Bottom air supply device of air supply stirrer

A technology of air supply device and agitator, applied in valve device, biochemical cleaning device, enzymology/microbiology device, etc., can solve the problems of fan burnout and trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

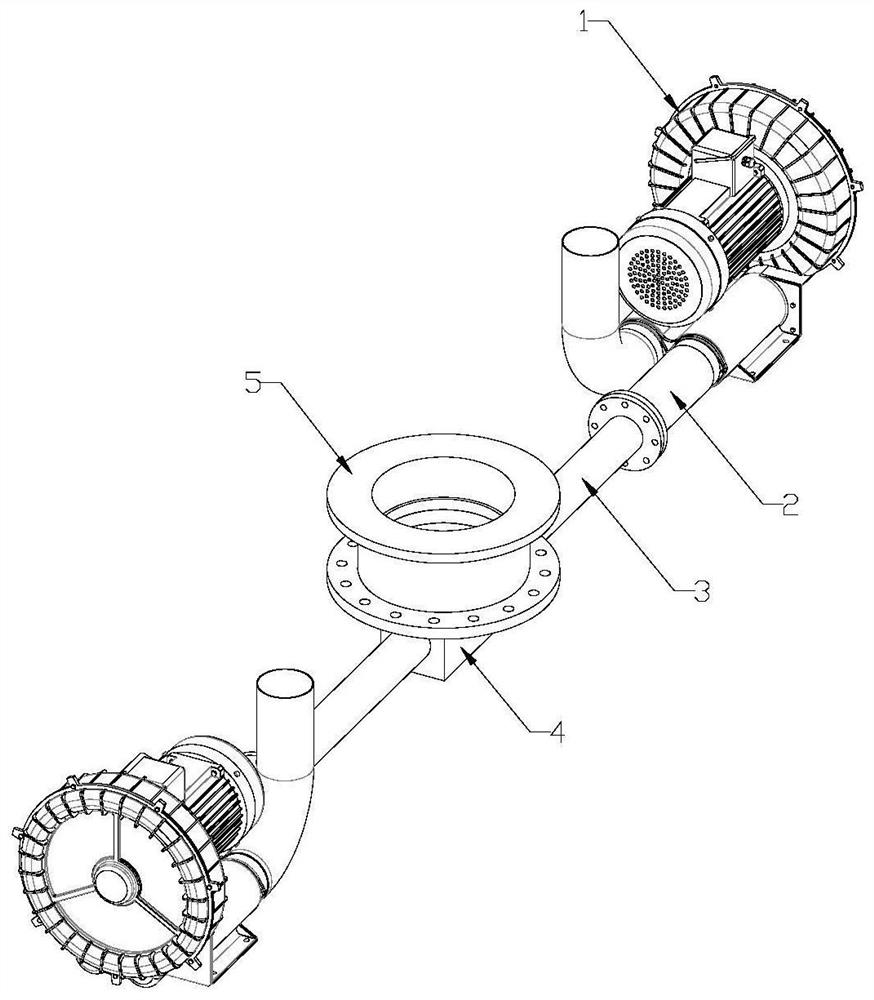

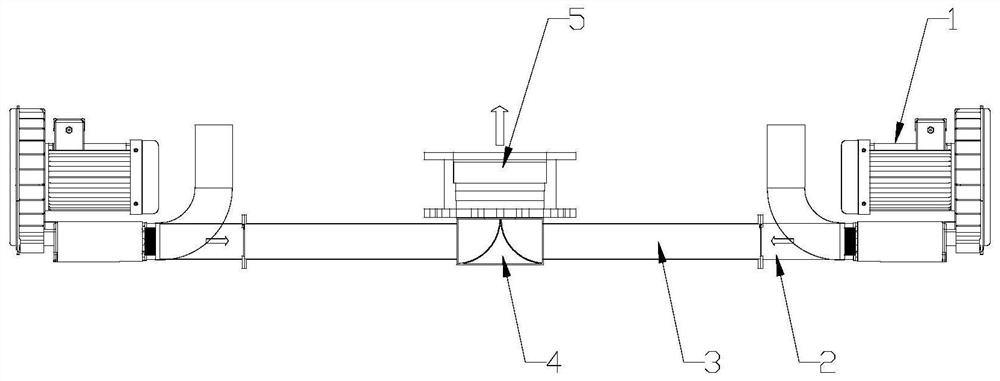

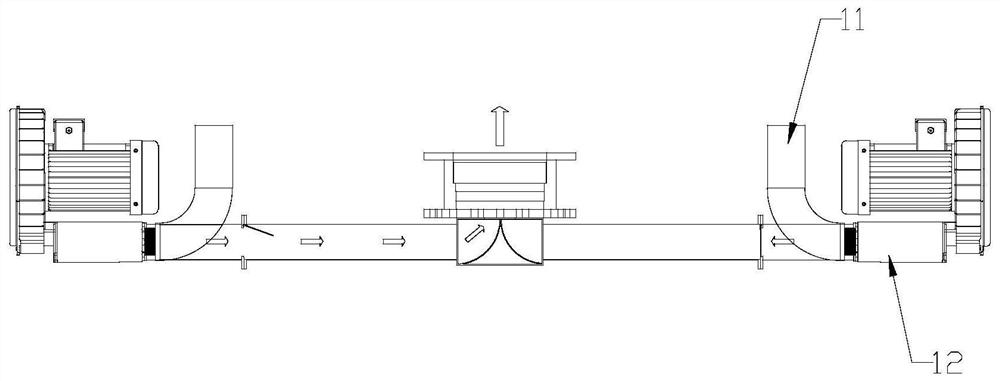

[0023] refer to Figure 1 to Figure 8 , a bottom air supply device of an air supply agitator of the present invention, comprising an oxygen fan 1, an air supply check valve 2, a ventilation duct 3, a diversion duct 4 and a bearing assembly 5, the outlet duct of the oxygen fan 1 12 and the ventilation duct 3 are arranged horizontally and are connected through the air supply check valve 2 to form an air supply unit. The air guide duct 4 is provided with an air separation plate 41 and separated to form several separate air guide and air supply units. Channel, the air inlet and the air outlet of the guide air supply channel are respectively located on the side wall and the top of the guide duct 4, and the free ends of the ventilation ducts 3 of several described air supply units are respectively arranged around the guide duct 4 and connected with the guide duct 4. The air inlets of the guide air supply channel are connected, and the bearing assembly 5 is fixed on the guide pipe 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com