Grooving machine for underground grouting continuous wall construction and construction method

A slotting machine and grouting technology, which is applied in the direction of sheet pile wall, foundation structure engineering, earth mover/excavator, etc., can solve the problems of low construction efficiency and long construction period of diaphragm wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046]Contraction belowFigure 2-6Further detailed description of the present application.

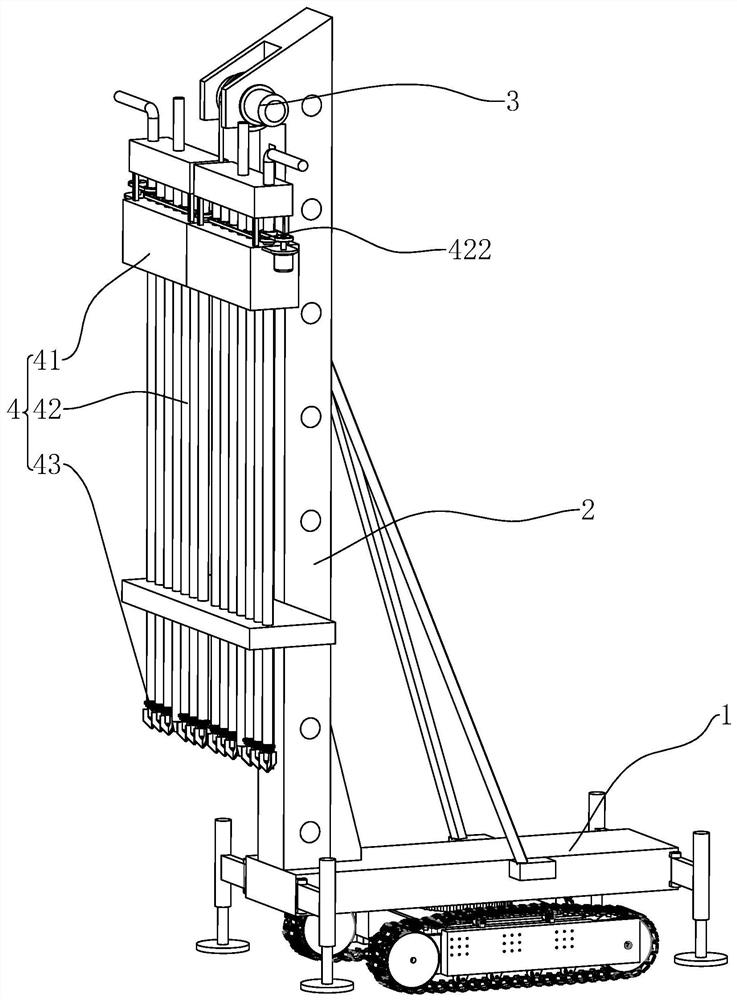

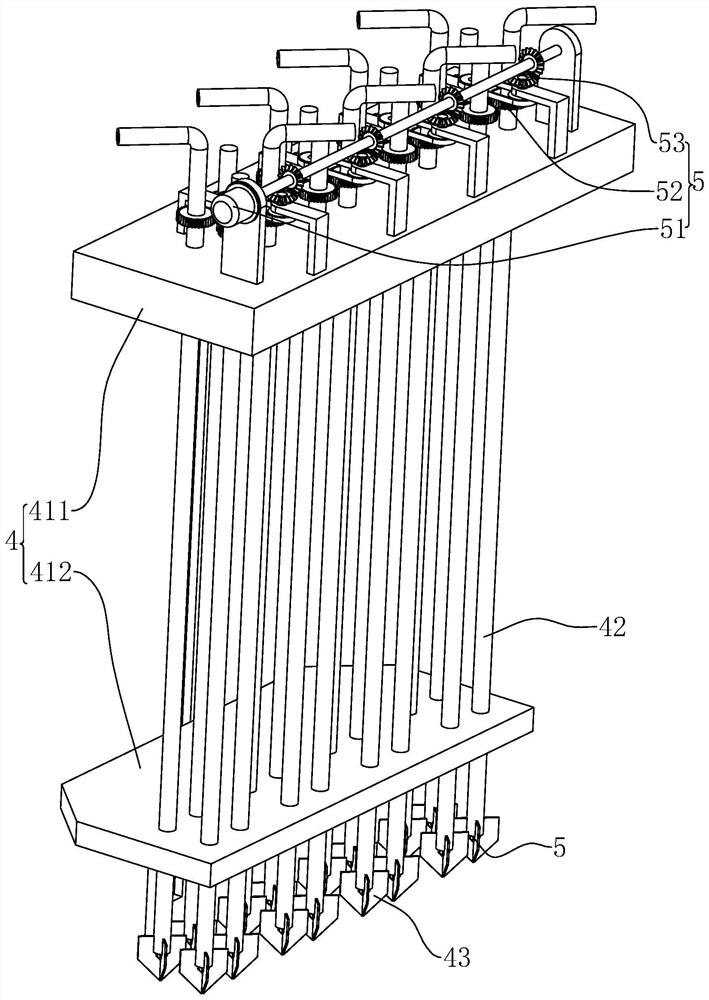

[0047]The present application discloses a slotting machine for underground grouting continuous wall construction. Referfigure 2 A slotting machine for construction of the underground grouting continuous wall includes a machine table 1, a guide bar 2, a lifting device 3, and a slotting device 4, and the machine 1 is disposed on the ground, the guide bar 2 vertical. The bottom end is fixed to the machine 2, and the lifting device 3 is disposed at the top end of the guide bar 2, and the slotting device 4 is located on one side of the lifting device 3, and the slotting device 4 is slidably connected to the machine 1. The device 4 includes a mounting frame 41, a drill pipe 42, and a drill bit 43, and the mounting frame 41 is slidably connected. The drill pipe 42 is vertically disposed, and the drill pipe 42 is aligned with two rows. The top end of the drill pipe 42 is rotated to the mounting frame 41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com