Jet loop reactor for preparing ethylene through oxidative coupling of methane

A loop reactor, oxidative coupling technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low ethylene yield, serious back-mixing, and uneven temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

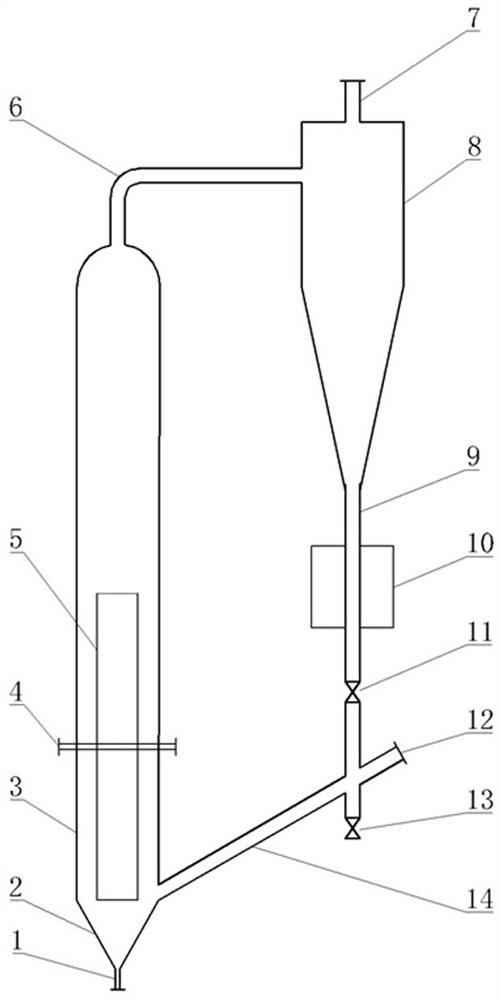

[0027]An injection annular reactor for methane oxidation occlusion, is divided into a conical bottom region, a circulation region, a gas-solid separation zone, a cyclone separation zone, and a return zone. The tapered bottom region includes nozzle 1 and cone bottom 2; the circulation region includes a lower space, a gas distributor 4, and a guide cylinder 5 in the casing 3; the gas-solid separation zone includes the upper space of the housing 3; the cyclone separation zone includes a cyclone separation A device 8; the return zone comprises the leg 9, the heat exchanger 10, the retainer 11, the secondary wind inlet 12, the discharge valve 13, and the return tube 14.

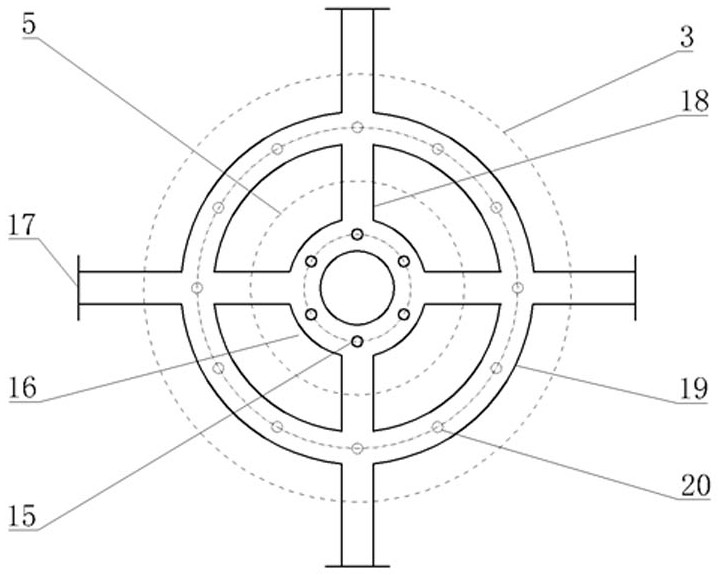

[0028]Such asfigure 1 As shown, the nozzle 1 is located at the bottom of the conical bottom 2, and the tapered bottom 2 is located at the bottom of the housing 3, and the guide cylinder 5 is placed in the lower portion of the housing 3, and the gas distributor 4 is transverse to the housing 3 and its vertical center line a...

Embodiment 2

[0032]Unlike Example 1, the catalyst has an average particle diameter of 100 μm, and the reaction temperature is 850 ° C, at an attenuated operation, the gas component of the nozzle is mainly methane, and the gas component of the gas distributor and the secondary venting air is mainly Oxygen and nitrogen, volume vacuum rate is 8000 h-1, Methane: oxygen: Nitrogen molar ratio is 3: 1: 1, the methane conversion is 47%, and the ethylene yield is 31%.

Embodiment 3

[0034]Unlike Example 1, the average particle diameter of the catalyst is 150 μm, the reaction temperature is 800 ° C, the operating pressure is 5 bar, and the gas components passing through the nozzle are mainly methane and oxygen, through the gas distributor and the secondary venting air. The gas component is mainly oxygen and nitrogen, the volume vacant is 6000 h-1, Methane: oxygen: Nitrogen molar ratio is 3: 1: 1, the methane conversion is 46%, and the ethylene yield is 27%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com