Method for catalyzing ozone to reinforce sludge dewatering by using sludge-derived biochar

A technology of sludge dehydration and biochar, applied in water/sludge/sewage treatment, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve enhanced sludge dehydration effect, efficient destruction of sludge floc structure, lightening The effect of environmental capacity loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

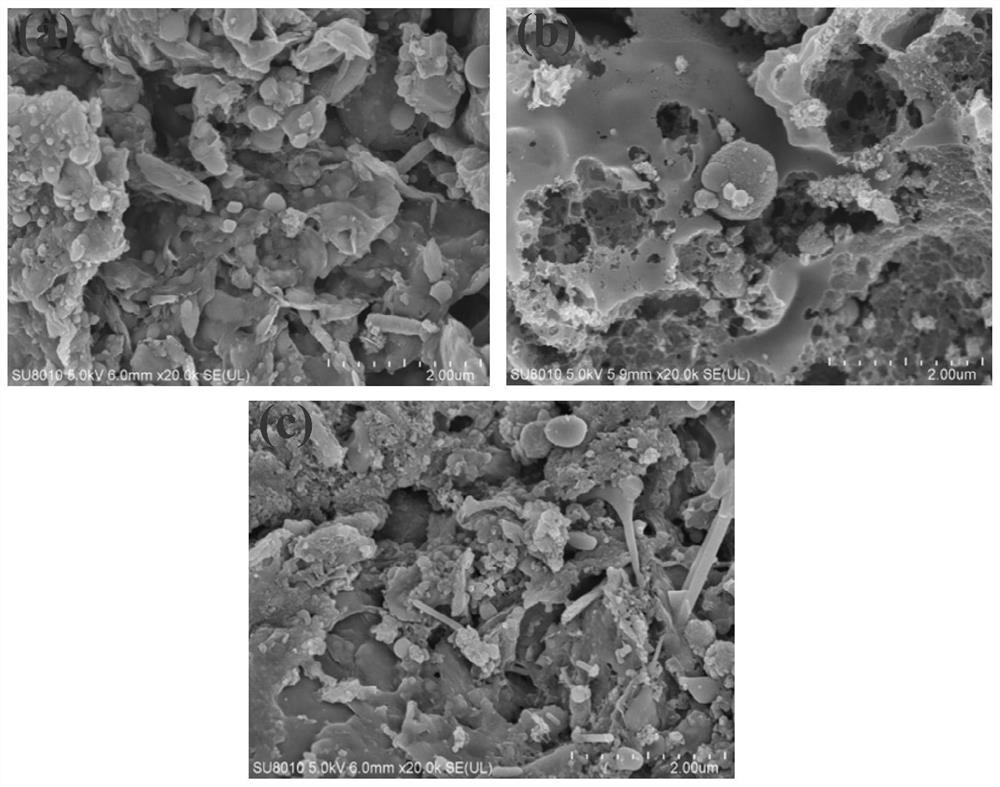

Image

Examples

Embodiment 1

[0030] The present invention provides a method for utilizing sludge-derived biochar to catalyze ozone-enhanced sludge dehydration. The specific implementation process is as follows:

[0031] (1) Preparation of sludge derived biochar:

[0032] The sludge from the sewage plant was dried at 80°C, ground and sieved through a 60-mesh sieve; calcined in a tube furnace at 600°C, with nitrogen as the carrier gas, the gas flow rate was controlled at 100mL / min, and the temperature was 8°C / min. The heating rate of min starts the pyrolysis program from room temperature, the pyrolysis time is controlled at 60 min, and the cooling rate is 10 °C / min down to room temperature to end the pyrolysis process, and the sludge biochar is collected; the Mn(NO 3 ) 2 ·6H 2 O and Fe(NO 3 ) 3 9H 2O Prepare a solution with a molar ratio of manganese and iron of n(Mn):n(Fe)=1:1, add sludge biochar to the solution, and stir for 10 minutes at a stirring speed of 100rpm / min to make the solution evenly mix...

Embodiment 2

[0036] The present invention provides a method for utilizing sludge-derived biochar to catalyze ozone-enhanced sludge dehydration. The specific implementation process is as follows:

[0037] (1) Preparation of sludge derived biochar:

[0038] The sludge from the sewage plant was dried at 90°C, ground and sieved through an 80-mesh sieve; calcined in a tube furnace at 750°C, with nitrogen as the carrier gas, the gas flow rate was controlled at 120mL / min, and the temperature was 10°C / min. The heating rate of min starts the pyrolysis program from room temperature, the pyrolysis time is controlled to 80min, the cooling rate is 15°C / min down to room temperature to end the pyrolysis process, and the sludge biochar is collected; the MnCl 2 4H 2 O and FeCl 3 ·6H 2 O Prepare a solution with a molar ratio of manganese and iron of n(Mn):n(Fe)=1:2, add sludge biochar to the solution, and stir for 15 minutes at a stirring speed of 150 rpm / min to make the solution evenly mixed ;Use ultra...

Embodiment 3

[0042] The present invention provides a method for utilizing sludge-derived biochar to catalyze ozone-enhanced sludge dehydration. The specific implementation process is as follows:

[0043] (1) Preparation of sludge derived biochar:

[0044] The sludge from the sewage plant was dried at 110°C, ground and sieved through a 100-mesh sieve; calcined in a tube furnace at 1080°C, with nitrogen as the carrier gas, the gas flow rate was controlled at 300mL / min, and the temperature was 20°C / min. The heating rate of min starts the pyrolysis program from room temperature, the pyrolysis time is controlled to 260min, the cooling rate is 30°C / min down to room temperature to end the pyrolysis process, and the sludge biochar is collected; KMnO 4 and FeSO 4 ·7H 2 O Prepare a solution with a molar ratio of manganese and iron of n(Mn):n(Fe)=2:5, add sludge biochar to the solution, and stir for 20 minutes at a stirring speed of 150rpm / min to make the solution evenly mixed ;Use ultrasonic powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com