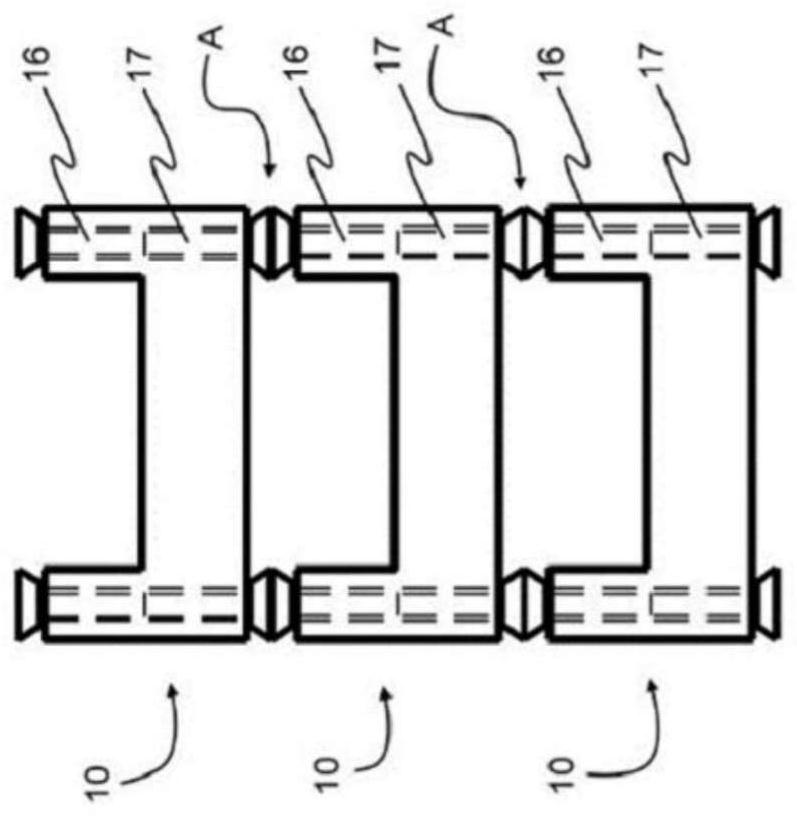

[0032] exist Figure 2a , Figure 2bA first exemplary embodiment of the present invention is shown in . The containers 10 shown here are all of one-piece design and have a bottom 11 and a wall 12, whereby said container 10 is designed in the shape of a bowl for containing the powder mixture. The wall 12 has a lower edge 13 and an upper edge 14 and the receptacle in the form of a hole 15 passes between said lower edge and an upper edge. The bore 15 serves to receive a spacer 16 which, in the exemplary embodiment shown, is designed in two parts and has a strut 17 consisting of a lower strut part 18 and an upper strut part 19 . The lower strut portion 18 is connected to the foot 20 and the upper strut portion 19 is connected to the head 21 . In order to detachably connect the spacer 16 to the container 10, the lower strut portion 18 is inserted into the hole 15 from below. The upper strut portion 19 is inserted into the hole 15 at the upper edge 14 until the upper strut portio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com