EL defect unmanned aerial vehicle inspection method for on-site evaluation of energy equipment

A technology for unmanned aerial vehicles and equipment, which is applied in the field of inspection methods and systems for EL defect unmanned aerial vehicles, and can solve problems such as inapplicability to high-altitude photovoltaic arrays, low detection efficiency, and poor interface contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings. It should be noted that the following embodiments are based on the technical solution and provide detailed implementation and specific operation process, but the protection scope of the present invention is not limited to this embodiment .

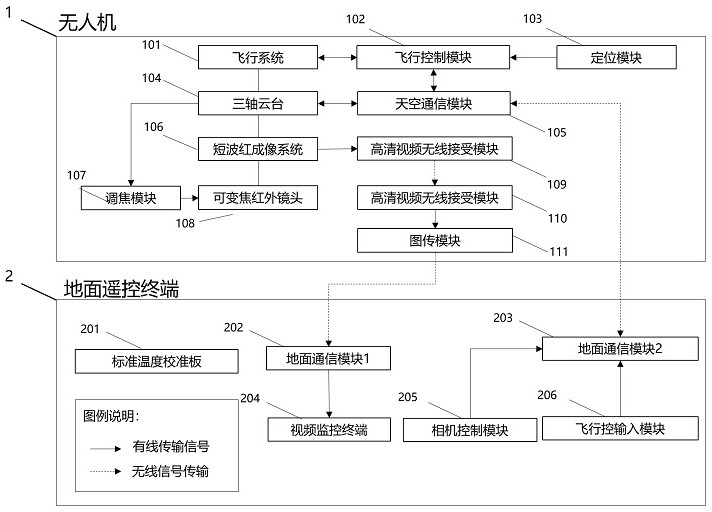

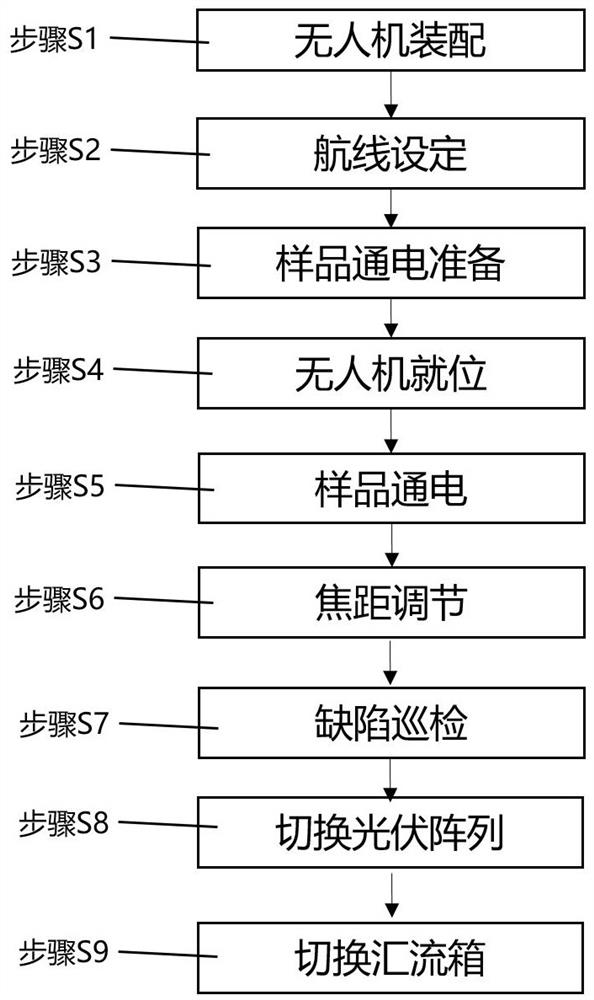

[0047] see figure 1 As shown, the structure of an EL defect UAV inspection system for on-site evaluation of energy equipment, which includes: UAV, flight system, flight control module, positioning module, three-axis gimbal, sky communication module, short-wave infrared Imaging system, image transmission module, high-definition video wireless transmitting module, high-definition video wireless receiving module, variable focus infrared lens, focusing module, temperature calibration board, ground remote control terminal, ground communication module 1, ground communication module 2, video monitoring terminal, Infrared camera focus contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com