Pipeline pre-purging system and method suitable for supercritical carbon dioxide Brayton cycle

A Brayton cycle, carbon dioxide technology, applied in piping systems, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of uncertain safe and stable operation, inability to discharge water, and increasing the cost and complexity of system piping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in further detail below in conjunction with embodiment.

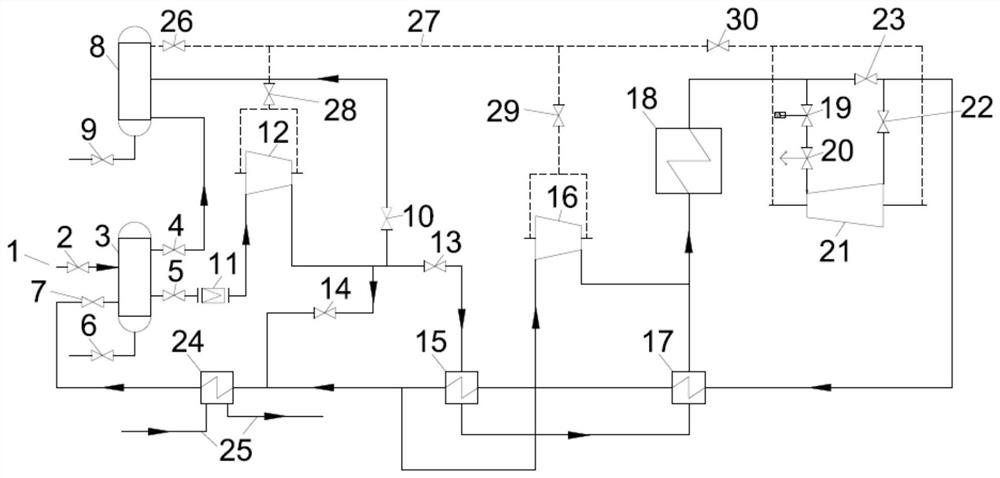

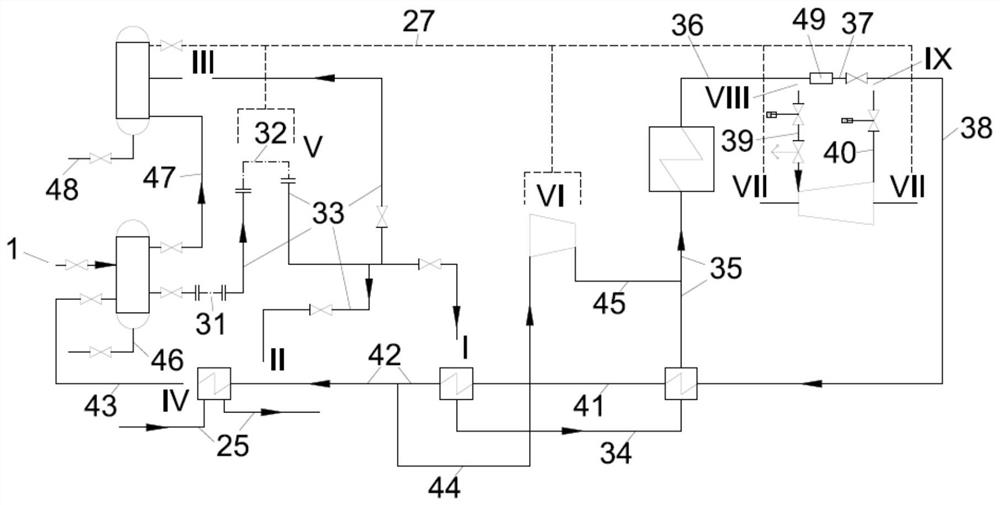

[0026] like figure 1 figure 2 Shown: a pipeline pre-purging system suitable for supercritical carbon dioxide Brayton cycle, including a CO2 storage tank set in the pipeline of supercritical carbon dioxide Brayton cycle, the CO2 storage tank is filled with a certain pressure CO2 working medium, the CO2 working medium in the CO2 storage tank purges the low-temperature pipeline, and the pipeline not directly connected to the CO2 storage tank uses the compressor in the system to establish a working medium circulation, passing through the filter 11 and The particle collector 49 filters the impurities in the pipeline.

[0027]The filter 11 of the compressor inlet in the pipeline of the supercritical carbon dioxide Brayton cycle is replaced with a temporary pipe 31, and the compressor 12 is replaced with a temporary pipe 32 of the compressor section, and the outlet pipe of the compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com