Preparation method of anhydrous magnesium sulfate drying agent

A technology of anhydrous magnesium sulfate and desiccant, applied in grain processing, etc., can solve the problems of low equipment processing efficiency, affecting the normal use of equipment, and low quality of anhydrous magnesium sulfate powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

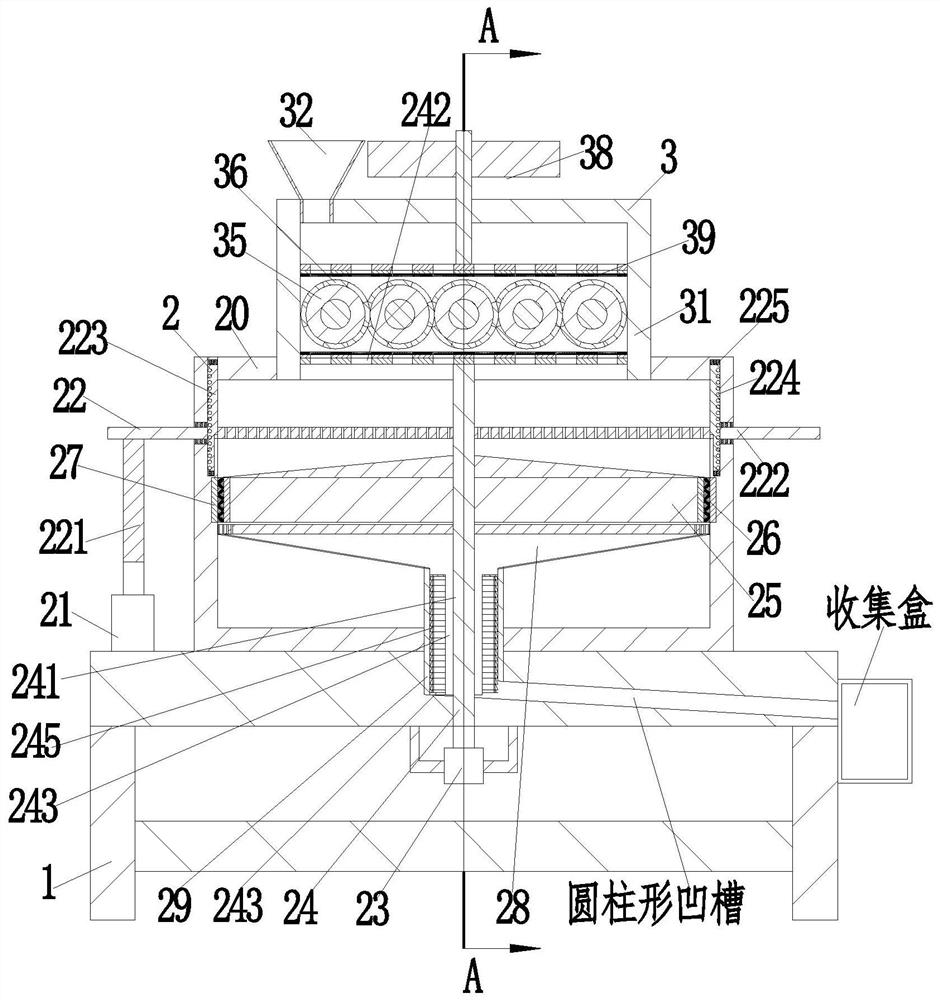

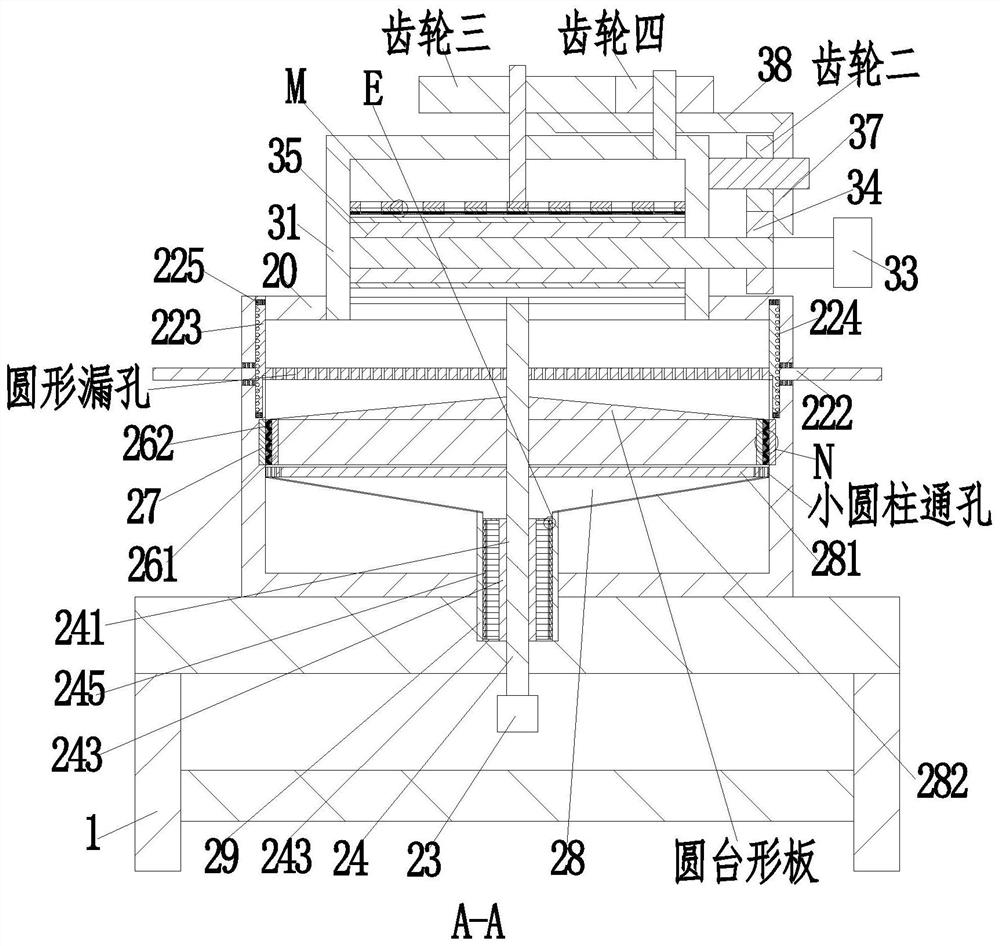

[0035] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 6 , to further elaborate the present invention.

[0036] A method for preparing anhydrous magnesium sulfate desiccant, which uses an anhydrous magnesium sulfate desiccant preparation equipment, the anhydrous magnesium sulfate desiccant preparation equipment includes workbench 1, processing device one 2 and processing device two 3, using The specific method when the above-mentioned anhydrous magnesium sulfate desiccant preparation equipment prepares anhydrous magnesium sulfate desiccant is as follows:

[0037] S1, feeding raw materials: passing the anhydrous magnesium sulfate block into the square cylinder 31 through the feeding funnel 32;

[0038] S2. Grinding raw materials: Motor 2 33 drives the screw rod 35 to rotate, thereby crushing the anhydrous magnesium sulfate block. Magnesium sulfate par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com