DDNP concentrated solid full automatic processing equipment and processing method

A technology for processing equipment and solids, which is applied in the field of DDNP concentrated solids automatic processing equipment and processing, can solve the problems of harsh operating environment, incomplete processing, and high processing costs, and achieve high automation, high space utilization, and The effect of simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

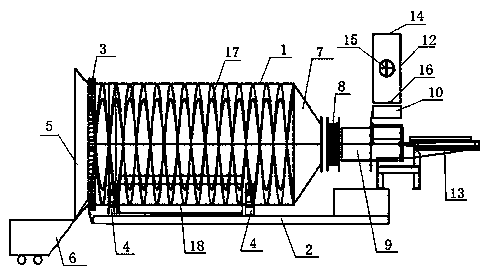

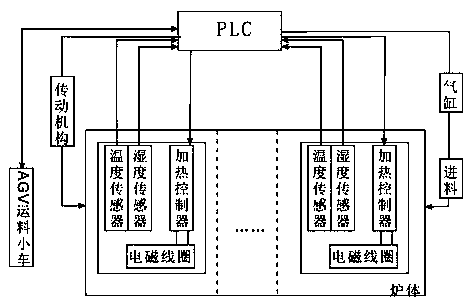

[0041] Embodiment 1: see Figure 1 to Figure 7 , a kind of DDNP concentrated solid automatic processing equipment, including a cylindrical furnace body 1 arranged horizontally, and also includes a PLC and a support platform 2, the furnace body 1 is located directly above the support platform 2, and one side of the furnace body 1 is set There is a transmission mechanism 3 for controlling the rotation of the furnace body 1 along the horizontal central axis of the furnace body 1, and a support 4 is provided at the bottom of the furnace body 1 close to both ends, and the support 4 is used to support the rotating furnace body 1;

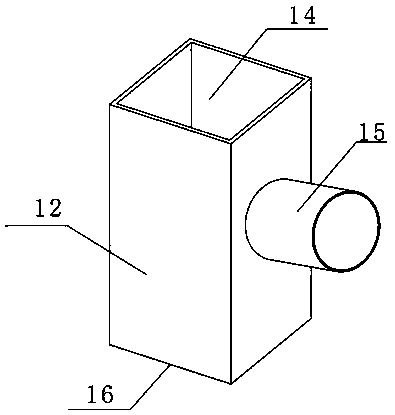

[0042] One end of the furnace body 1 is provided with a discharge port 5, and an AGV transport trolley 6 is provided at the discharge port 5, and a pair of interfaces 7 are provided at the other end of the furnace body 1, and a flange plate 19 is provided at the interface 7, The furnace body 1 is provided with a spiral blade 17 that transports the materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com