Flow path switching valve

A flow path switching and valve shaft technology, applied in valve details, valve devices, multi-port valves, etc., to solve problems such as difficulty in managing the inclination of welded shells and complex shapes of shells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

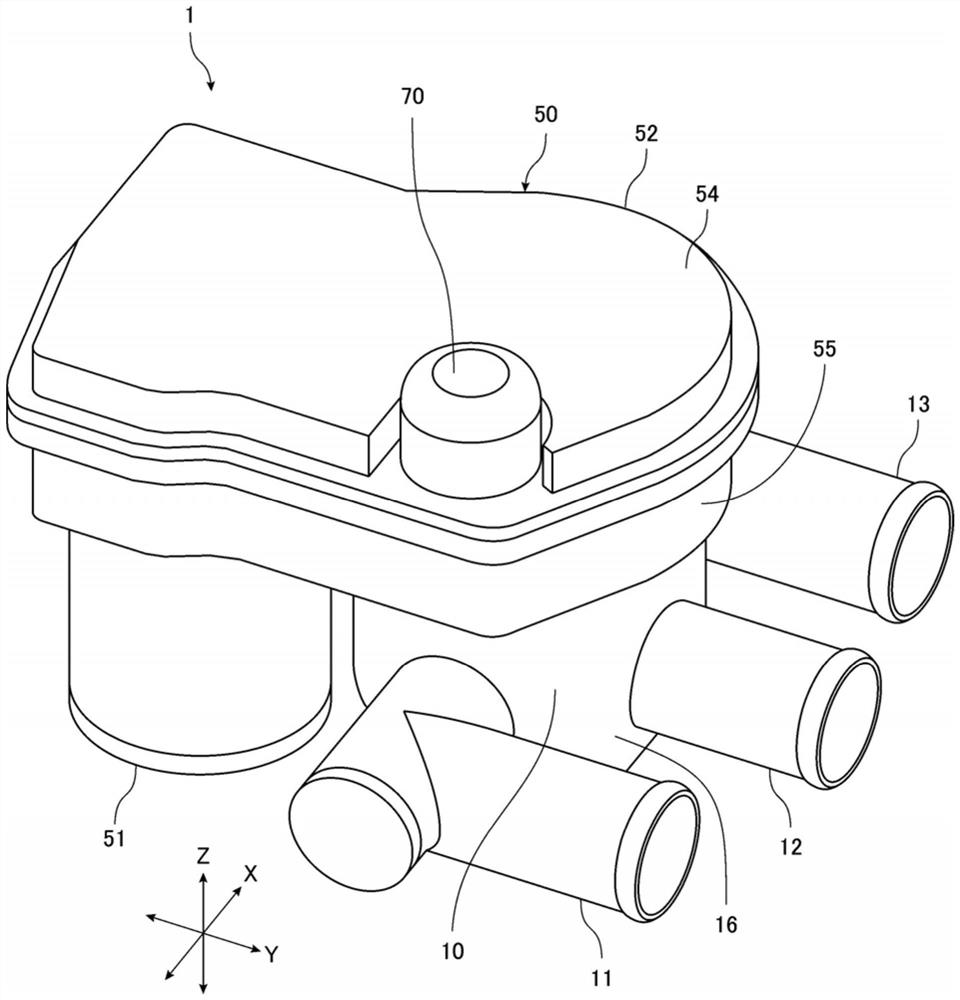

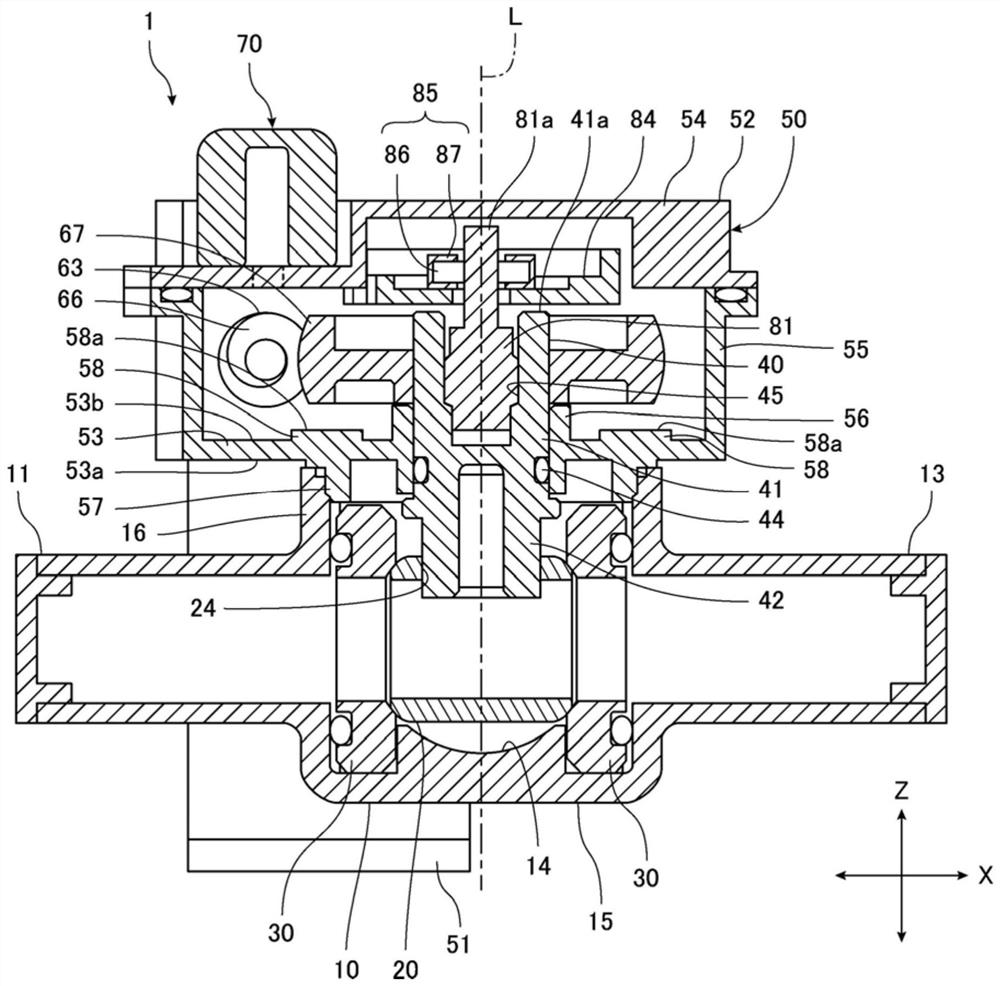

[0026] Below, refer to Figure 1 to Figure 8 A channel switching valve according to an embodiment of the present invention will be described.

[0027] figure 1 It is a perspective view of a channel switching valve according to an embodiment of the present invention. figure 2 yes figure 1 Left side view of the flow switching valve. image 3 yes figure 1 A cross-sectional view (longitudinal cross-sectional view) along the rotation axis of the ball valve core in the flow path switching valve. Figure 4 yes figure 1 The flow path switching valve has a top view of the valve body. exist Figure 4 In the valve chamber of the valve body, a ball valve core and a valve seat part are arranged. Figure 5 yes means figure 1 A plan view of the state where the upper wall portion of the gear box is removed of the channel switching valve of FIG. Figure 6 It is a plan view showing a state in which the rotation position detection unit is further removed. Figure 7 It is a plan view ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com