Synchronous edge grinding and trimming device for materials

A technology of edge trimming and edge grinding, which is applied in the direction of grinding drive device, grinding/polishing safety device, machine tool suitable for grinding workpiece edge, etc. Waste easily splashes and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

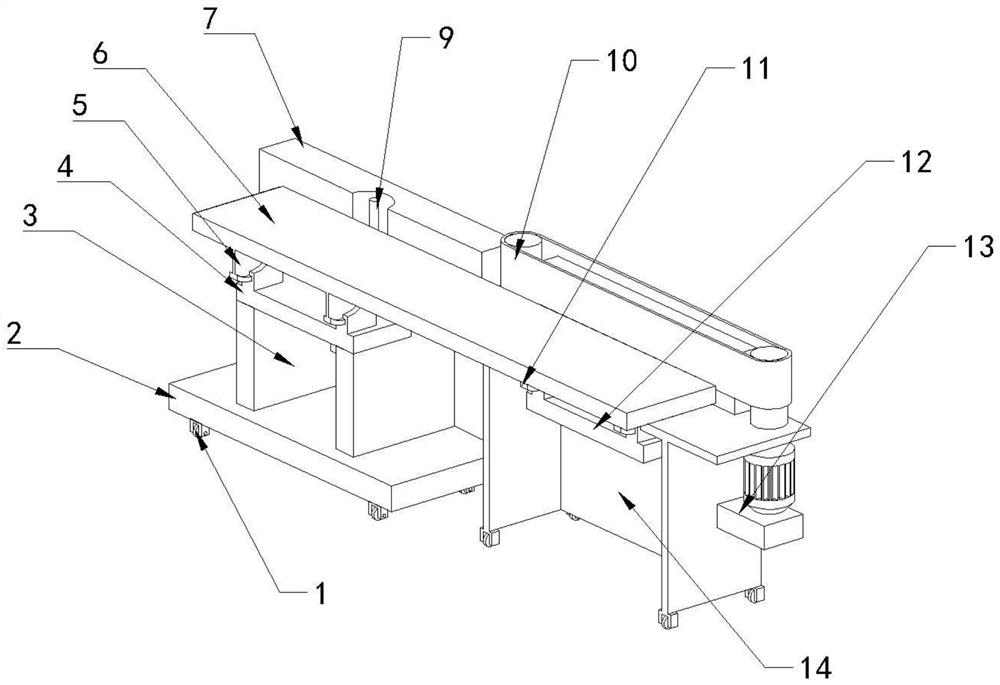

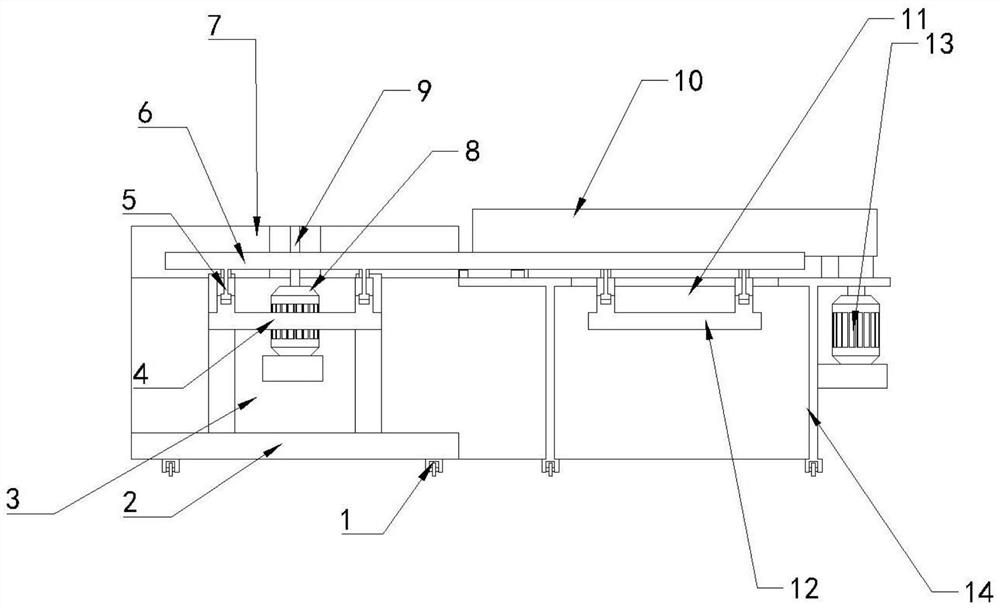

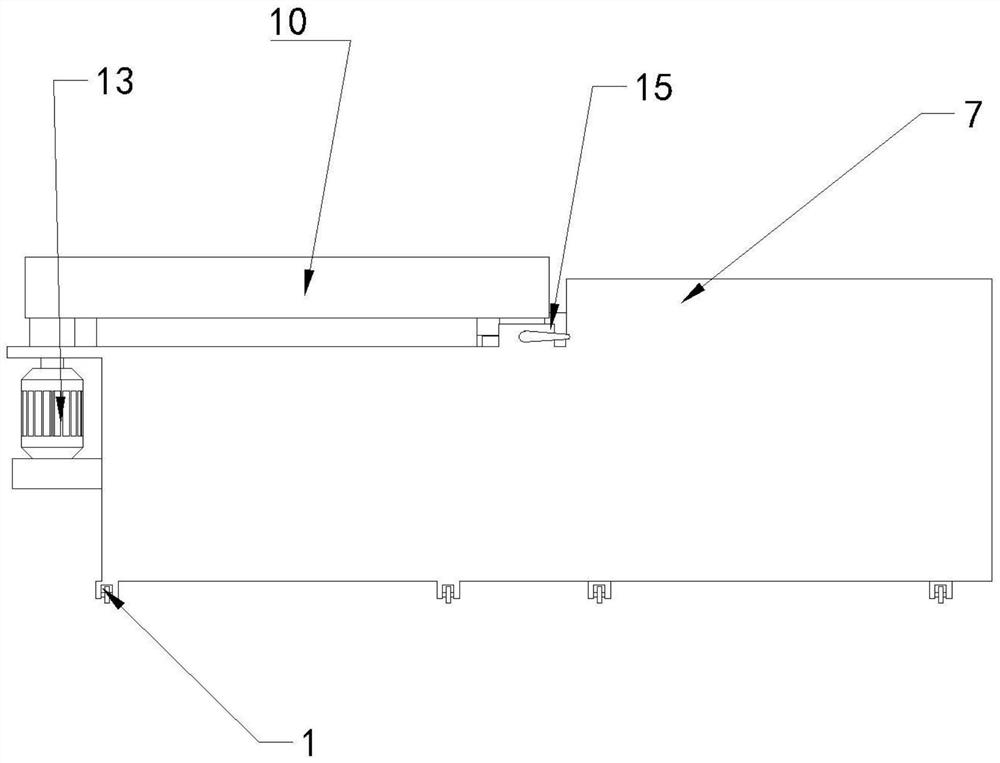

[0024] as attached figure 1 to attach Image 6 Shown:

[0025] A material synchronous edging and trimming device, including a base 2, characterized in that: a pulley 1 is arranged under the base 2 of the main body of the equipment, a waste outlet 3 is arranged above the base 2, and a left side is arranged above the waste outlet 3 A slider base 4, a left slider 5 is connected above the left slider base 4, and a workbench 6 is connected above the left slider 5;

[0026] The rear of the base 2 is connected with a table wall 7, the left slider base 4 in the table wall 7 is provided with a left motor 8, and the left motor 8 is connected with a trimming rod 9;

[0027] A sandpaper transmission belt 10 is arranged on the right side of the workbench 6, and an elastic mechanism 15 is arranged on the left side of the sandpaper transmission belt 10. A right motor 13 is connected to the bottom of the sandpaper transmission belt 10, and a right motor 13 is connected to the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com