Iron tailing unfired ceramsite and preparation method thereof

A technology of iron tailings and ceramsite, which is applied in the field of iron tailings unburned ceramsite and its preparation, can solve problems such as energy waste, environmental pollution, and increased production costs, and achieve high production efficiency, low production costs, and improved cylinder efficiency. The effect of compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

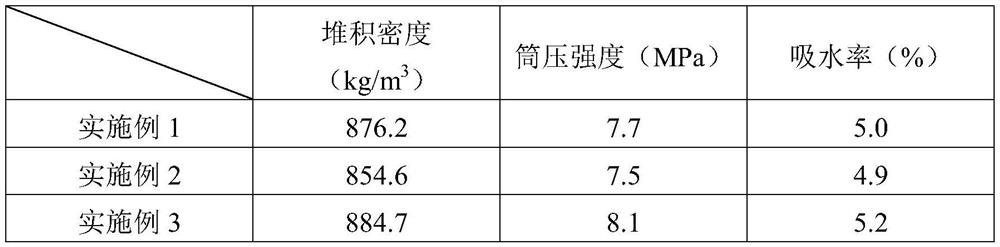

Embodiment 1

[0032] An iron tailings non-burning ceramsite, which consists of the following components in parts by weight: 60 parts of iron tailings, 20 parts of steel slag, 20 parts of fly ash, 10 parts of quicklime, 0.8 parts of dihydrate gypsum, and 0.8 parts of triethanolamine , 3 parts of sodium hydroxide, 3 parts of sodium silicate, 5 parts of sodium bicarbonate.

[0033] The preparation method of the iron tailings unfired ceramsite specifically includes the following steps.

[0034] Step 1. According to the corresponding parts by weight, each component is weighed for subsequent use.

[0035] Step 2. Use the DHG-9075A type electric blast drying oven to dry the iron tailings and steel slag and control the water content within 1%. Use a 5kg laboratory ball mill to dry the iron tailings, steel slag, triethanolamine and dihydrate gypsum The mixture is ground for 150-200 minutes, and the ground iron tailings are passed through a 300-mesh sieve to obtain fine powder.

[0036] Step 3. Mix...

Embodiment 2

[0040] An iron tailings non-burning ceramsite, which consists of the following components in parts by weight: 55 parts of iron tailings, 15 parts of steel slag, 15 parts of fly ash, 10 parts of quicklime, 0.5 parts of dihydrate gypsum, and 0.5 parts of triethanolamine , 2 parts of sodium hydroxide, 2 parts of sodium silicate, and 5 parts of sodium bicarbonate.

[0041] The preparation method of the iron tailings unfired ceramsite specifically includes the following steps.

[0042] Step 1. According to the corresponding parts by weight, each component is weighed for subsequent use.

[0043] Step 2. Use the DHG-9075A type electric blast drying oven to dry the iron tailings and steel slag and control the water content within 1%. Use a 5kg laboratory ball mill to dry the iron tailings, steel slag, triethanolamine and dihydrate gypsum The mixture is ground for 150-200 minutes, and the ground iron tailings are passed through a 300-mesh sieve to obtain fine powder.

[0044] Step 3....

Embodiment 3

[0048] An iron tailings unburned ceramsite, which consists of the following components in parts by weight: 65 parts of iron tailings, 25 parts of steel slag, 25 parts of fly ash, 15 parts of quicklime, 1 part of dihydrate gypsum, and 1 part of triethanolamine , 4 parts of sodium hydroxide, 4 parts of sodium silicate, 10 parts of sodium bicarbonate.

[0049] The preparation method of the iron tailings non-burning ceramsite includes the following steps: Step 1. According to the corresponding parts by weight, each component is weighed for later use.

[0050] Step 2. Use the DHG-9075A type electric blast drying oven to dry the iron tailings and steel slag and control the water content within 1%. Use a 5kg laboratory ball mill to dry the iron tailings, steel slag, triethanolamine and dihydrate gypsum The mixture is ground for 150-200 minutes, and the ground iron tailings are passed through a 300-mesh sieve to obtain fine powder.

[0051] Step 3. Mix all components into a mixer and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com