A cleaning device for wafers

A technology for cleaning devices and wafers, which is applied in the direction of cleaning methods using liquids, cleaning methods using tools, cleaning methods and utensils, etc., which can solve the problems of low cleaning agent use efficiency, time-consuming and labor-intensive use, and improve kinetic energy utilization. , Improve the cleaning effect and avoid the effect of empty spray

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

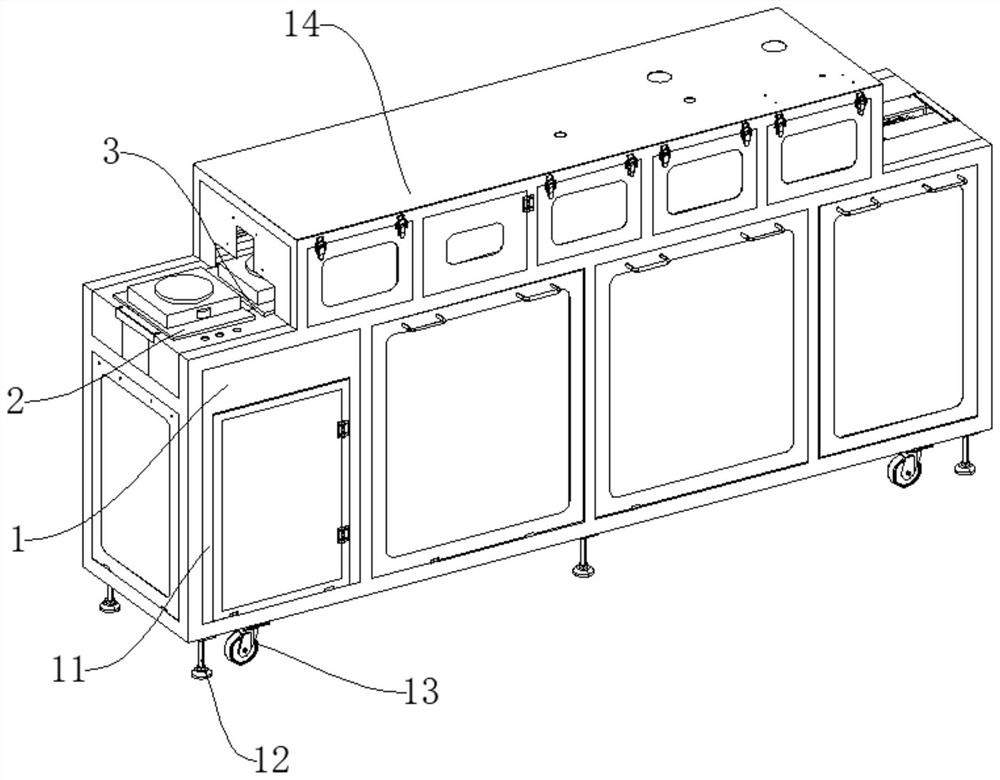

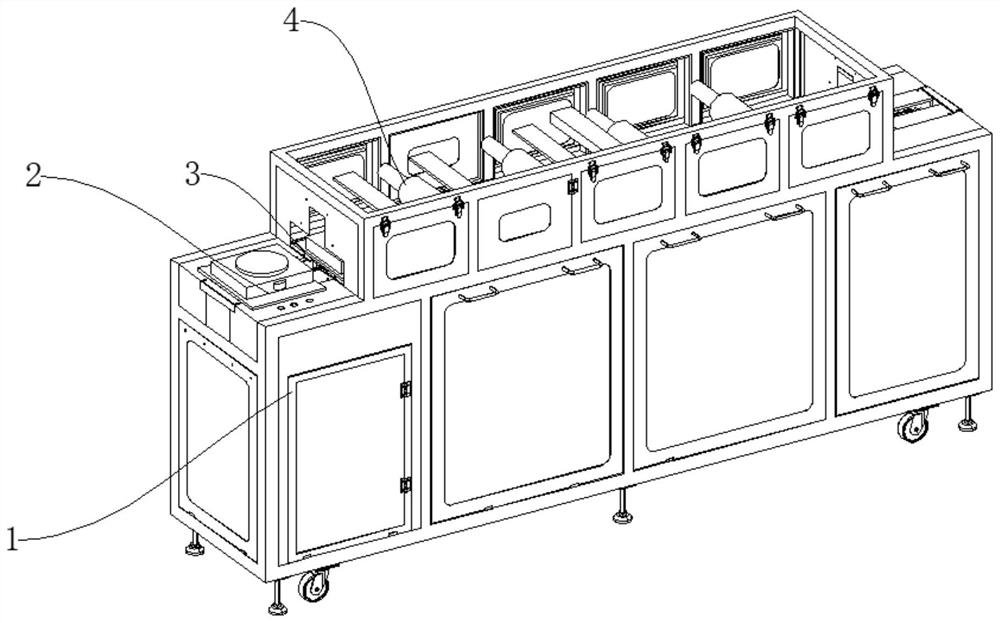

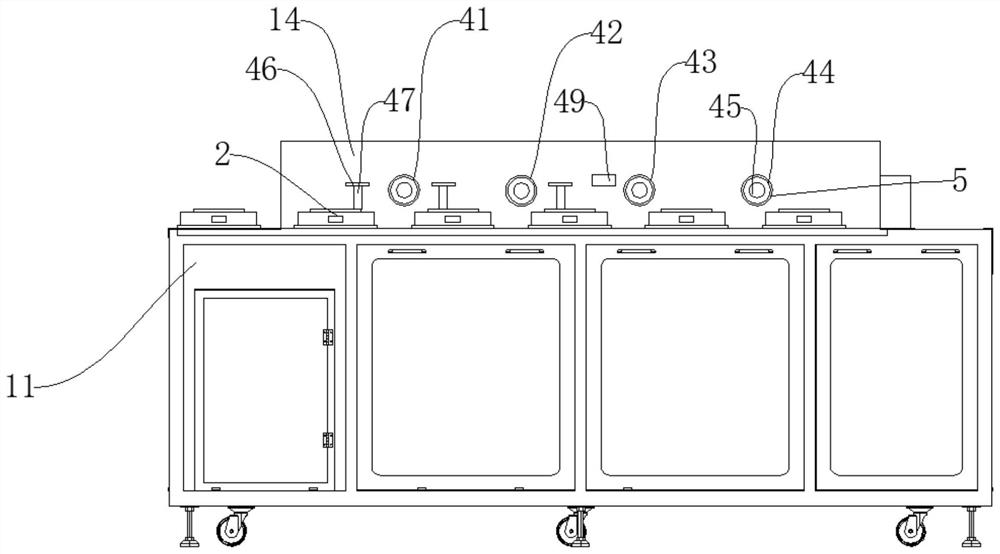

[0048] like Figure 1-Figure 9 As shown, a cleaning device for wafers includes a protection mechanism 1, a fixing mechanism 2, a conveying mechanism 3, and a cleaning mechanism 4. The protection mechanism 1 is provided with a conveying mechanism 3, and the upper end of the conveying mechanism 3 is connected with a fixing mechanism 2, A cleaning mechanism 4 is arranged on the upper side of the fixing mechanism 2, the cleaning mechanisms 4 are connected by a linkage mechanism 5, and the power ends of the cleaning mechanism 4 and the transmission mechanism 3 are connected to the power mechanism 6;

[0049] The protection mechanism 1 includes a circulating water tank 11, a first fixed seat 12, a universal wheel 13, and a cleaning box 14. The upper end of the circulating water tank 11 is provided with a cleaning box 14, the circulating water tank 11 is provided with a water tank and a circulating pump, and the lower end of the circulating water tank 11 is provided with a water tank ...

Embodiment 2

[0056] like Figure 10 The difference between this embodiment and Embodiment 1 is:

[0057] The linkage mechanism 5 includes a driving bevel gear 511, a driven bevel gear 512, a worm 513, and a worm wheel 514. The driving bevel gear 511 is connected to the first central shaft 45, the lower end of the driving bevel gear 511 meshes with the driven bevel gear 512, and the driven bevel gear 512 A worm 513 is connected to the worm, and three worm gears 514 are engaged with the worm 513. When multiple central shafts 45 are required to rotate, the servo motor 61 transmits power to the first central shaft 45 through the first sprocket group 62, and then passes The cooperation of the driving bevel gear 511 and the driven bevel gear 512 transmits the power to the worm 513 , and the subsequent central shaft 45 is rotated by the cooperation of the worm 513 and the worm wheel 514 .

[0058] A method for using a cleaning device for wafers, comprising the following steps:

[0059] a) Plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com