Method for cleaning gas chromatographic column for analyzing trace impurities in high-purity carbonic ester

A gas chromatographic column and trace impurity technology, applied in the field of gas chromatographic column cleaning, can solve the problems of long time-consuming, cumbersome process, unsuitable for daily operation, etc., and achieve the effect of short time-consuming, simple operation, and no component residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

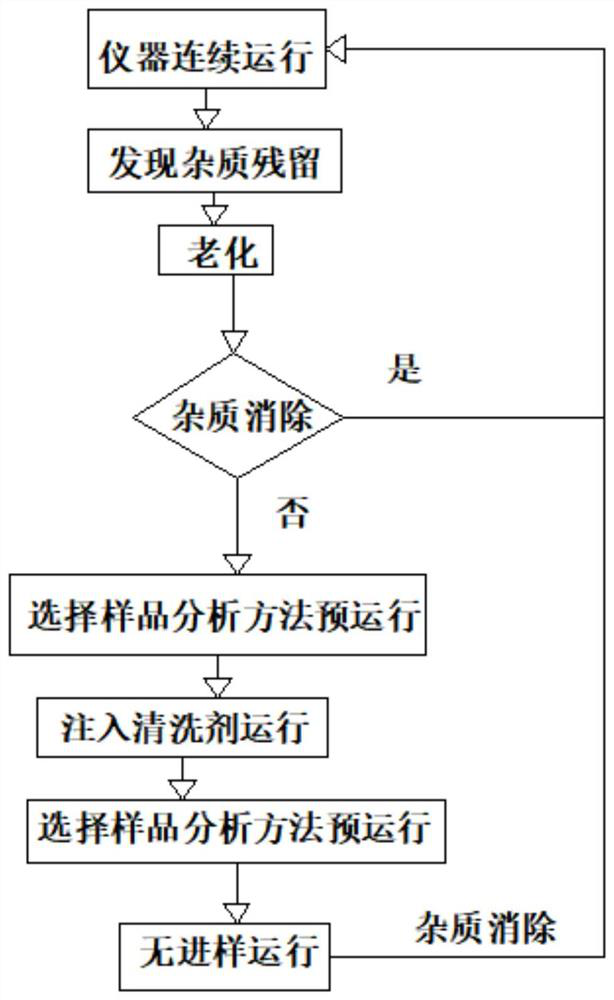

[0025] After the diethyl carbonate sample analysis instrument has been running for a period of time, it is found that there are 1-10ppm impurity peaks remaining after the diethyl carbonate chromatographic peak, and aging at a temperature 20°C lower than the maximum temperature of the chromatographic column has no obvious effect. Perform the following operate:

[0026] Step 1: Select the diethyl carbonate sample analysis method on the chromatograph to pre-run the instrument;

[0027] Step 2: After the instrument is ready, inject an ultra-pure dimethyl carbonate sample (a dimethyl carbonate content above 99.99%) to run;

[0028] Step 3: After the operation is finished, continue to select the diethyl carbonate sample analysis method to make the instrument pre-run;

[0029] Step 4: After the instrument is ready, run without sample injection;

[0030] Step 5: After the operation is over, perform the verification of no-injection operation, and the aging invalid impurities have bee...

Embodiment 2

[0033] After running the propylene carbonate sample analysis instrument for a period of time, it is found that there are 1-10ppm impurity peaks remaining after the propylene carbonate chromatographic peak, and aging at a temperature 20°C lower than the maximum temperature of the chromatographic column has no obvious effect, and the following operations are performed:

[0034] Step 1: Select the propylene carbonate sample analysis method on the chromatograph to make the instrument pre-run;

[0035] Step 2: After the instrument is ready, inject ultra-pure ethanol samples (more than 99.99% ethanol content) to run;

[0036] Step 3: After the operation is finished, continue to select the propylene carbonate sample analysis method to make the instrument pre-run;

[0037] Step 4: After the instrument is ready, run without sample injection;

[0038] Step 5: After the operation is over, perform the verification of no-injection operation, and the aging invalid impurities have been elim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com