Hydraulic guide pipe flaring machine

A flaring machine and conduit technology, which is applied to metal processing equipment, feeding devices, safety equipment, etc., can solve the problems of no positioning and clamping mechanism, fixture wear, and flaring accuracy decline, etc. The effect of flaring accuracy and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

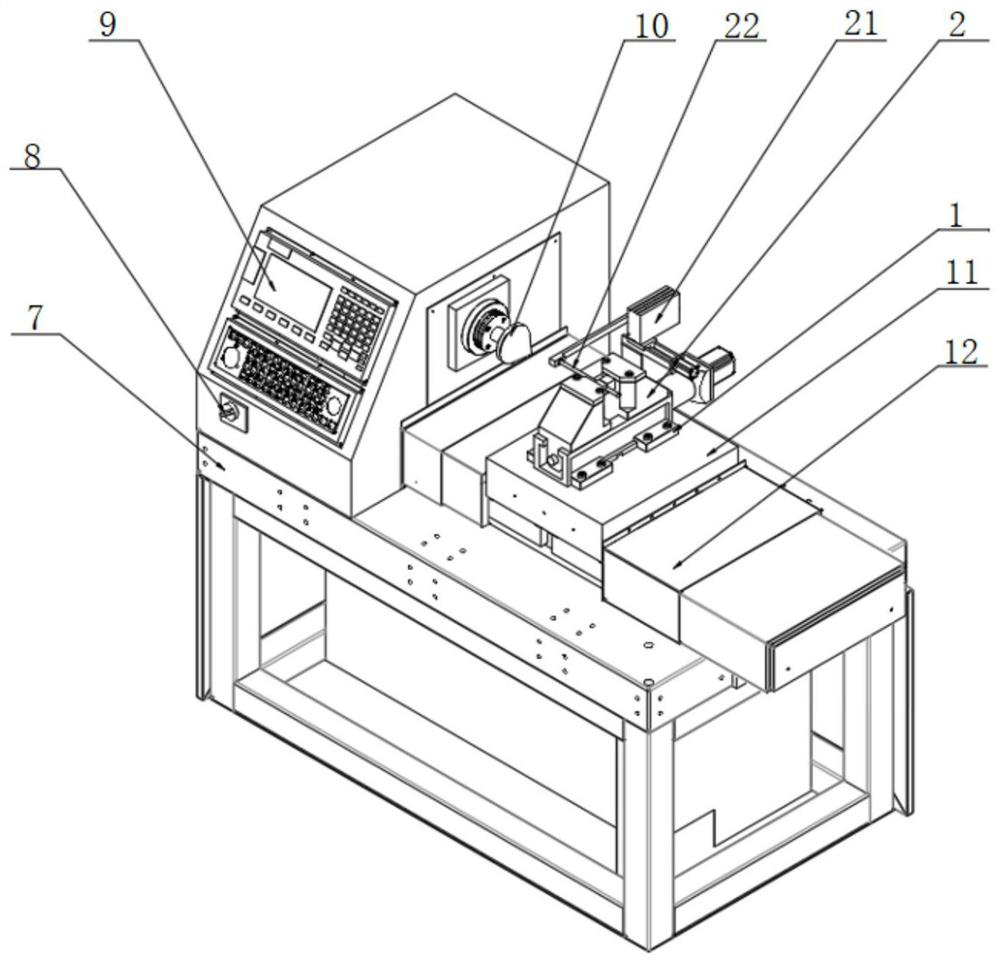

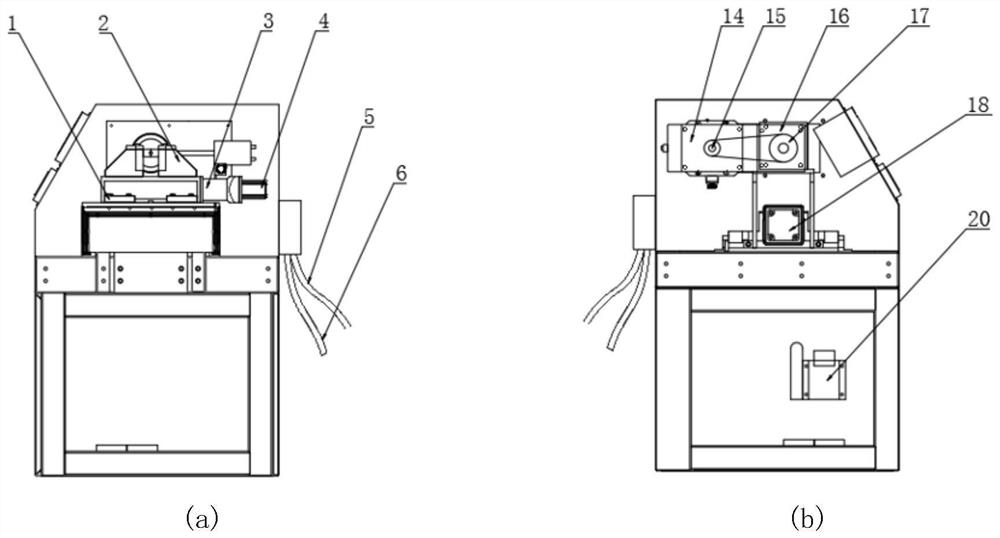

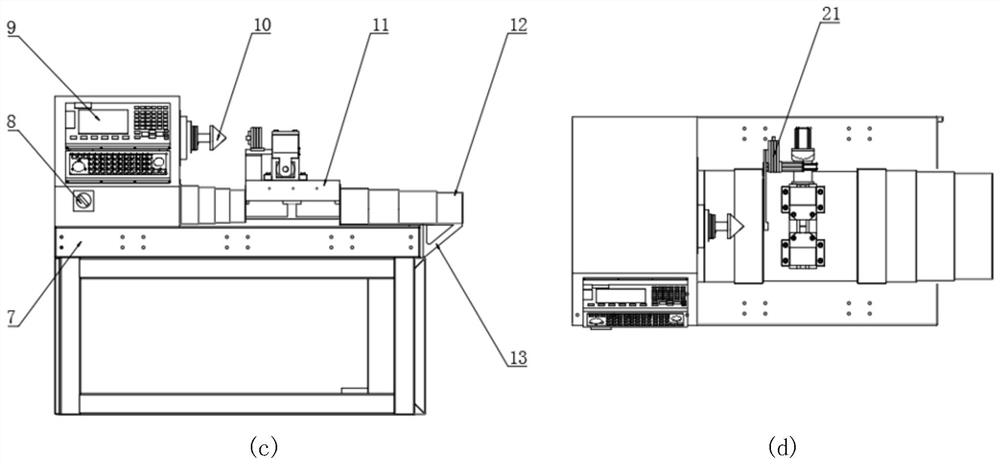

[0037] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0038] This embodiment provides a hydraulic conduit flaring machine, which can effectively determine the feed rate and ensure effective clamping of the hydraulic conduit. At the same time, the automatic flaring process can be realized by using the numerical control panel for numerical control.

[0039] The flaring machine includes: installation pressure plate 1, fixture 2, power cord 5, air source connection 6, base body 7, switch 8, numerical control panel 9, expansion cone 10, sliding plate A11, telescopic protective plate 12, protective plate mounting frame 13. Main shaft servo system, oil tank 20, hydraulic conduit positioning mechanism 21, ball screw A24, ball screw bearing support 25, linear guide 26, guide rail slider 27 and nut A28; fixture 2 includes: planetary reducer A3, Servo motor A4, pressing plate 202, clamping block 203, double-lock centeri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com