Tundish preheating automatic control method based on continuous temperature measurement

A technology of tundish and preheating time, applied in the direction of manufacturing tools, casting molten material containers, casting equipment, etc., can solve the problems of development and publication, no process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

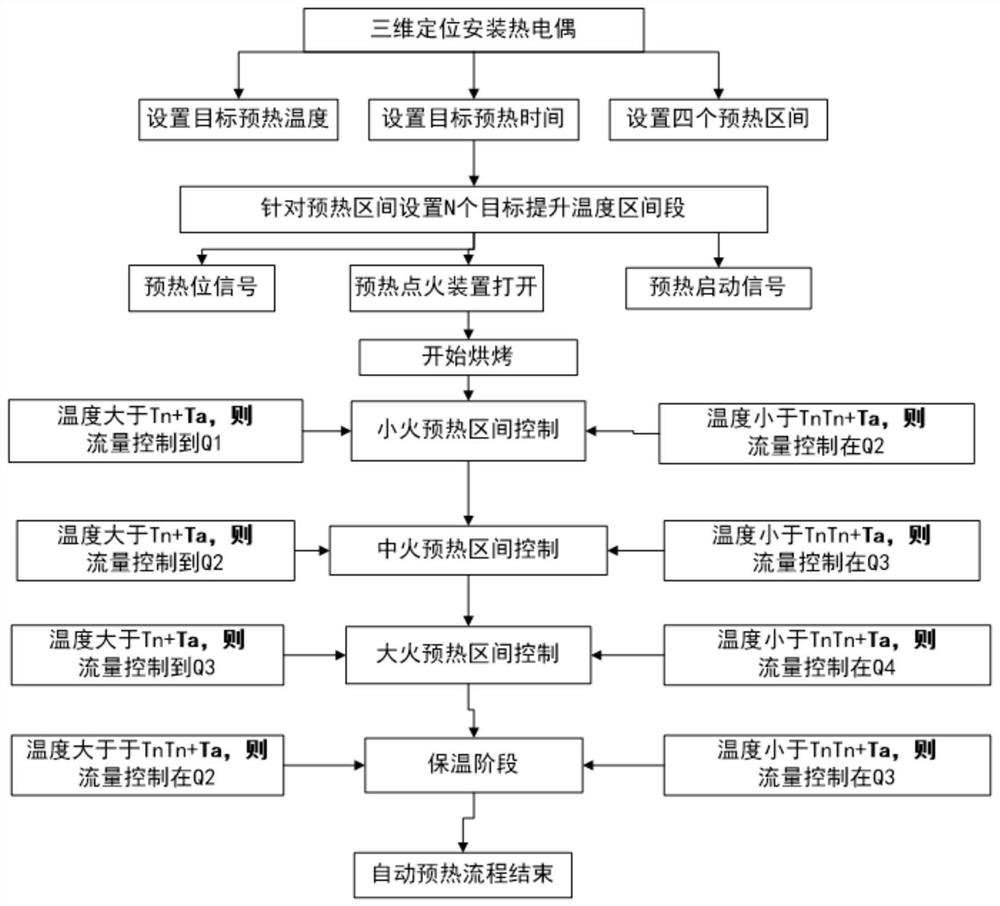

[0029] Embodiment 1: see figure 1 , an automatic control method for tundish preheating based on continuous temperature measurement, the control method comprising the following steps:

[0030] Step 1. The three-dimensional positioning method installs the continuous temperature measurement coupler in the tundish;

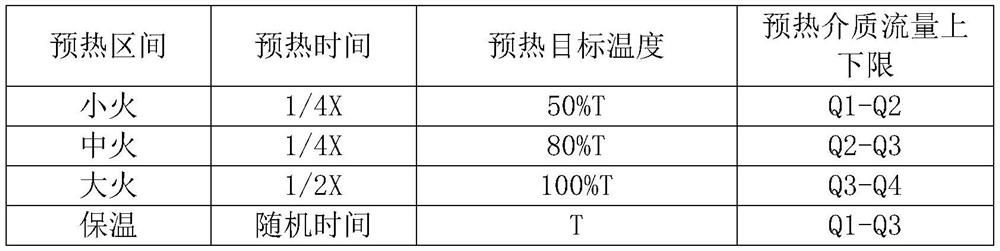

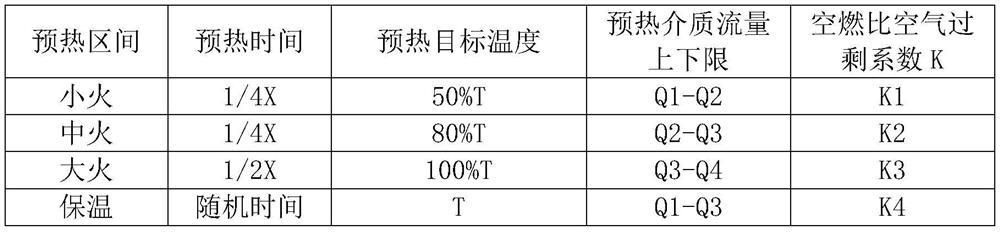

[0031] Step 2. According to the target temperature of the tundish, the preheating temperature (1100°C-1300°C) and the tundish preheating time are divided into four preheating intervals: low fire, medium fire, high fire and heat preservation. According to the temperature rise rate of the refractory material in the tundish, set the segmental target temperature range, and set the target range temperature and the air excess coefficient of the air-fuel ratio for the corresponding preheating range;

[0032] Step 3, collecting continuous casting tundish position signal, preheat ignition device signal and preheat start signal;

[0033] Step 4. When the tundish position signal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com