Composite material shielding case

A technology of shielding chassis and composite materials, which is applied in the aerospace field, can solve the problems of electromagnetic interference of control circuits, high integration of electronic circuits, and impact on flight safety, etc., and achieves excellent electromagnetic shielding effect, light weight, and strengthen the effect of structural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

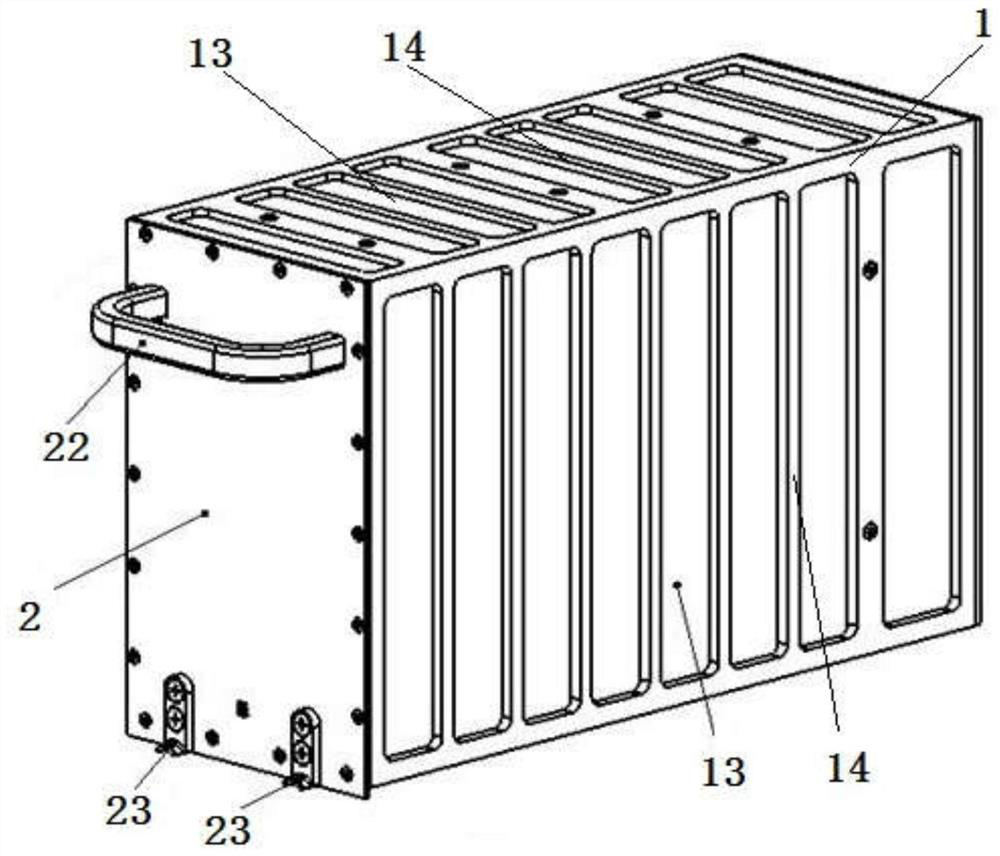

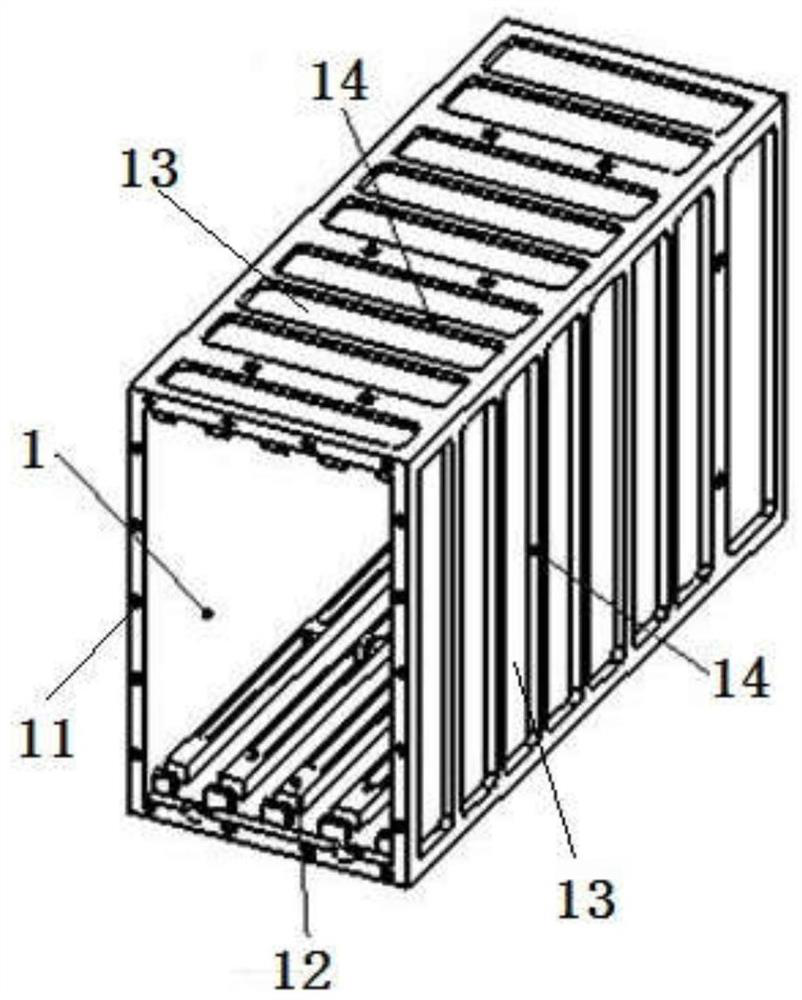

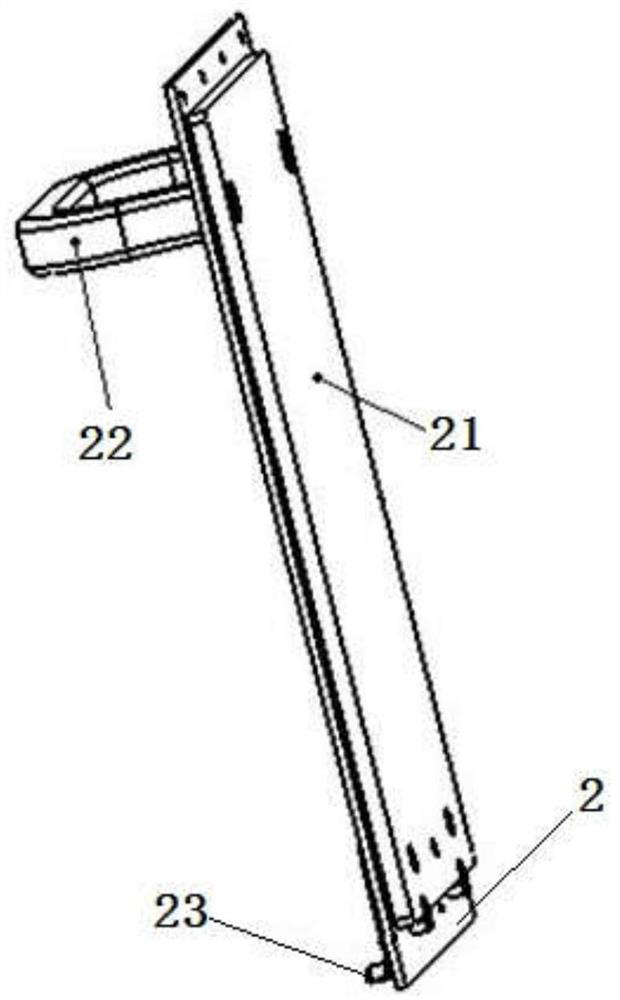

[0024] like Figure 1-Figure 6 As shown, a shielding case made of composite materials includes a case body 1, a front cover 2 and a rear cover 3, the main body of the case body 1 is a hollow cuboid with two ends open, and the left and right ends of the case body 1 have Threaded mounting holes 11, the front cover 2 and the rear cover 3 have fixed holes that match the positions of the threaded mounting holes 11, and the front cover 2 and the rear cover 3 are covered by screws and threaded mounting holes 11. Openings at both ends of the box body 1, the junction of the box body 1 and the front cover plate 2 and the rear cover plate 3 is also provided with a conductive gasket 4 to ensure complete electromagnetic shielding and no leakage. The inner wall of the box body 1 is provided with several For the metal slots 12 used to fasten slot-type electronic devices, each pair...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com