A preparation method of aluminum alloy powder suitable for laser additive manufacturing

A technology of laser additive material and aluminum alloy, which is applied in the direction of additive manufacturing, additive processing, metal processing equipment, etc., can solve the problems of expensive and difficult Sc, and achieve the suppression of crack formation, good grain refinement, and guaranteed use Economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

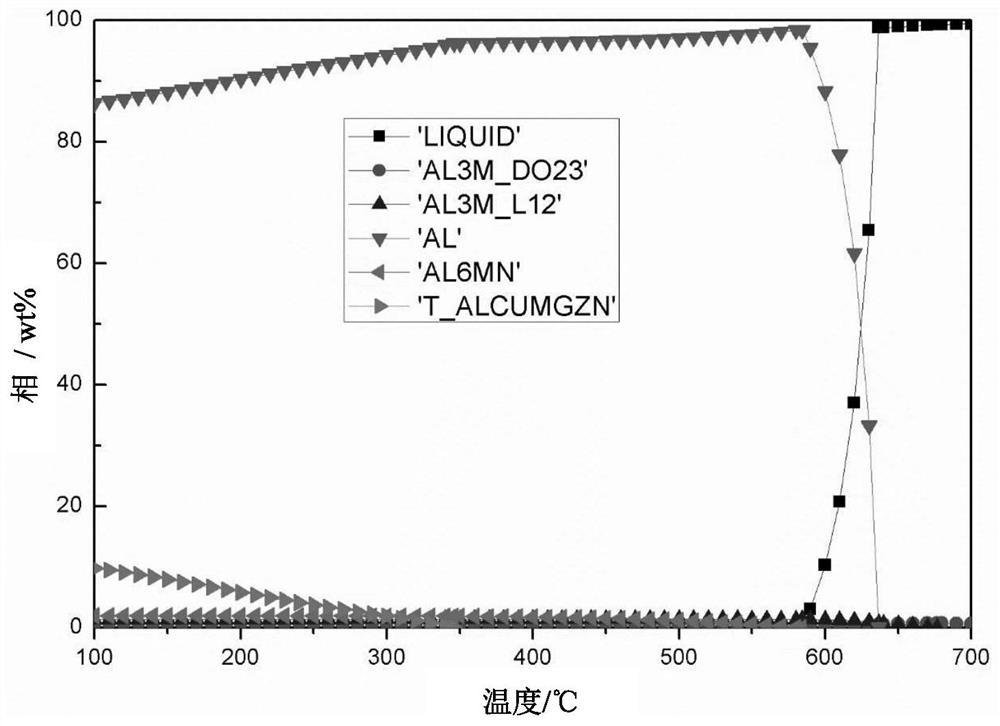

[0048] Example 1Al-3.0Mg-0.5Mn-0.15Cu-0.6Sc-2.0Zn-0.3Zr

[0049] This example provides a new type of high-strength aluminum alloy powder suitable for 3D printing, and its composition includes: 3% Mg, 2% Zn, 0.5% Mn, 0.15% Cu, 0.6% Sc, 0.3% Zr, the balance being Al and unavoidable impurities.

[0050] The high-strength aluminum alloy powder provided in this example is prepared by the following method:

[0051] Alloy element raw materials are weighed according to the chemical composition distribution ratio. The alloy raw materials used are pure aluminum ingots, pure zinc blocks, aluminum-copper master alloys, aluminum-zirconium master alloy blocks, aluminum-manganese master alloy blocks and aluminum-magnesium-scandium master alloys. alloy block. Before use, the pure aluminum ingots are subjected to surface treatment such as machining or grinding (wiping with acetone or alcohol if necessary), and then baked together with other raw materials in a muffle furnace (200°C×2h).

[0...

Embodiment 2

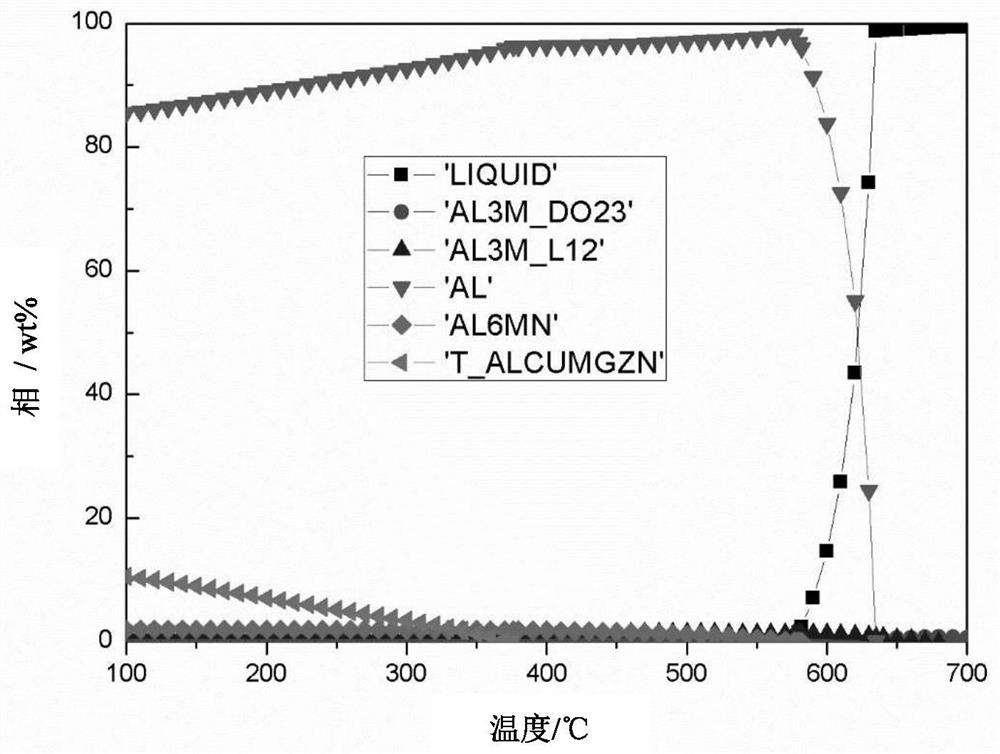

[0057] Example 2Al-3.8Mg-0.6Mn-0.15Cu-0.8Sc-3.0Zn-0.4Zr

[0058] This example provides a new type of high-strength aluminum alloy powder suitable for 3D printing, and its composition includes: 3.8% Mg, 3% Zn, 0.6% Mn, 0.15% Cu, 0.8% Sc, 0.4% Zr, the balance being Al and unavoidable impurities.

[0059] The aluminum alloy powder was prepared by a preparation method similar to that of Example 1, and the aluminum alloy powder was prepared into a molded article by a molding method similar to that of Example 1.

[0060] figure 2 Show the equilibrium phase diagram of the Al-3.8Mg-0.6Mn-0.8Sc-3.0Zn-0.4Zr aluminum alloy of the present embodiment, the ordinate is the weight percentage (wt%Phase) of each phase, and the abscissa is temperature / °C ( Temperature / °C). Similar to the result of Example 1, such as figure 2 As shown, the solidification temperature range of the aluminum alloy is 636°C-584°C. During the solidification process of the aluminum alloy, the order of the precipit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com