Contactor production line

A contactor and production line technology, applied in relays, electrical components, circuits, etc., can solve the problems of large space occupation, low assembly efficiency, and large number of people.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Below in conjunction with accompanying drawing this embodiment is described in detail:

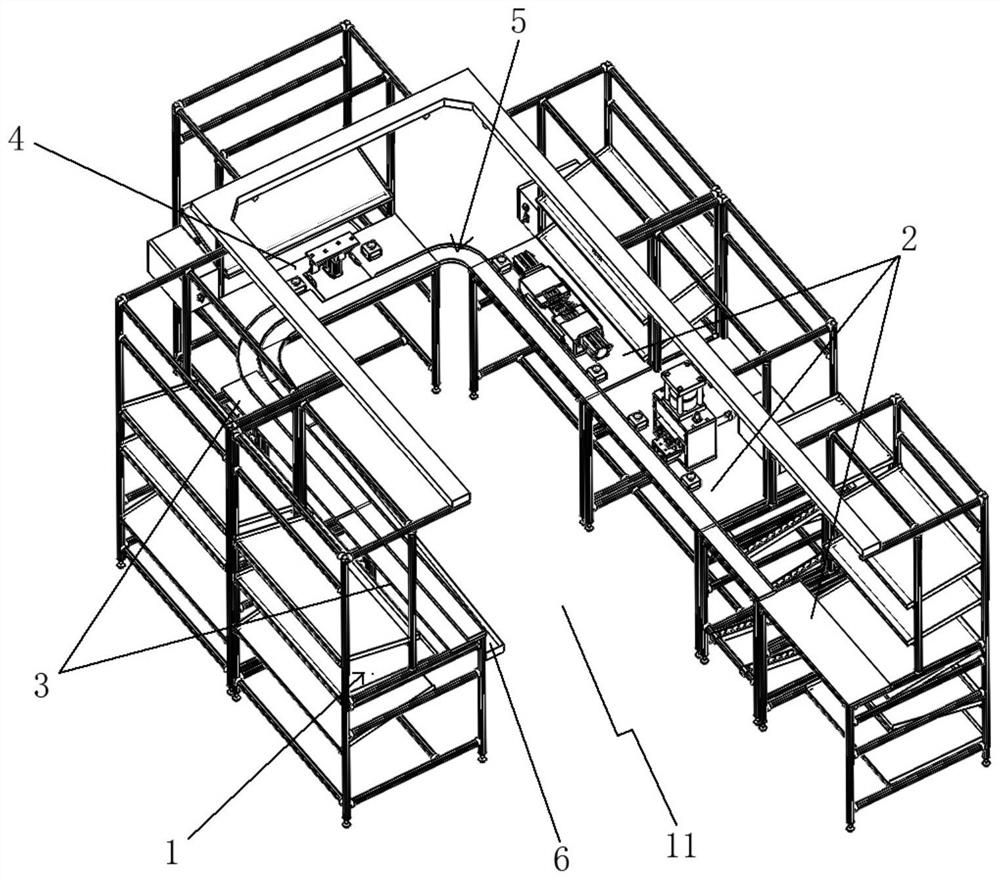

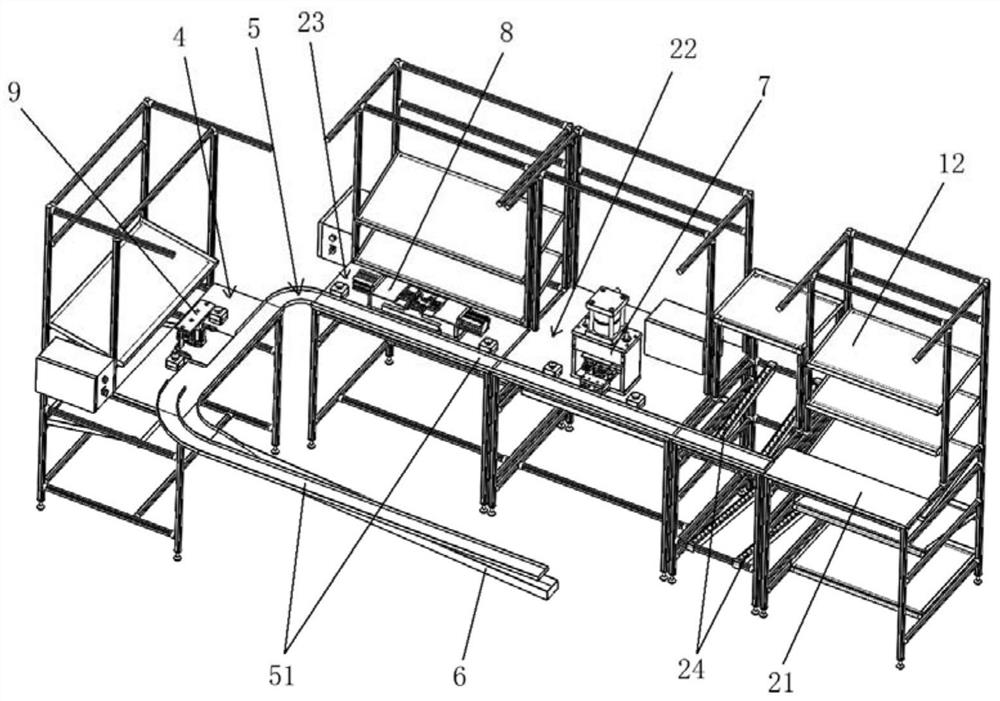

[0058] This embodiment provides as Figure 1-11 A contactor production line is shown, including:

[0059] The feeding assembly platform 1 is arranged in a U-shaped structure, and a U-shaped section 11 is formed on its inner side;

[0060] The base component assembly line 2 is set on one side of the material supply assembly platform 1, which is used to manually and / or automatically assemble the armature assembly, contact components, and arc extinguishing components onto the base, and assemble to form the base semi-finished products;

[0061] Base component assembly line 3, opposite to the base component assembly line 2, is arranged on the other side of the feeding assembly table 1, which is used to manually and / or automatically assemble the yoke assembly and the coil assembly onto the base, and Assemble to form base semi-finished products;

[0062] The intermediate assembly line ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com