Cross-linked polyethylene insulated halogen-free low-smoke flame-retardant rat-proof and termite-proof medium-voltage power cable

A cross-linked polyethylene, low-smoke flame-retardant technology, used in insulated cables, power cables, power cables with shielding/conducting layers, etc., can solve problems such as waste of resources, serious short circuits, and fires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

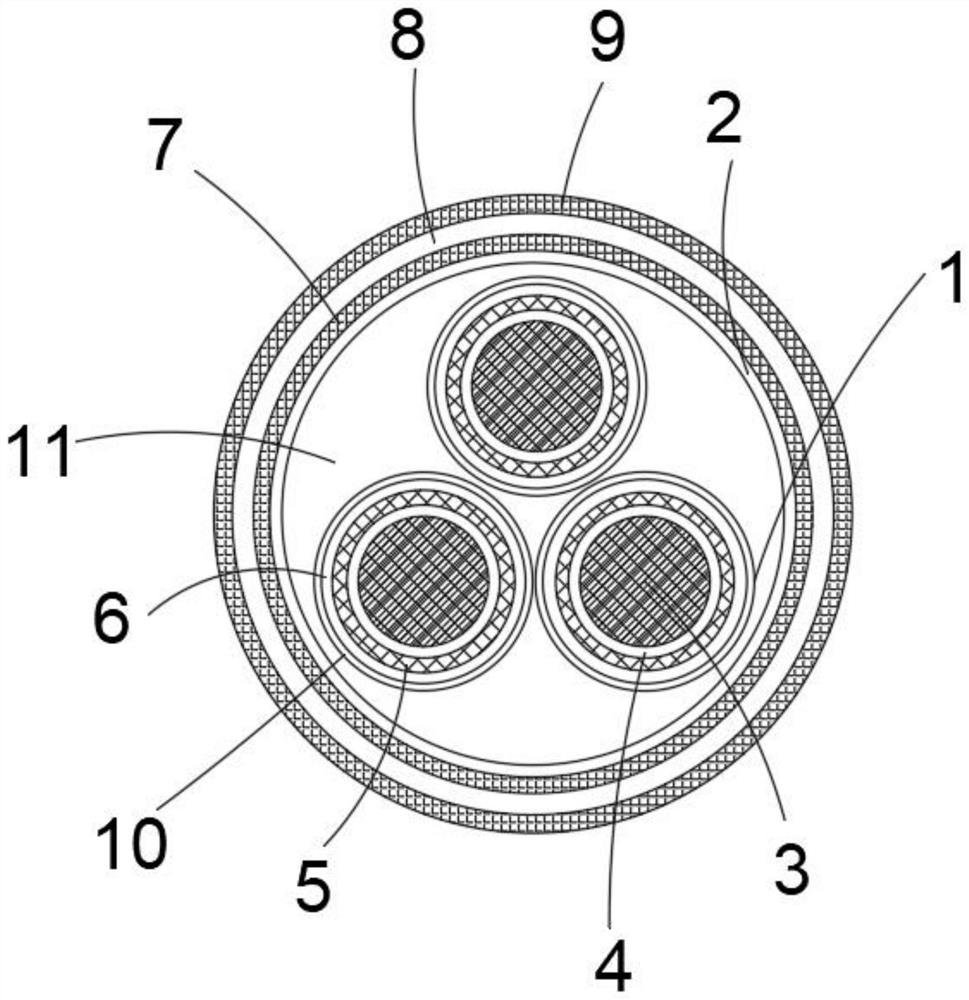

[0035] see figure 1 As shown, a cross-linked polyethylene insulated low-smoke halogen-free flame-retardant rodent-proof medium-voltage power cable includes a cable core 1 and a flame-retardant wrapping tape 2, and the cable core 1 is embedded in the flame-retardant wrapping tape 2 , the cable core 1 includes three conductor cores 3, each conductor core 3 includes a conductor and the conductor is sequentially covered with a conductor shielding layer 4, a cross-linked polyethylene insulating layer 5, an insulating shielding layer 6, The metal shielding layer 10, the gap between the flame-retardant wrapping tape 2 and the cable core 1 is the filling layer 11; the conductor shielding layer 4, the cross-linked polyethylene insulating layer 5, and the insulating shielding layer 6 are formed by three-layer co-extrusion;

[0036] The cable core 1 is wrapped with a flame-retardant wrapping tape 2, and an inner sheath 7 is extruded on the flame-retardant wrapping tape 2, and an armor 8 ...

Embodiment 2

[0053] see figure 1 As shown, a cross-linked polyethylene insulated low-smoke halogen-free flame-retardant rodent-proof medium-voltage power cable includes a cable core 1 and a flame-retardant wrapping tape 2, and the cable core 1 is embedded in the flame-retardant wrapping tape 2 , the cable core 1 includes three conductor cores 3, each conductor core 3 includes a conductor and the conductor is sequentially covered with a conductor shielding layer 4, a cross-linked polyethylene insulating layer 5, an insulating shielding layer 6, The metal shielding layer 10, the gap between the flame-retardant wrapping tape 2 and the cable core 1 is the filling layer 11; the conductor shielding layer 4, the cross-linked polyethylene insulating layer 5, and the insulating shielding layer 6 are formed by three-layer co-extrusion;

[0054] The cable core 1 is wrapped with a flame-retardant wrapping tape 2, and an inner sheath 7 is extruded on the flame-retardant wrapping tape 2, and an armor 8 ...

Embodiment 3

[0071] see figure 1 As shown, a cross-linked polyethylene insulated low-smoke halogen-free flame-retardant rodent-proof medium-voltage power cable includes a cable core 1 and a flame-retardant wrapping tape 2, and the cable core 1 is embedded in the flame-retardant wrapping tape 2 , the cable core 1 includes three conductor cores 3, each conductor core 3 includes a conductor and the conductor is sequentially covered with a conductor shielding layer 4, a cross-linked polyethylene insulating layer 5, an insulating shielding layer 6, The metal shielding layer 10, the gap between the flame-retardant wrapping tape 2 and the cable core 1 is the filling layer 11; the conductor shielding layer 4, the cross-linked polyethylene insulating layer 5, and the insulating shielding layer 6 are formed by three-layer co-extrusion;

[0072] The cable core 1 is wrapped with a flame-retardant wrapping tape 2, and an inner sheath 7 is extruded on the flame-retardant wrapping tape 2, and an armor 8 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com