Bridge pier stud bent cap formwork system and construction method

A bridge and system technology, applied in the direction of bridges, bridge construction, bridge parts, etc., can solve problems such as low safety, many safety threats, materials, personnel, and large investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

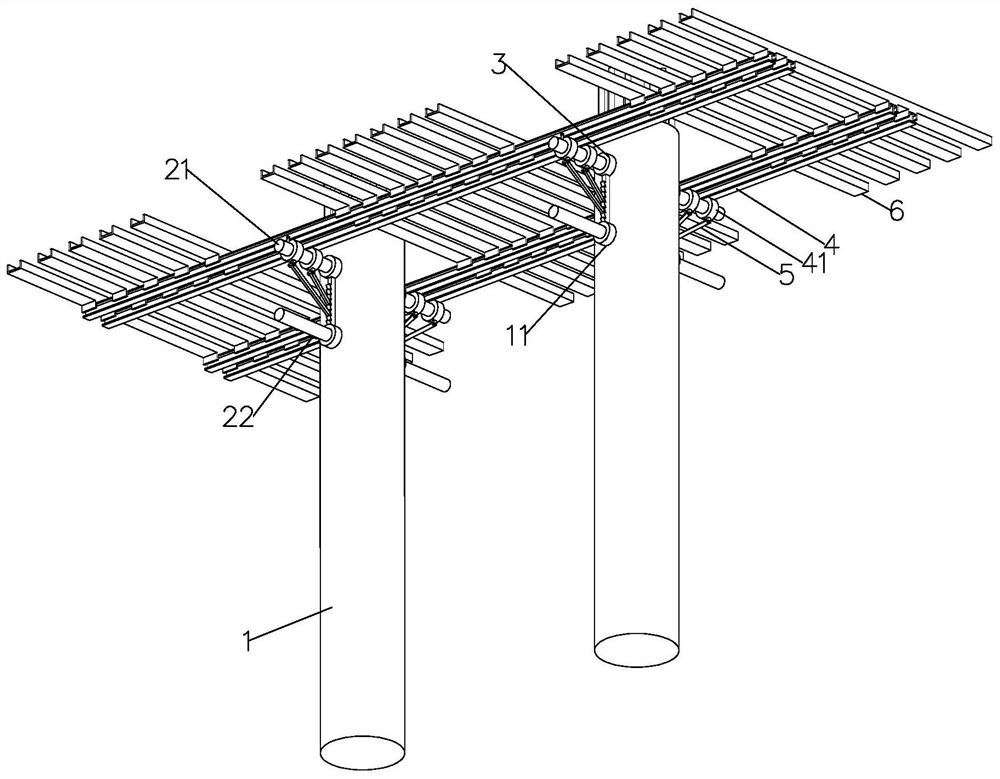

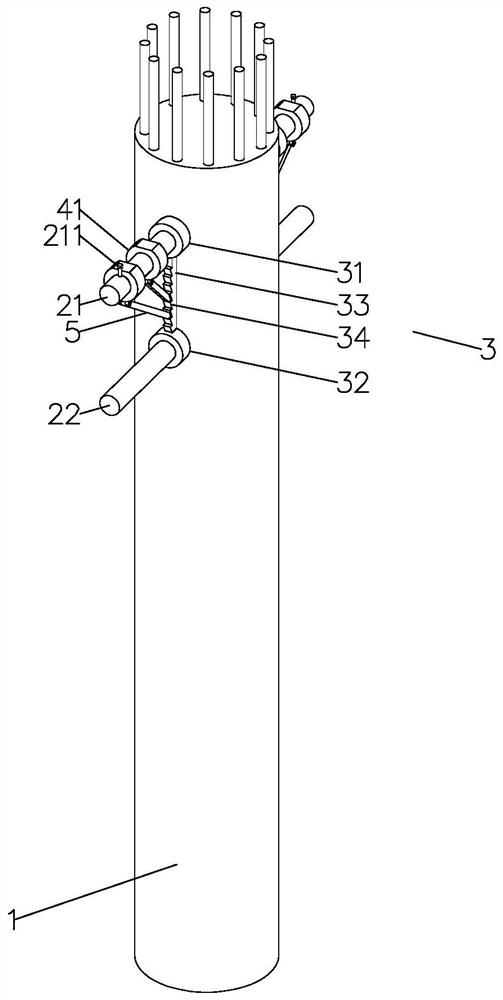

[0045] The following is attached Figure 1-4 The application is described in further detail.

[0046] The embodiment of the present application discloses a cover beam formwork support system based on bridge pier columns. refer to figure 1, the cover beam formwork system includes a pier column 1, and the pier column 1 is used as a supporting base. The bridge in this embodiment includes two pier columns 1, both of which are cylinders, and are set at the same height; the upper part of the pier column 1 is close to There are two perforations 11 at the position of the top. The axial directions of the two perforations 11 are parallel, and the upper and lower positions are opposite. They all pass through the central axis of the pier column 1. The axial direction is perpendicular to the plane where the axes of the two piers 1 are located.

[0047] A crossing strut is installed on the pier 1, and the crossing strut includes an upper strut 21 and a lower strut 22 with the same diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com