A kind of anti-pollution sample processing system

A processing system and anti-pollution technology, applied in the field of anti-pollution sample processing systems, can solve the problems of increasing the risk of cross-contamination between samples, increasing the risk of environmental pollution, etc., so as to reduce the risk of sample leakage and cross-contamination, and reduce pollution. Environmental risk and effect of reducing the risk of mishandling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further illustrate the technical solution of the present invention, the present invention will be further described below through examples.

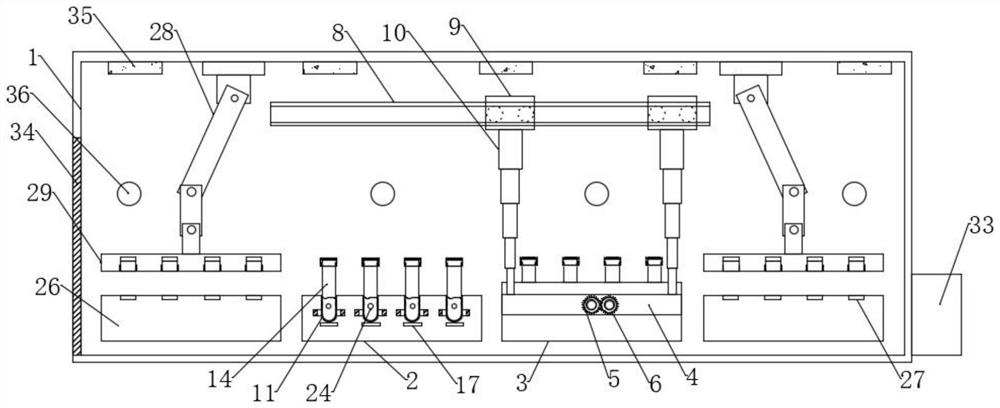

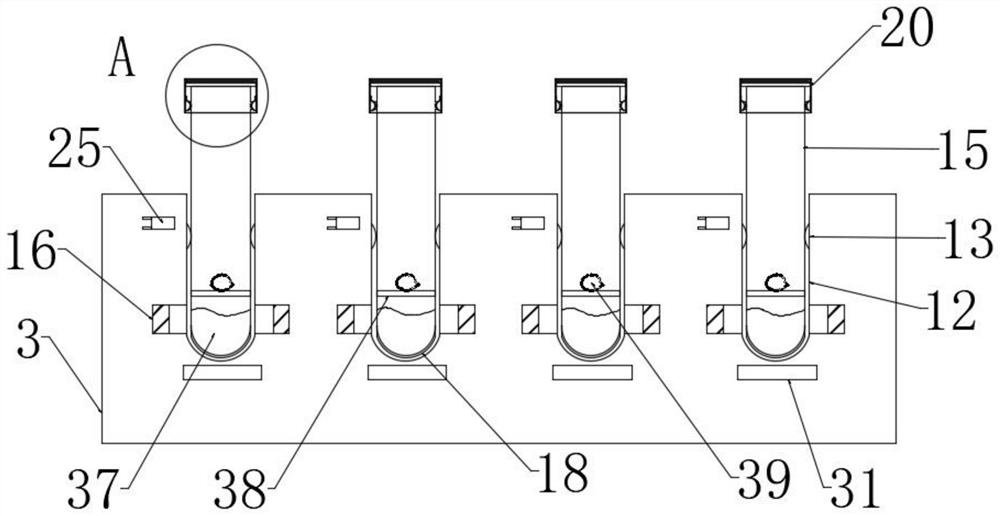

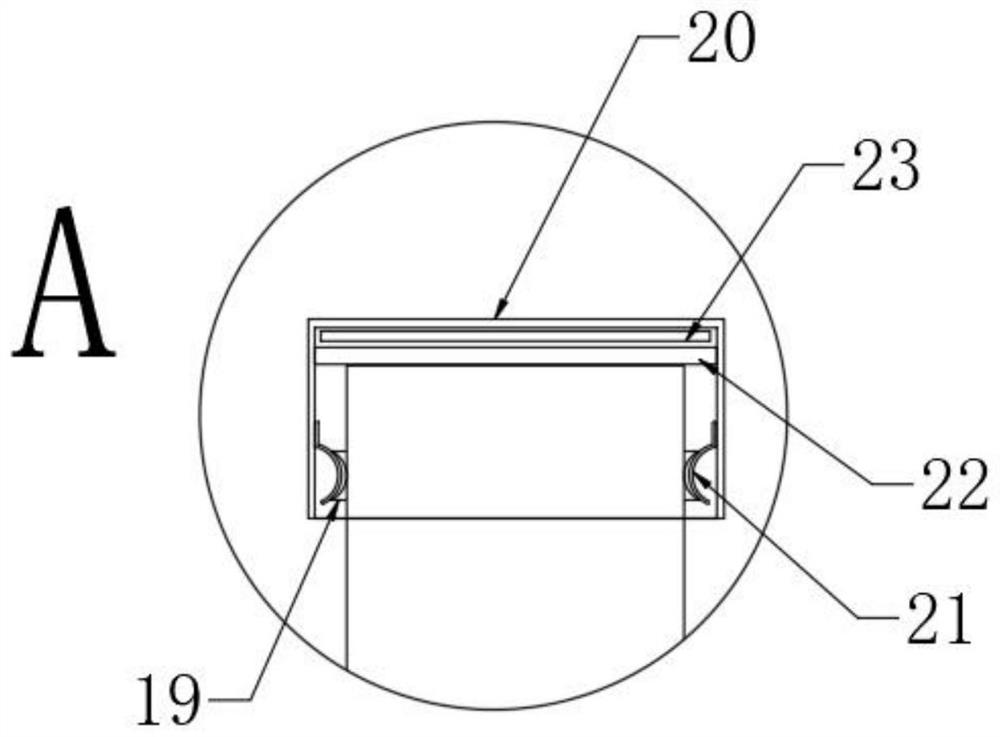

[0028] Such as Figure 1 to Figure 6As shown, an anti-pollution sample processing system includes a closeable operating room 1, a switchable door is arranged on the side wall of the operating room 1, and inlaid on the front and rear side walls of the operating room 1 are The semiconductor refrigeration sheet 36 is used to cool down the inside of the operating room 1, and a plurality of ultraviolet lamps 35 are also arranged on the top of the operating room 1 for self-sterilizing during the non-use period of the operating room 1. In the middle of the chamber 1, a storage tube base 2 and a reaction tube base 3 are arranged side by side, the storage tube base 2 is fixedly arranged at the bottom of the operation room 1, and the front and rear sides of the reaction tube base 3 are provided with mounting plates 4. A rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com