Method for treating high-salt and high-concentration active emerald blue textile wastewater through combination of UV/O3

A technology of active green orchid and textile wastewater, applied in water/sludge/sewage treatment, water/sewage multi-stage treatment, oxidized water/sewage treatment, etc., can solve problems such as poor treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A columnar processor with a UV lamp in the center, with a structure such as figure 1 As shown, a cylindrical reactor 1 is included, the bottom of the cylindrical reactor 1 is provided with a microporous aeration head 3, the aeration head 3 is connected with an external ozone generator, and the upper part of the reactor is provided with a water outlet and an air outlet 5 , the lower part is provided with a water inlet (not shown in the figure), and a UV lamp 2 is provided at the center of the reactor.

[0049] One UV lamp 2 is set at the center of the reactor at a 360° radiation angle, and the distance between the bottom of the UV lamp 2 and the aeration head 3 is 7 cm. The bottom end of the reactor is provided with a base, and the center of the base is provided with a circular hole that penetrates up and down. The aerator head is fixed on the upper part of the circular hole. The ozone inlet pipe 4 of the ozone generator penetrates into the circular hole and communicate...

Embodiment 2

[0051] A UV / O 3 The method for joint treatment of high-salt high-concentration active emerald blue textile wastewater, the method adopts the processor described in embodiment 1 to carry out, and the steps are as follows:

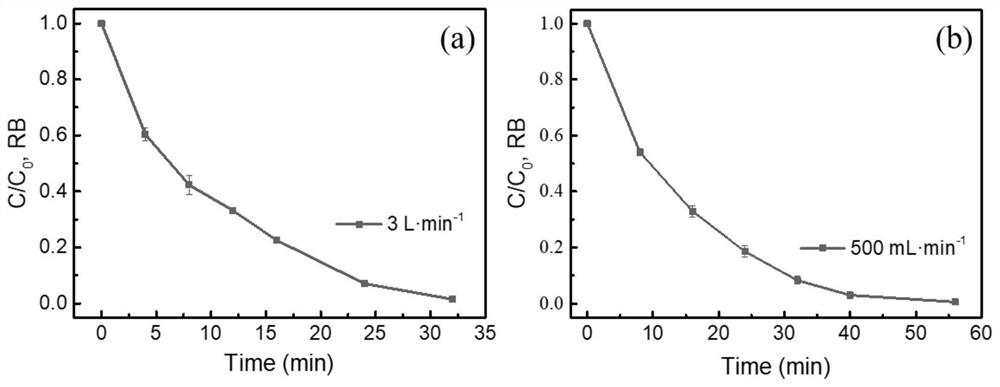

[0052] Adjust the pH of the active Cuilan K-GL textile wastewater to 10, pass ozone into the active Cuilan K-GL textile wastewater, and control the ventilation rate of ozone at 500mL min -1 , Turn on the UV lamp to preheat for 5 minutes, the wavelength of UV light is 254nm, use the UV lamp to irradiate the wastewater, and use ozone and UV to treat the active Cuilan K-GL textile wastewater for 56 minutes at the same time to achieve efficient degradation of organic pollutants.

experiment example 1

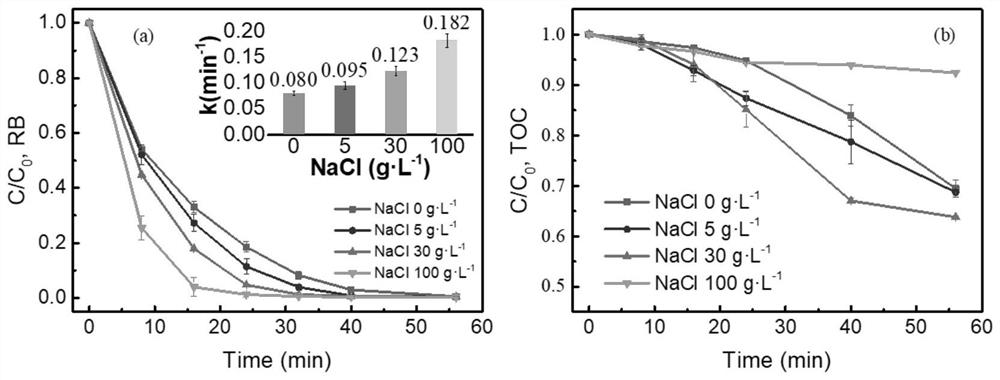

[0056] Change the amount of ozone in the treatment method of Example 2, and the effect of different ozone amounts on the ozone oxidation degradation activity Cuilan K-GL textile wastewater is as follows: figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com