Decoration and heat insulation integrated fabricated steel-bamboo combined wall

A prefabricated, wall technology, applied in the direction of building components, buildings, building structures, etc., can solve the problems of poor rigidity and bearing capacity, inconvenient dismantling, complicated installation, etc., to achieve large radius of gyration and moment of inertia, installation and Easy to disassemble later, excellent rigidity and bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in further detail below in conjunction with accompanying drawing:

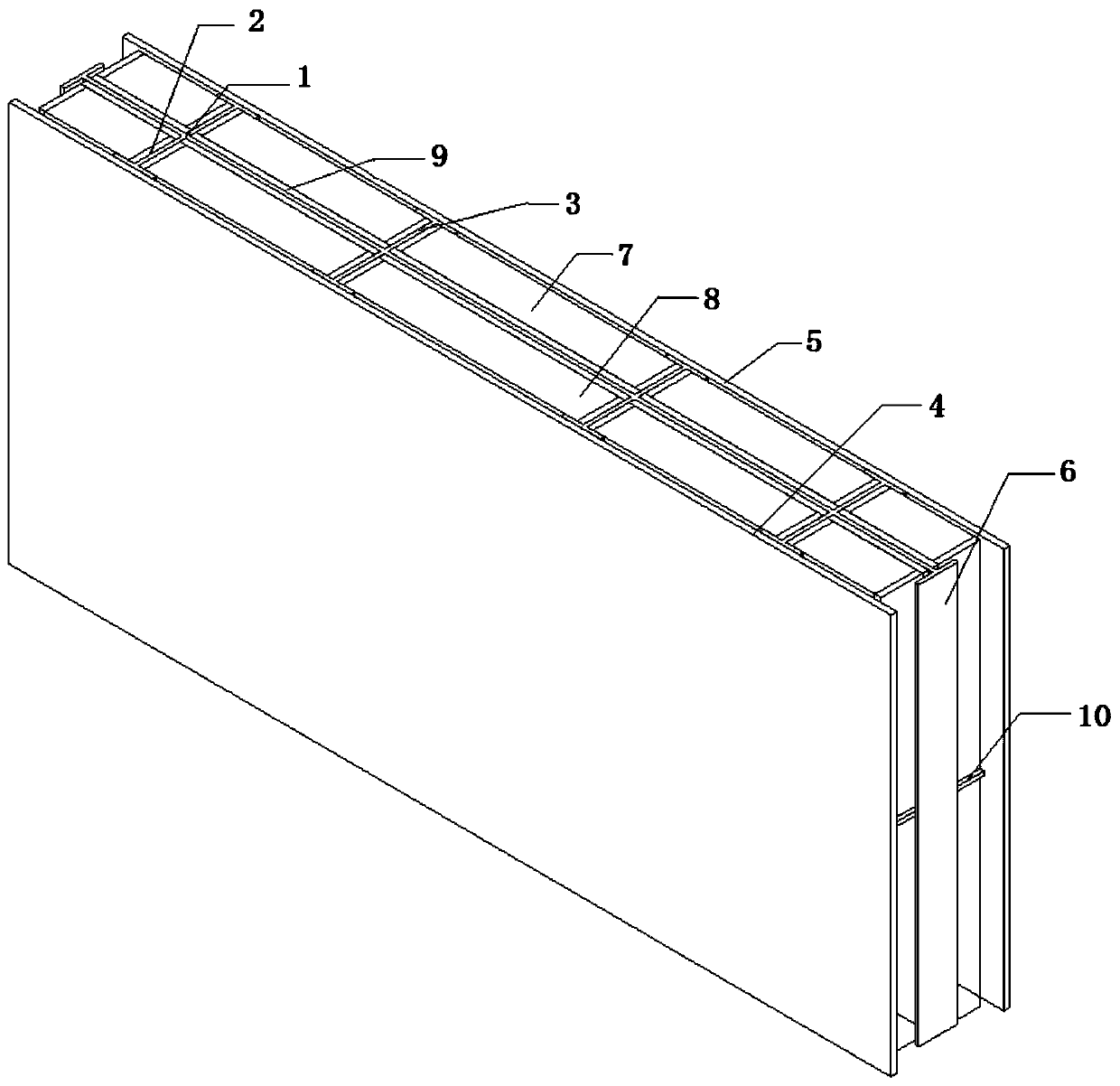

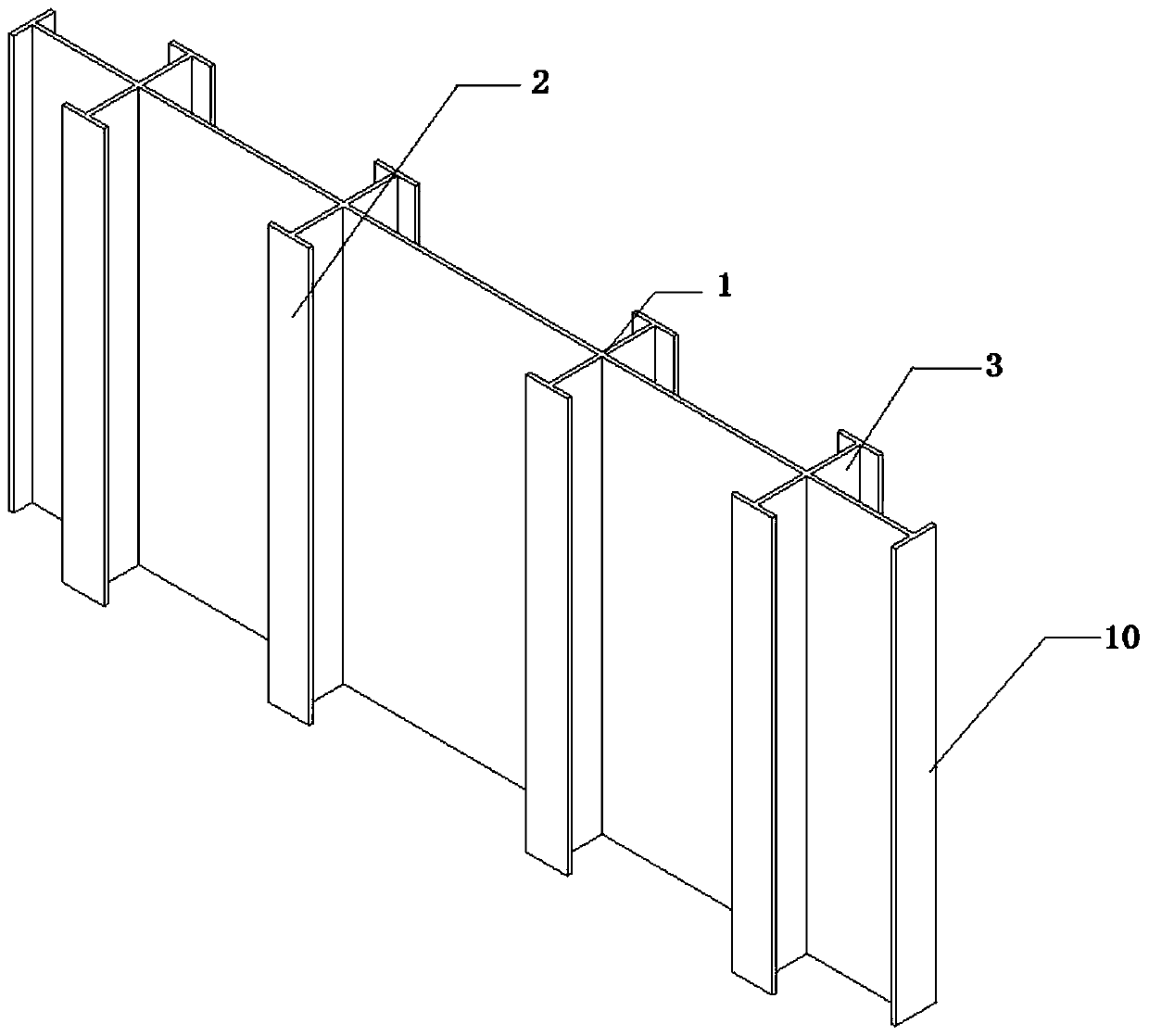

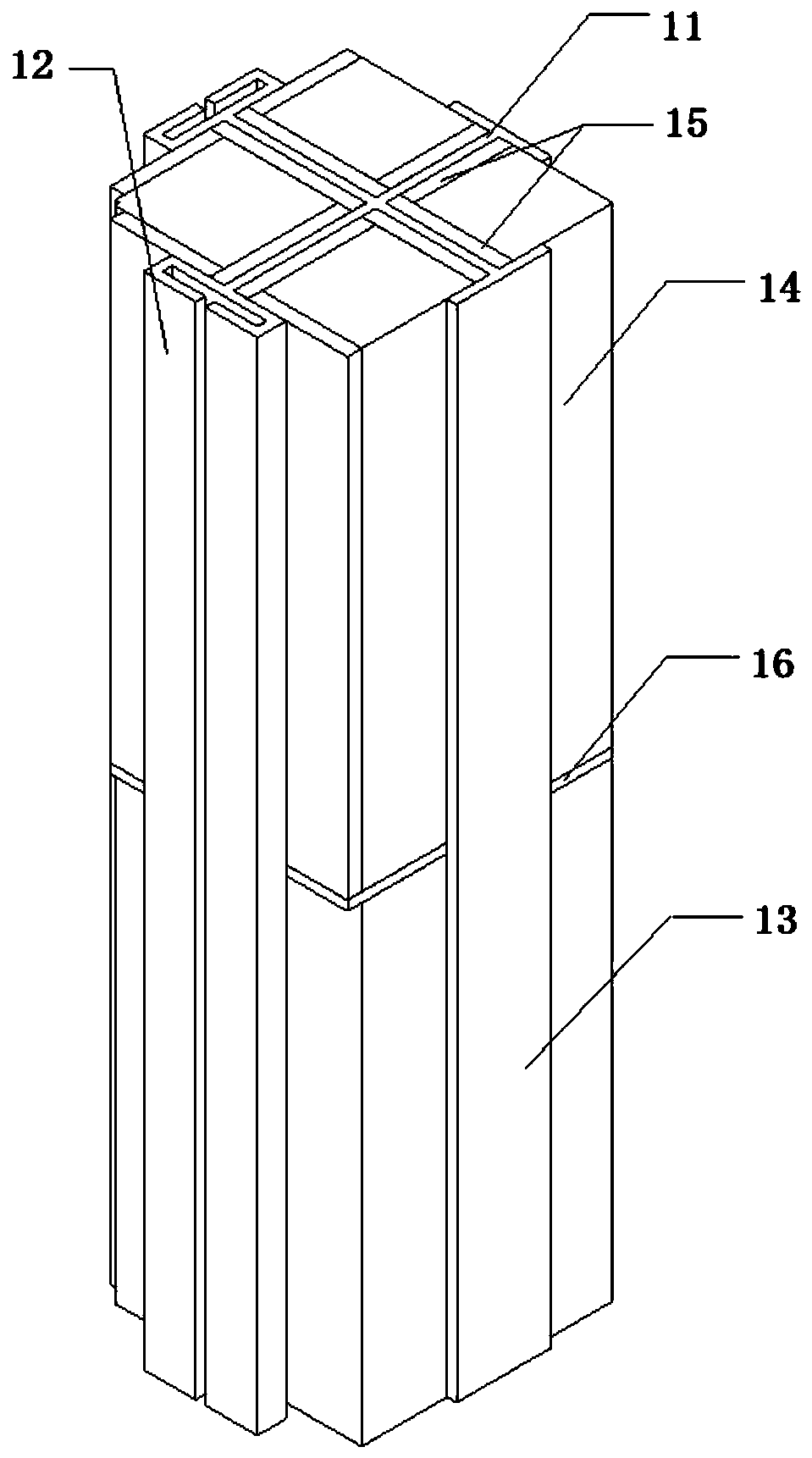

[0030] refer to figure 1 , figure 2 , Figure 4 and Figure 5 , the integrated decoration and heat preservation assembly steel-bamboo composite wall of the present invention includes a column connector and a wall; the wall includes a cold-formed thin-walled steel plate 1, and one side of the cold-formed thin-walled steel plate 1 A number of first T-shaped cold-formed thin-walled steel plates 2 are arranged on the top, and several second T-shaped cold-formed thin-walled steel plates 3 are arranged on the other side of the cold-formed thin-walled steel plate 1. The inner surface of the first bamboo plywood 4 It is connected with each first T-shaped cold-formed thin-walled steel 2, and the inner surface of the second bamboo plywood 5 is connected with each second T-shaped cold-formed thin-walled steel 3, and the first bamboo plywood 4 is connected with each first The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com