An automatic live working lifting platform and method

A lifting platform, live work technology, applied in the direction of electrical components, cable installation, cable installation devices, etc., can solve the problems of large structure of wire strippers, inconvenient for operators to use, affecting the efficiency of installation and maintenance of power grid equipment, etc. The effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

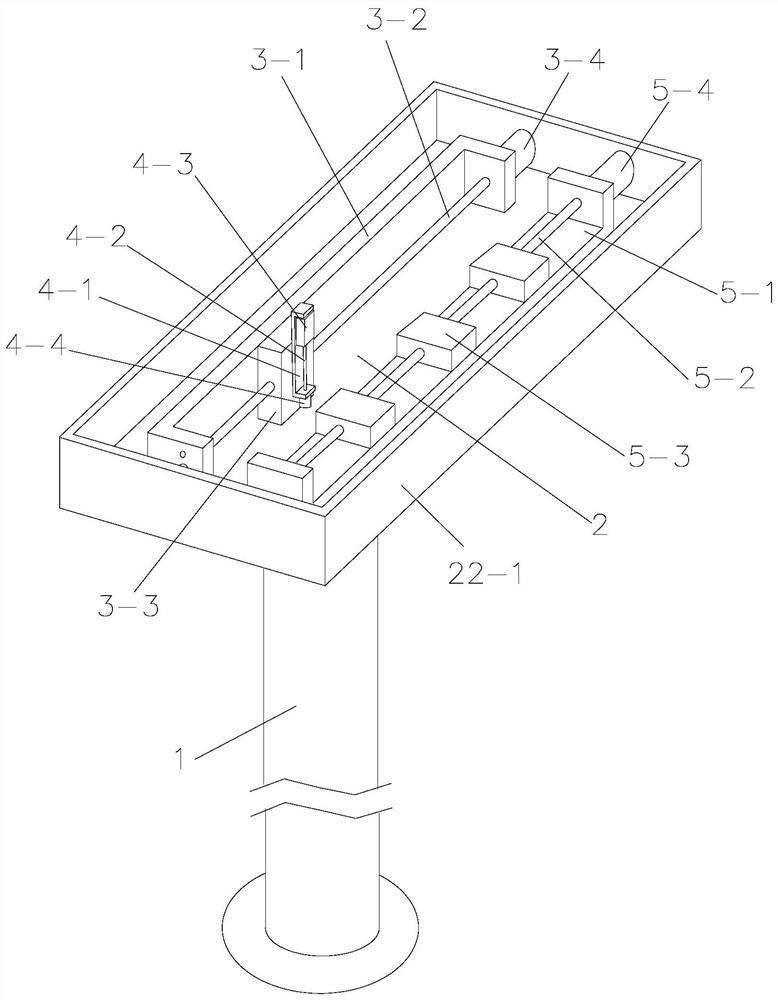

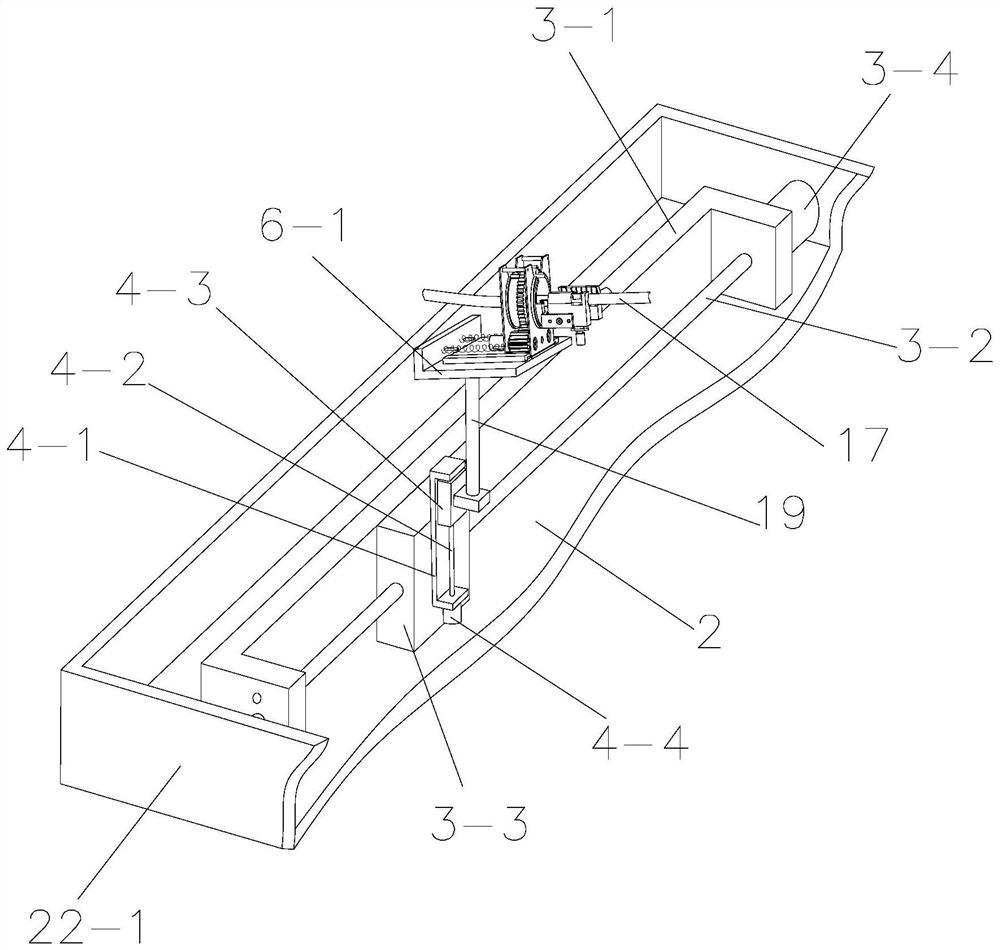

[0081] Such as figure 1 , figure 2 with image 3 As shown, as shown, the present invention includes:

[0082] Wire stripper, used to strip the coating of the lapped section of the main wire;

[0083] A lap splicer is used for lapping the branch line 18 with the lapping section of the main line that has been stripped of the cladding;

[0084] Operating platform 2, used to carry wire strippers and lappers;

[0085] Insulated lifting column 1, which is installed between the ground and the bottom surface of the operation platform 2, and is used to adjust the height of the operation platform 2;

[0086] The wire stripper includes a wire stripping device for stripping the covering layer of the main line lap and a two-axis slide table fixedly installed on the operating platform 2 for driving the wire stripping device to move horizontally. The two-axis slide table includes a horizontal linear movement mechanism fixedly installed on the operating platform 2 and a vertical linear ...

Embodiment 2

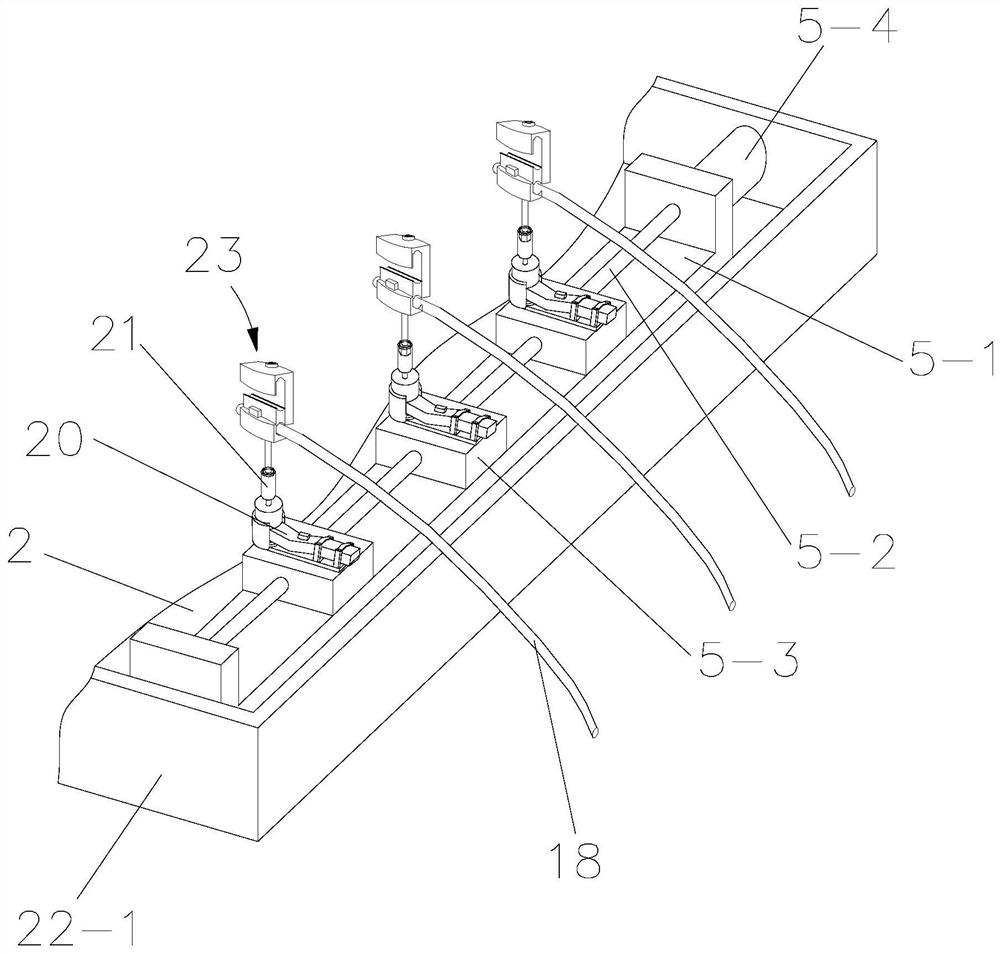

[0120] Such as Figure 8 As shown, the difference from Embodiment 1 is that in this embodiment, the start button of the electric wrench 20 is controlled by a light robot 22, and the light robot 22 is fixedly installed on the moving mechanism of the jumper.

[0121] In this embodiment, the reference model of the light robot 22 is a QR series light robot, and the structure of the QR series light robot is a vertical multi-joint robot.

Embodiment 3

[0124] Such as Figure 9 Shown, a kind of automatic live working method of the present invention comprises the following steps:

[0125] Step 1. Construction preparation:

[0126] Install the insulating lifting column 1 between the ground and the bottom surface of the operating platform 2, install the quick installation clamp assembly 23 on the branch line 18, connect the screw head of the quick installation clamp assembly 23 to the sleeve 21 of the electric wrench 20, and then , raising the height of the insulating lifting column 1 to the set height;

[0127] In this embodiment, since the quantity of the branch wires 18 is three, the quantity of the electric wrench 20 is also three, therefore, three quick installation wire clip assemblies 23 should be respectively installed on the three branch wires 18 in sequence, and the quick installation wire clips The screw head of the component 23 is docked on the sleeve 21 of the electric wrench 20. At this time, the sleeve 21 can no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com