Medium-low fluorine slag system for electroslag remelting B-containing rotor steel ingot and use method

A technology of electroslag remelting and rotor steel, applied in the field of electroslag special metallurgy, which can solve the problems of high energy consumption, high fluorine slag volatilization pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] On the other hand, the present invention provides a method for preparing medium-low fluorine slag system, comprising the following steps:

[0057] Step 1: For commercially pure CaF 2 After high-temperature baking, it is ready for use;

[0058] Step 2: Use commercially pure CaF 2 , CaO, Al 2 o 3 , MgO, B 2 o 3 Prepare the slag system according to the mass percentage of the target slag system composition, and dry it for later use;

[0059] Step 3: heating and melting the melting point of the prepared slag system to obtain a molten slag product;

[0060] Step 4: Sprinkle water on the produced molten slag product, cool it, and break it into 3-6mm massive pre-melted slag for later use.

[0061] It should be noted that in the above step 1, considering factors such as the processing, production, and transportation of industrial raw materials, the industrially pure CaF2 is baked at a high temperature of 851-900°C for 2-4 hours for use in order to remove Moisture and imp...

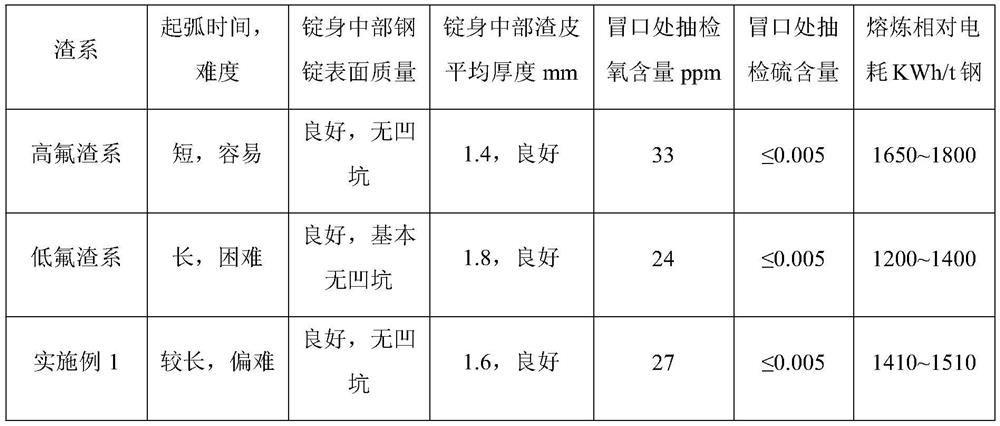

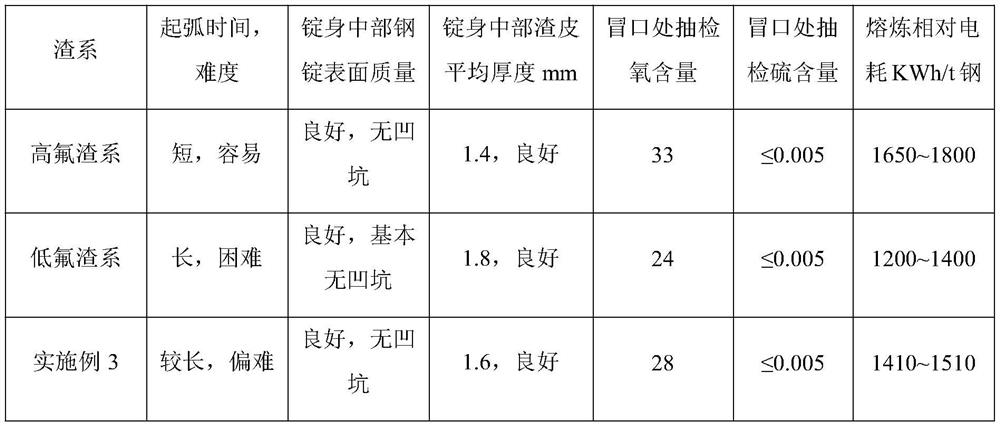

Embodiment 1

[0074] This embodiment provides a medium-low fluorine slag system for electroslag remelting of B-containing rotor steel ingots. The mass percentage of each component in the slag system is: CaF 2 : 33.20%, Al 2 o 3 : 43.79%, CaO: 19.50%, MgO: 3%, B 2 o 3 : 0.5%; the rest are impurities, among which SiO 2 The mass percentage content of ≤0.5%.

[0075] The basic physical properties of the slag system in this example are: melting point 1352°C, density range 2.70-2.71g / cm at 1700-1800°C 3 , the viscosity is 0.016~0.021Pa·s, and the conductivity range is 1.23~1.62S / cm.

[0076] The preparation method of the slag system comprises the steps of:

[0077] Step 1: Considering factors such as the processing, production, and transportation of industrial raw materials that may have a humid environment, the industrially pure CaF 2 Bake at 860°C for 3 hours and set aside for use to remove moisture and impurities;

[0078] Step 2: Use commercially pure CaF 2 , CaO, Al 2 o 3 , MgO, B...

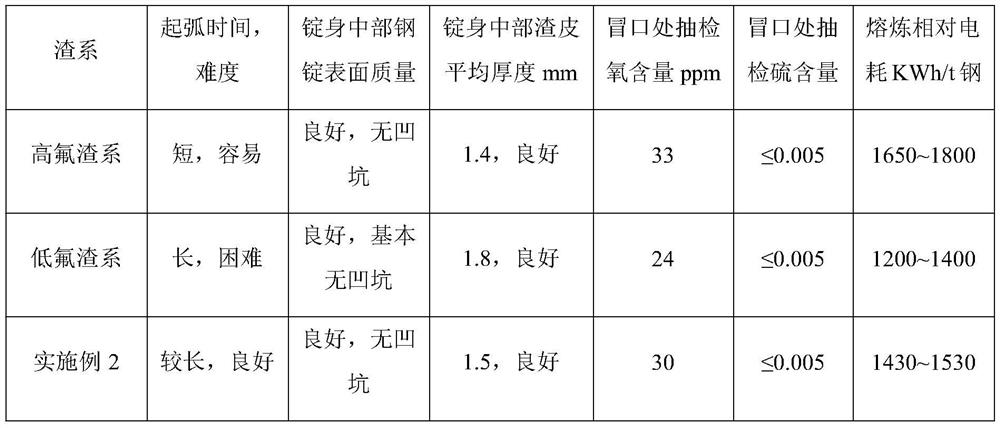

Embodiment 2

[0088] This embodiment provides a medium-low fluorine slag system for electroslag remelting of B-containing rotor steel ingots. The mass percentage of each component in the slag system is: CaF 2 : 39.30%, Al 2 o 3 : 34.02%, CaO: 22.68%, MgO: 3%, B 2 o 3 : 1%; the rest is impurities, among which SiO 2 The mass percentage content of ≤0.5%.

[0089] The basic physical properties of the slag system in this example are: melting point 1333°C, density range 2.67-2.69g / cm at 1700-1800°C 3 , the viscosity is 0.011~0.015Pa·s, and the conductivity range is 1.92~2.31S / cm.

[0090] The preparation method of the slag system comprises the steps of:

[0091] Step 1: Considering factors such as the processing, production, and transportation of industrial raw materials that may have a humid environment, the industrially pure CaF 2 Bake at 860°C for 3 hours and set aside for use to remove moisture and impurities;

[0092] Step 2: Use commercially pure CaF 2 , CaO, Al 2 o 3 , MgO, B 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com