Tool rest cooling structure for machine tool

A technology of cooling structure and tool holder, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problem of poor stability of metal hose or plastic Pipe or plastic pipe bending and other problems, to achieve the effect of reducing workload, simple structure and avoiding deformation and dislocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

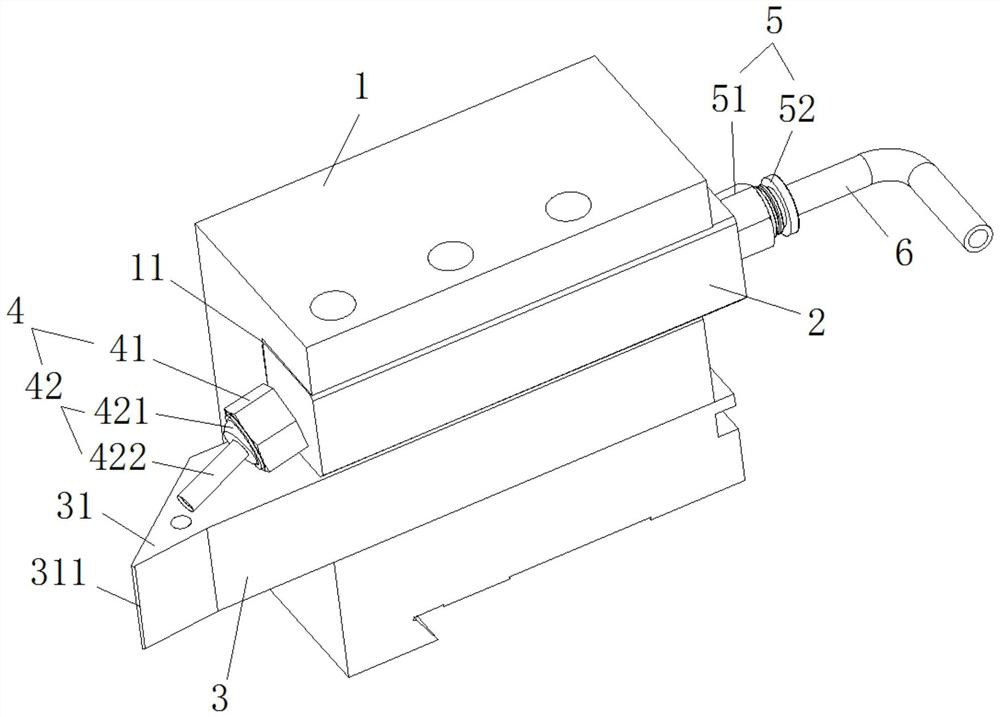

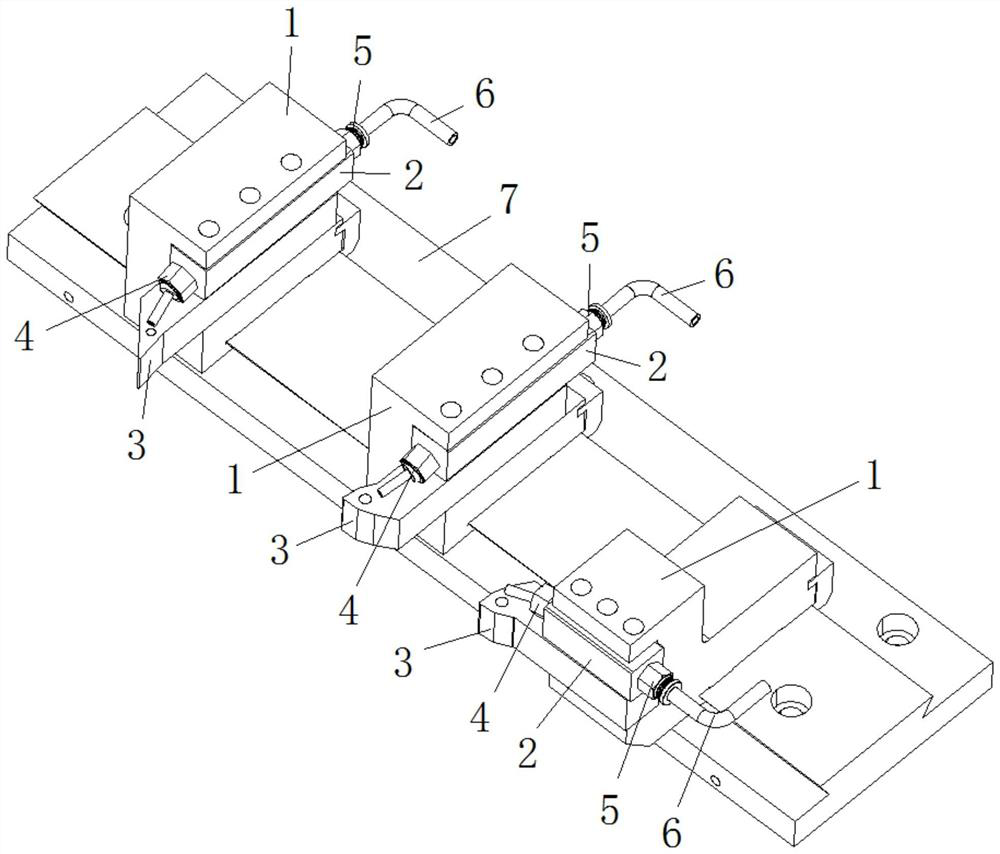

[0021] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the following examples are combined with the appended figure 1 to attach image 3 The technical solutions provided by the present invention are described in detail, but the following content is not intended as a limitation of the present invention.

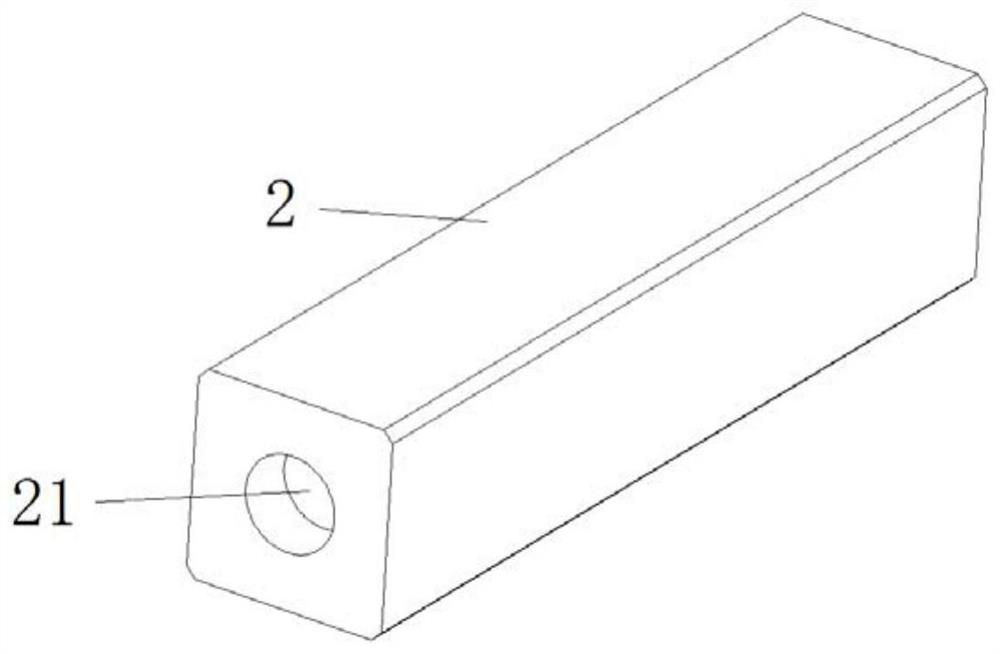

[0022] figure 1 It is a structural diagram of an embodiment of a tool post cooling structure for a machine tool of the present invention; figure 2 It is a structural diagram of a tool press block in a cooling structure of a tool holder for a machine tool according to the present invention. Such as figure 1 and figure 2 As shown, the tool rest cooling structure for machine tools provided by this embodiment includes: a tool seat 1 and a presser block 2. At this time, the tool seat 1 is provided with a tool mounting groove 11, and several connecting tool mounting grooves are provided on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com