Self-supporting fracturing fluid system for modifying unconventional reservoir fracture network segment

A self-supporting, fracturing fluid technology, applied in the direction of production fluid, drilling composition, wellbore/well components, etc., can solve the problems of limited increase in production capacity, difficult access of proppant, poor sand-carrying ability of slick water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose, technical solution and advantages of the present disclosure clearer, the implementation manners of the present disclosure will be further described in detail below in conjunction with the accompanying drawings.

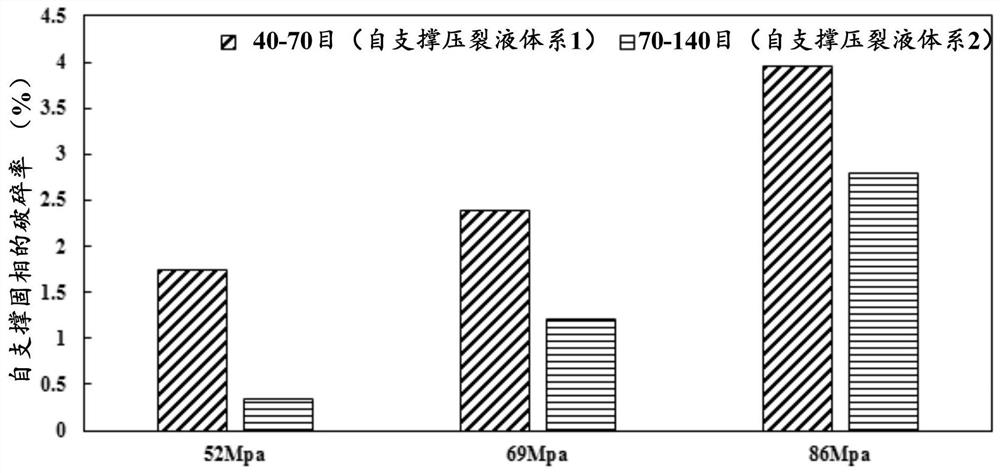

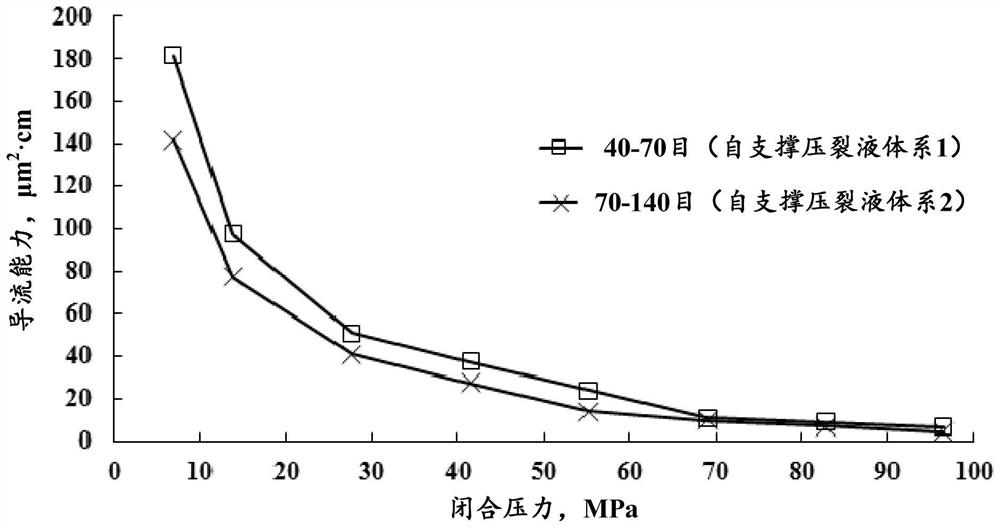

[0030] An embodiment of the present disclosure provides a self-supporting fracturing fluid system for fracture network segment reconstruction of unconventional reservoirs. The self-supporting fracturing fluid system includes a fracture network segment self-supporting fracturing fluid and a fracture network segment Channel fracturing fluid.

[0031] The self-supporting fracturing fluid in the fracture network section includes the following components: 10-40 parts of polyphenylene ether, 10-20 parts of dicumyl peroxide, 10-50 parts of triallyl isocyanurate, 40-90 parts of styrene, 1-10 parts of surfactant, 50-500 parts of solvent.

[0032] The channel fracturing fluid in the fracture network section includes the following components...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com