Coupling system for coal mining machine on fully mechanized coal mining face of coal mine and geological model

A fully mechanized mining face and geological model technology, applied in ground mining, slitting machinery, earthwork drilling and mining, etc., can solve the problems of inability to dynamically adjust the attitude of the shearer, complicated operation, and low intelligence, and achieve the goal of improving intelligence The effect of mining level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

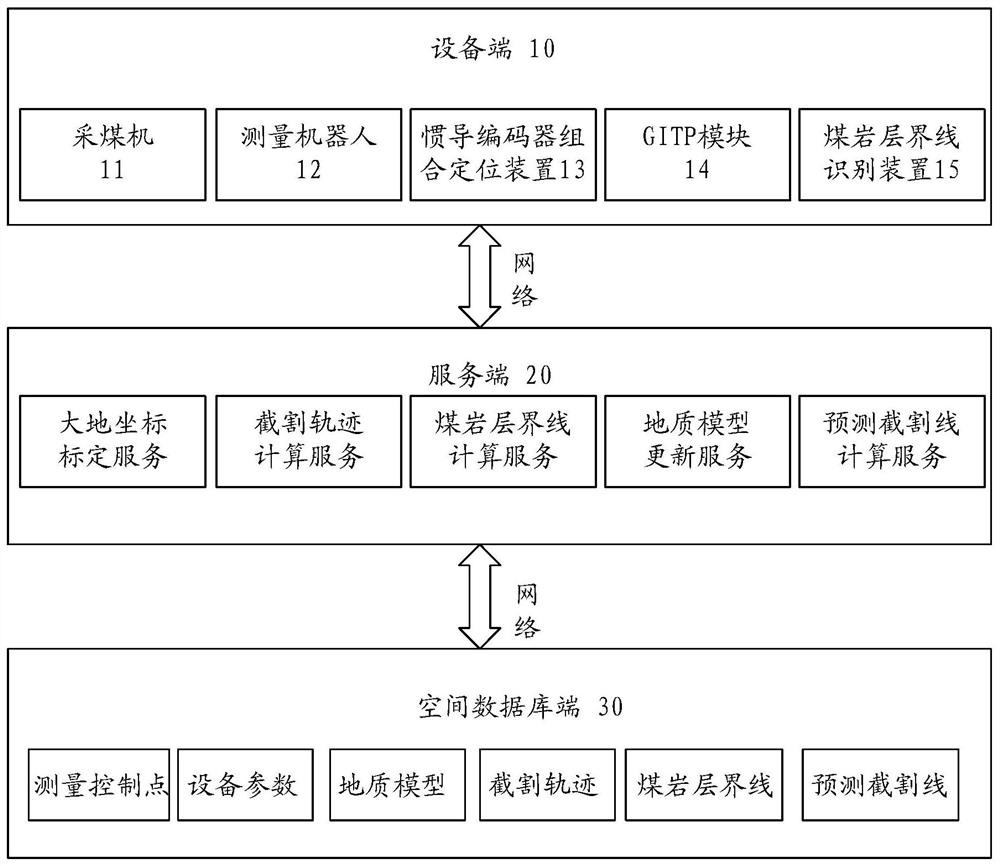

[0027] figure 1 It is a block diagram of a coupling system of a shearer and a geological model in a fully mechanized coal mining face according to an embodiment of the present application.

[0028] refer to figure 1 As shown, the coupling system provided by this embodiment is applied to the intelligent fully mechanized mining face of the coal mine, including the equipment end 10 , the server end 20 and the spatial database end 30 . The equipment side, the server side and the spatial database side realize the connection and information interaction through the network equipment, that is, each side is equipped with corresponding network communication equipment.

[0029] The equipment end includes a coal mining machine 11 and a measuring robot 12 on the fully mechanized mining face, and also includes an inertial navigation encoder combined positioning device 13 , a GITP module 14 and a coal seam boundary identification device 15 installed on the coal mining machine.

[0030] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com