Composite tissue adhesive as well as preparation method and application thereof

A composite tissue and adhesive technology, applied in applications, surgical adhesives, bandages, etc., can solve the problems of lack of mechanical strength and low tissue adhesion strength of adhesives, and achieve the effect of accelerating hydration expansion and drying speed. , the effect of high liquid absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

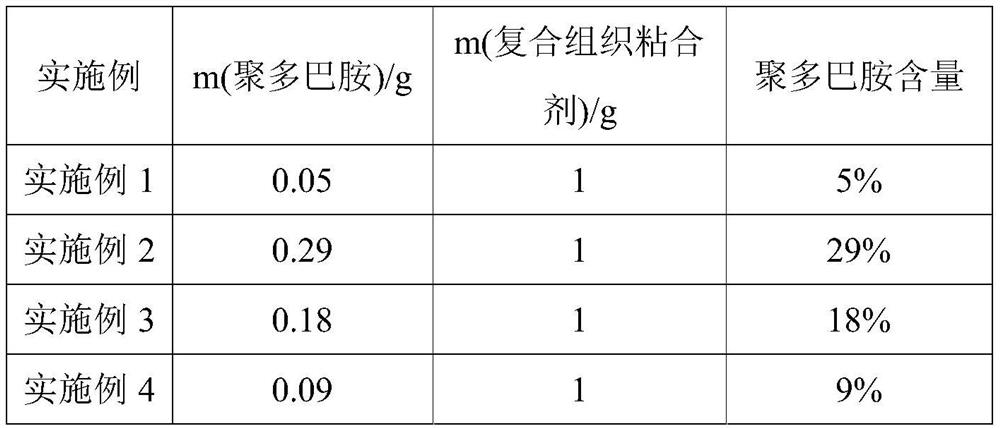

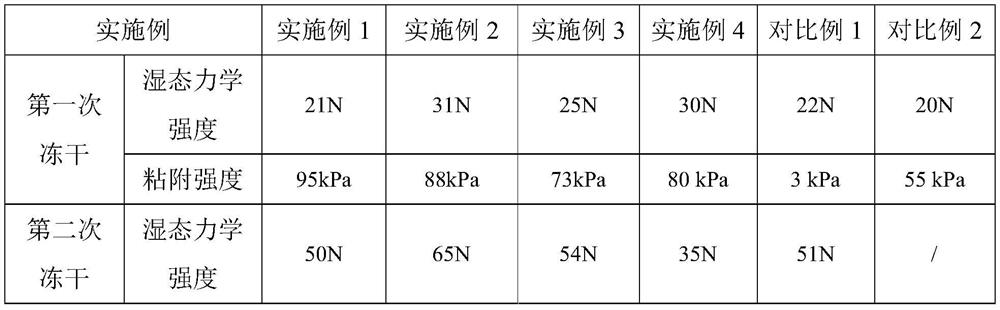

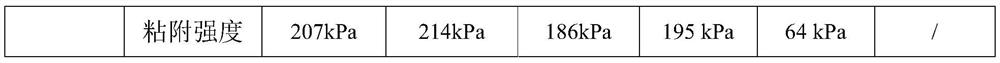

Examples

Embodiment 1

[0042] A composite tissue adhesive, the composite tissue adhesive comprises a three-dimensional porous matrix and an enhanced adhesion factor adsorbed on the surface of the matrix, the three-dimensional porous matrix is composed of methacrylic anhydride gelatin and N-hydroxysuccinimide grafted polyamide. The composite hydrogel of acrylic acid is obtained by freeze-drying, and the adhesion-enhancing factor is polydopamine,

[0043] The composite tissue adhesive also includes polylysine and polyethyleneimine, and the carboxyl groups of polylysine and polyethyleneimine are linked to the succinimide end groups of the polyacrylic acid graft through peptide bonds.

[0044] The preparation method of composite tissue adhesive comprises the following steps:

[0045] S1: Mix methacrylic anhydride gelatin (the substitution rate of methacrylic acid is 75%) and polyacrylic acid, and perform NHS grafting on polyacrylic acid: weigh 20 mL of water into a beaker, add 2 g of polyacrylic acid,...

Embodiment 2

[0051] A composite tissue adhesive, the composite tissue adhesive comprises a three-dimensional porous matrix and an enhanced adhesion factor adsorbed on the surface of the matrix, the three-dimensional porous matrix is composed of methacrylic anhydride gelatin and N-hydroxysuccinimide grafted polyamide. The composite hydrogel of acrylic acid is obtained by freeze-drying, and the adhesion-enhancing factor is polydopamine,

[0052] The composite tissue adhesive also includes polylysine, and the carboxyl group of polylysine is connected to the succinimide end group of the polyacrylic acid graft through a peptide bond.

[0053] The preparation method of composite tissue adhesive comprises the following steps:

[0054] S1: Mix methacrylic anhydride gelatin (the substitution rate of methacrylic acid is 95%) and polyacrylic acid, and perform NHS grafting on polyacrylic acid: Weigh 20 mL of water into a beaker, add 5 g of polyacrylic acid and 2 g of EDC successively , NHS 0.5g, me...

Embodiment 3

[0060] A composite tissue adhesive, the composite tissue adhesive comprises a three-dimensional porous matrix and an enhanced adhesion factor adsorbed on the surface of the matrix, the three-dimensional porous matrix is composed of methacrylic anhydride gelatin and N-hydroxysuccinimide grafted polyamide. The composite hydrogel of acrylic acid is obtained by freeze-drying, and the adhesion-enhancing factor is polydopamine,

[0061] The composite tissue adhesive further comprises polyethyleneimine, and the carboxyl group of polyethyleneimide is connected to the succinimide end group of the polyacrylic acid graft through a peptide bond.

[0062] The preparation method of composite tissue adhesive comprises the following steps:

[0063] S1: Mix methacrylic anhydride gelatin (the substitution rate of methacrylic acid is 85%) and polyacrylic acid, and perform NHS grafting on polyacrylic acid: weigh 20 mL of water into a beaker, add 3 g of polyacrylic acid and 1 g of EDC successive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com