Electromagnetic ammunition capable of being launched by conventional gunpowder launcher

An ammunition and electromagnetic technology, which is applied to weapons, ammunition, projectiles and other directions without explosives, can solve the problems of insufficient export speed of gunpowder launching technology, incompatibility of artillery and ammunition with electromagnetic propulsion, etc., to improve anti-armor capability and enhance strike capability. , good concealment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

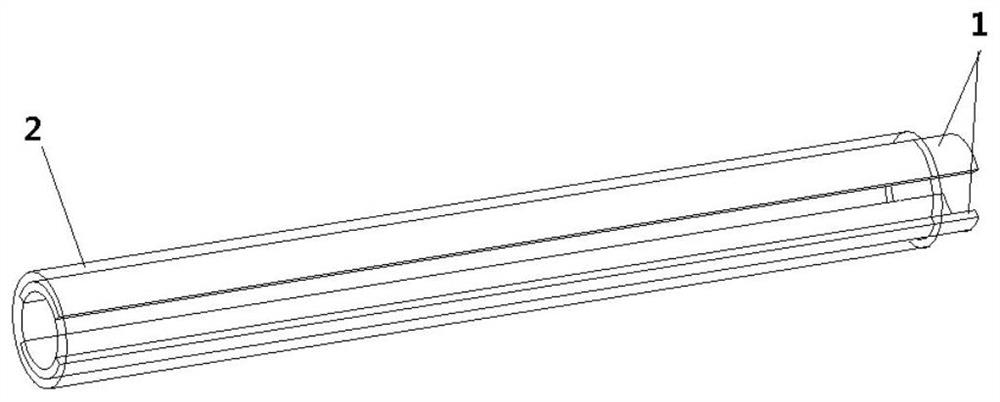

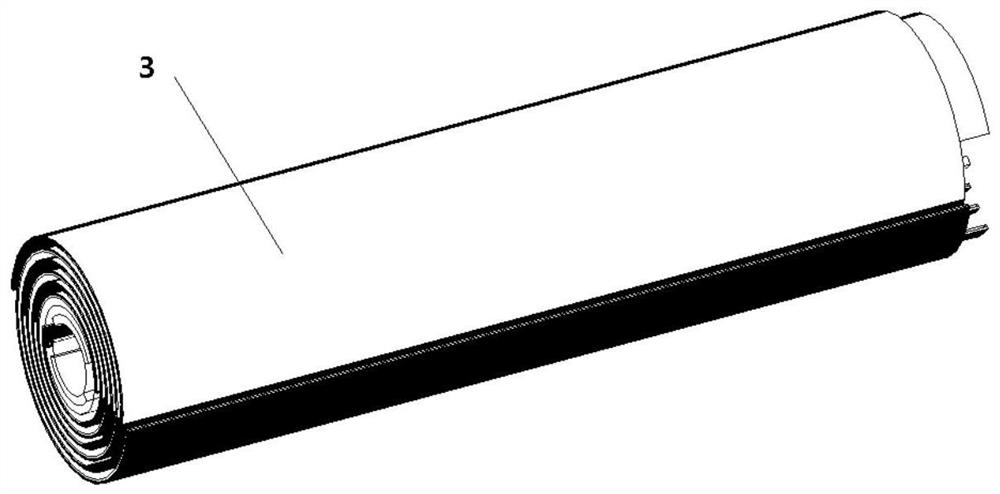

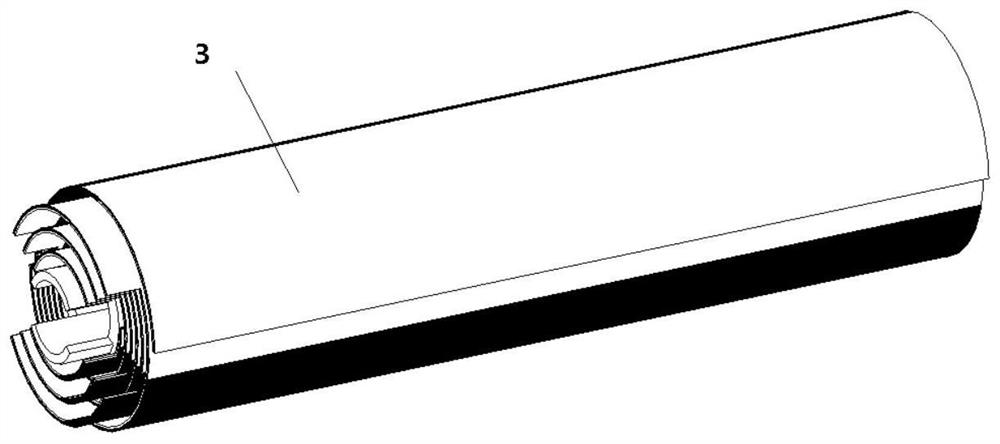

[0019] The invention proposes an electric ammunition that can be used in traditional gunpowder launchers, which utilizes the advantage of electromagnetic propulsion to break through the limit speed of gunpowder launch, and is compatible with traditional artillery launch. Two parallel tile-shaped metal strips, the metal can be made of copper alloy, etc., symmetrically inlaid on the inner wall of the insulating sleeve, the insulating sleeve can be made of insulating materials such as epoxy glass fiber reinforced plastics, the outlet of the tile-shaped metal strip and the insulating sleeve The barrel is flat, a part of the tail protrudes, and a cylindrical cavity is formed inside, which can be called a firing cavity. The insulating sleeve is tightly wound with a composite film made of two layers of conductive foil and insulating foil material. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com