Soft foam plastic product preparation equipment

A technology for flexible foam plastics and products, which is applied in the field of foam plastics and can solve problems such as partition breakage and irregular cutting of flexible foam plastics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

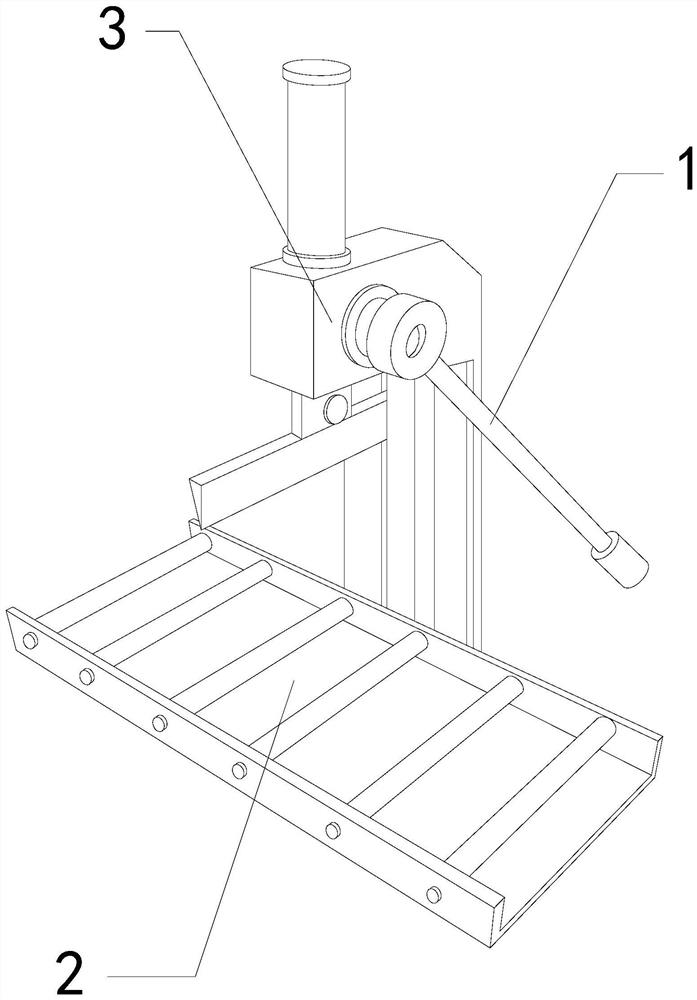

[0026] For example figure 1 -example Figure 5 Shown:

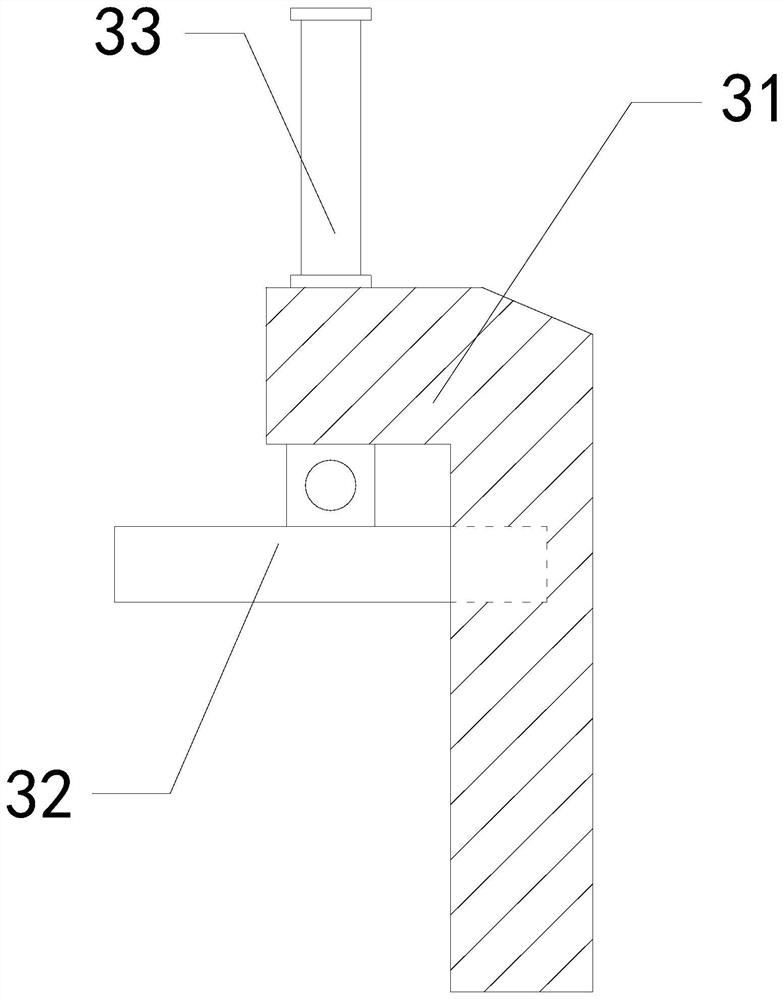

[0027] The invention provides a flexible foam plastic product preparation equipment, the structure of which includes a handle 1, a transfer table 2, and a cutting table 3, the handle 1 is movably engaged with the side of the cutting table 3, and the cutting table 3 is connected to the transfer table The rear end of 2 is welded; the cutting table 3 includes a support frame 31, a cutter 32, and a lower push rod 33, the cutter 32 is installed on the inner side of the support frame 31, and the lower push rod 33 is embedded in the support The upper end position of frame 31.

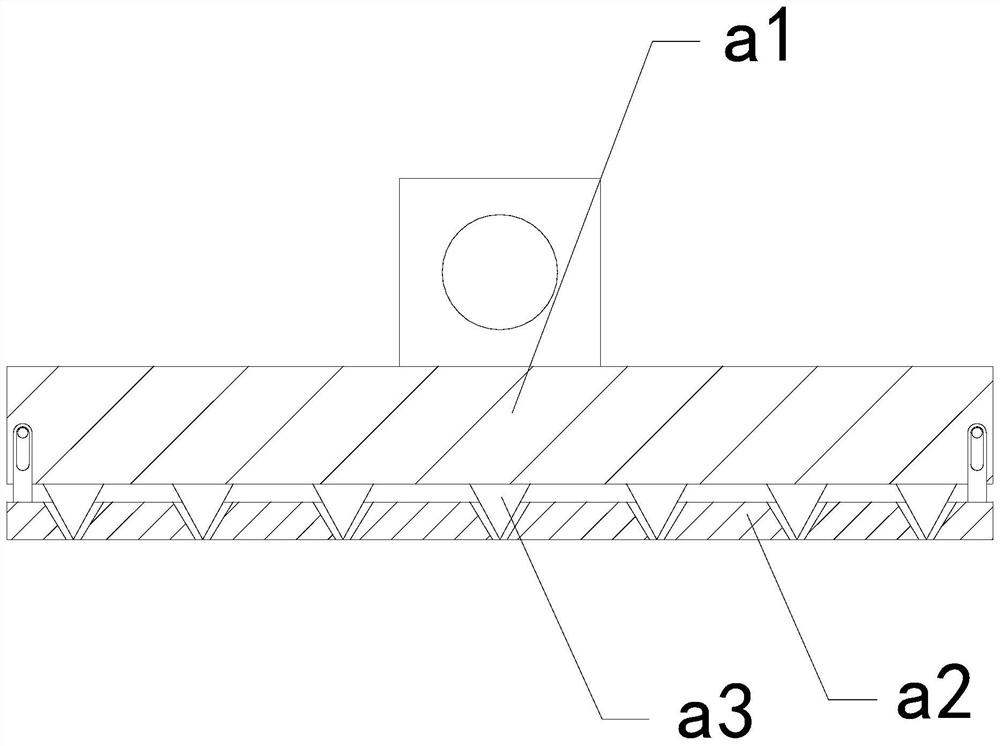

[0028] Wherein, the cutter 32 includes an upper connecting plate a1, a resisting plate a2, and a sawtooth a3, the resisting plate a2 is movably engaged with the bottom of the upper connecting plate a1, and the sawtooth a3 is embedded and fixed at the bottom of the upper connecting plate a1 , there are seven sawtooth a3, which are evenly distributed in ...

Embodiment 2

[0034] For example Figure 6 -example Figure 8 Shown:

[0035] Wherein, the collision plate a2 includes a transition rod c1, a bouncing ball c2, an inscribed cavity c3, and a cutter body c4, the transition rod c1 is embedded in the upper end of the cutter body c4, and the bouncing ball c2 is installed in the inscribed cavity The internal position of c3, the inscribed cavity c3 and the cutter body c4 are an integrated structure, and the bouncing ball c2 is made of alloy steel with high density. The inner wall of the connection cavity c3 is impacted, so that vibration can be generated to shake off the foamed plastic particles.

[0036]Wherein, the bouncing ball c2 includes a re-impact block c21, an elastic ring c22, an inner solid block c23, and a vibration-receiving ring c24. The re-impact block c21 is connected to the outside of the elastic ring c22, and the elastic ring c22 is embedded in the The position of the outer surface of the inner solid block c23. The inner solid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com