Method for measuring normal meshing tooth profile of involute spiral cylindrical gear

A technology of cylindrical gears and measuring methods, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve the problem that the real information of gear transmission quality and processing quality cannot be effectively reflected, and the measuring instrument has no normal meshing teeth Shape measurement function and other issues to achieve the effect of ensuring high precision, high efficiency, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047]The present invention will be further described in connection with the accompanying drawings and specific embodiments. However, it should not be understood that the scope of the above-described above-described above-described embodiments is limited to the following embodiments, and the techniques achieved by the present invention are within the scope of the present invention.

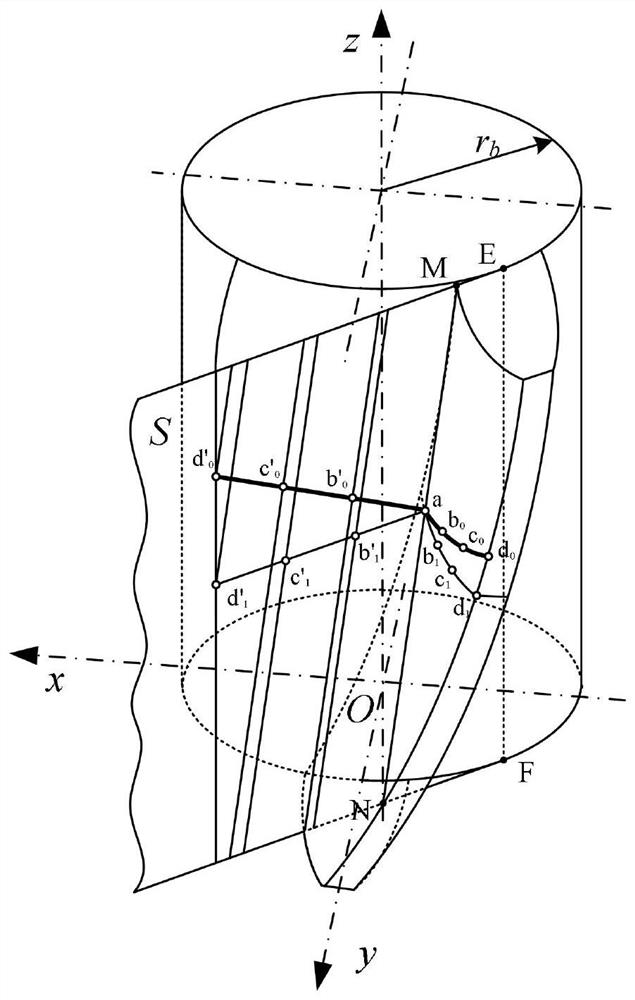

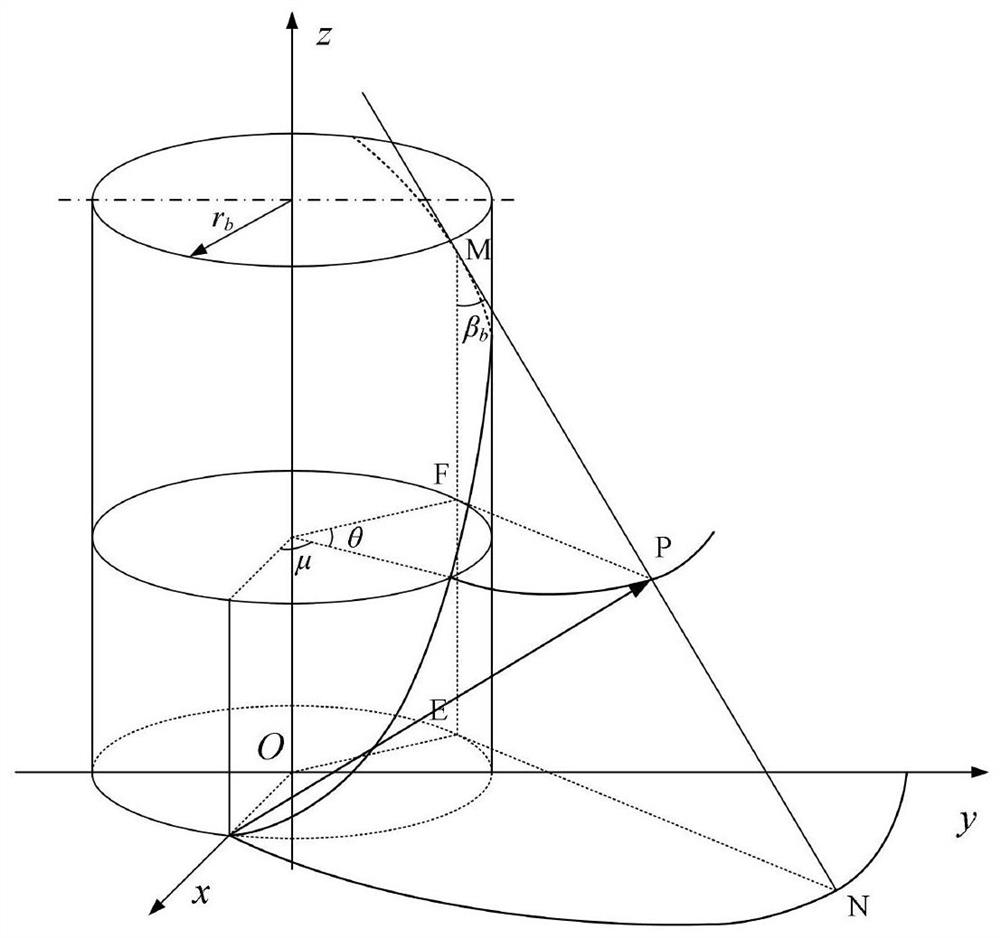

[0048]Such asfigure 2 As shown, the coordinate system δ (OX, Y, Z) is established, with δ as the coordinate system name, O is a symmetrical center of the gear, X, Y, and Z is three coordinate shafts, Z-axis, respectively Annlament with the axis of the measured gear, RbThe radius of the base cylinder of the gear is measured. The plane S is a cutting surface of the gear base cylinder, which is related to the straight line EF with the gear base cylinder, and intersecting the teamed gear surface of the gear to the straight line MN. The straight line Mn is a busbar that is formed by the gear surface of the gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com