Extrusion die and aluminum alloy profile extrusion method

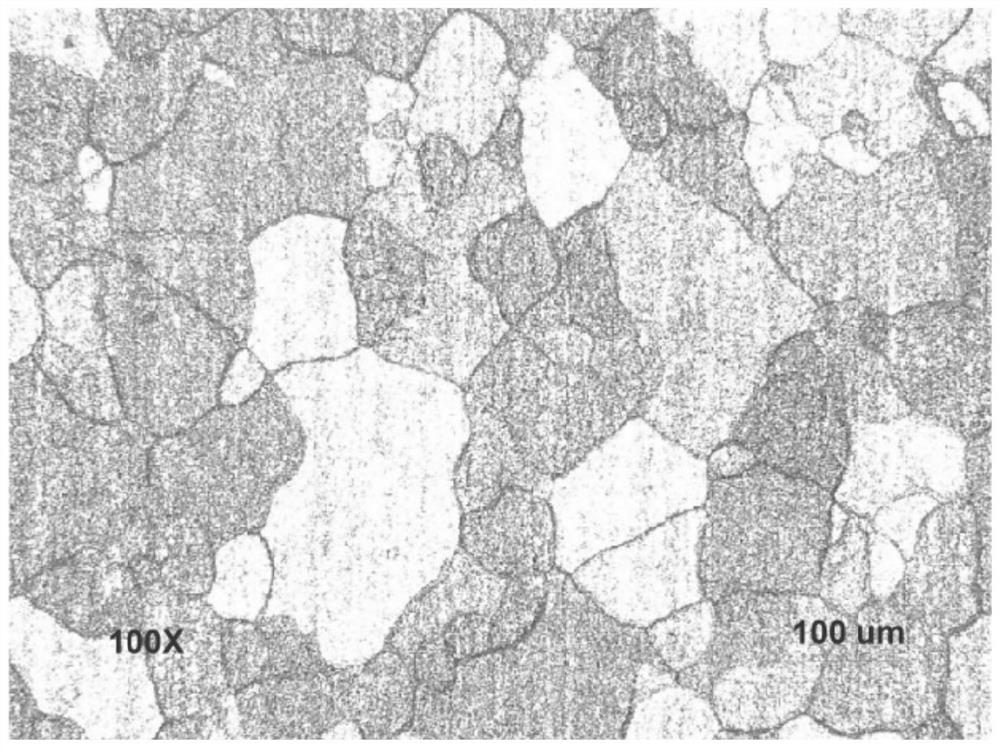

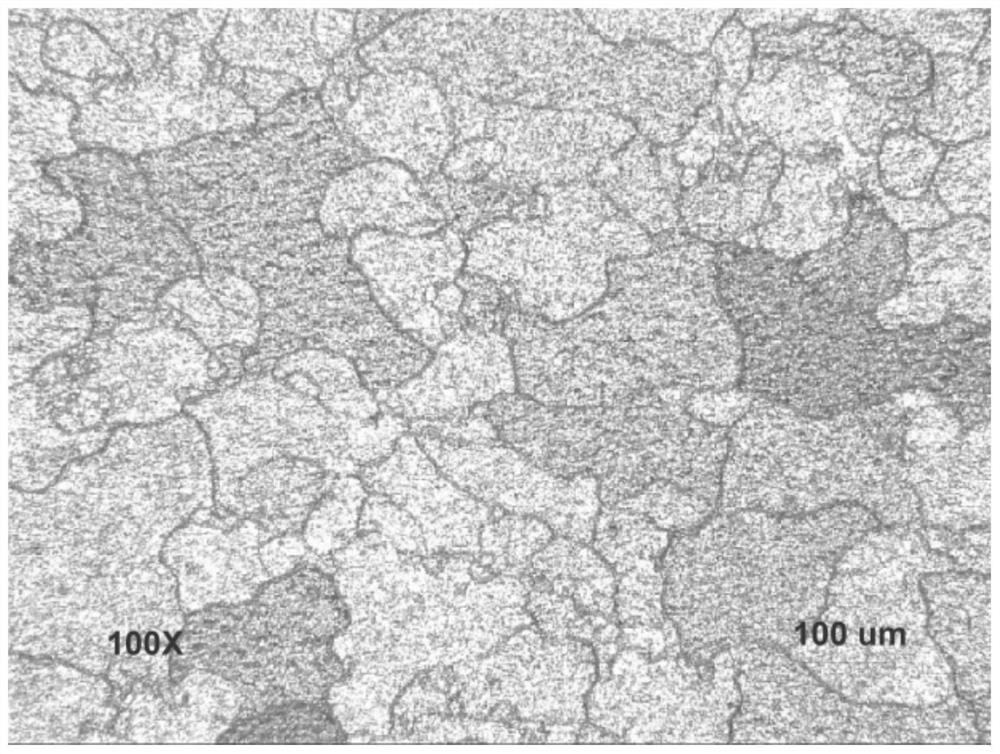

An extrusion die and extrusion method technology are applied in the extrusion field of extrusion dies and aluminum alloy profiles, which can solve the problems of affecting the performance of aluminum alloy profiles, slow advancing speed of raw materials, and coarse recrystallization, etc. The effect of saving raw materials and uniform organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] In this embodiment, a forward extrusion method is adopted to prepare a special-shaped aluminum alloy profile with a rounded rectangular cross section, wherein the extrusion die, method and composition of the aluminum alloy raw material used for preparing the aluminum alloy profile are as follows:

[0077] Preparation of extrusion dies for aluminum alloy profiles

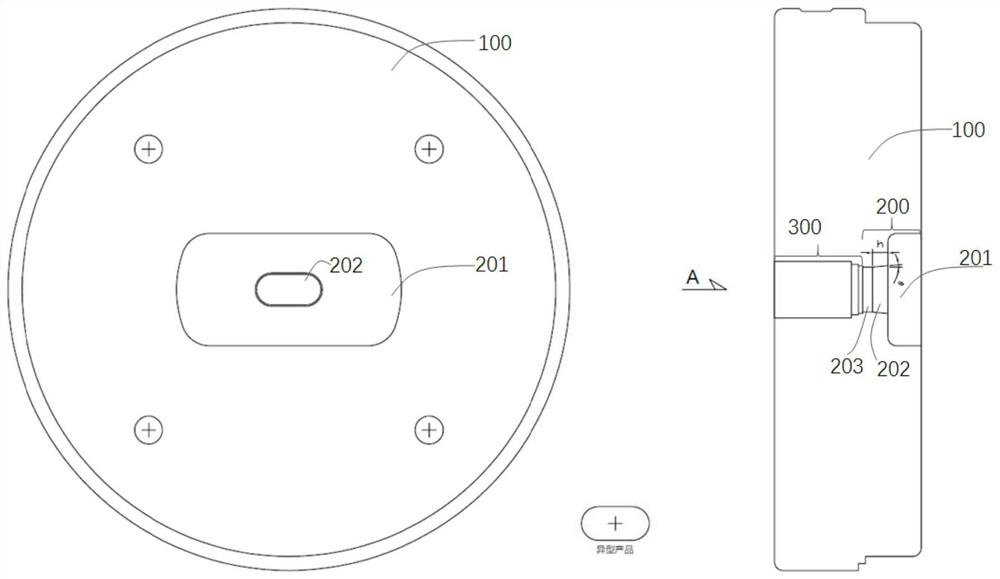

[0078] Extrusion die used in this embodiment, such as figure 1 shown, including

[0079] Ontology;

[0080] Extrusion channel, the extrusion channel is set in the body and runs through the body; the extrusion channel includes diversion grooves, tapered grooves and working belts connected in sequence; the cross-sectional shapes of the diversion grooves, tapered grooves and working belts are the same;

[0081] Diversion groove, the top of the diversion groove is provided with a rounded rectangular opening, the opening size is 140mm×80mm, and the fillet radius is 11.5mm; the bottom is provided with a rounded re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com