High-water-head navigation power generation ship lock

A technology for high water head and ship locks, which is applied in the direction of ship locks, ship lifting devices, engine components, etc. It can solve the problems of high water head ship lock navigation and drainage waste, etc., and achieve the effects of saving navigation time, increasing speed, and reducing waste of water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

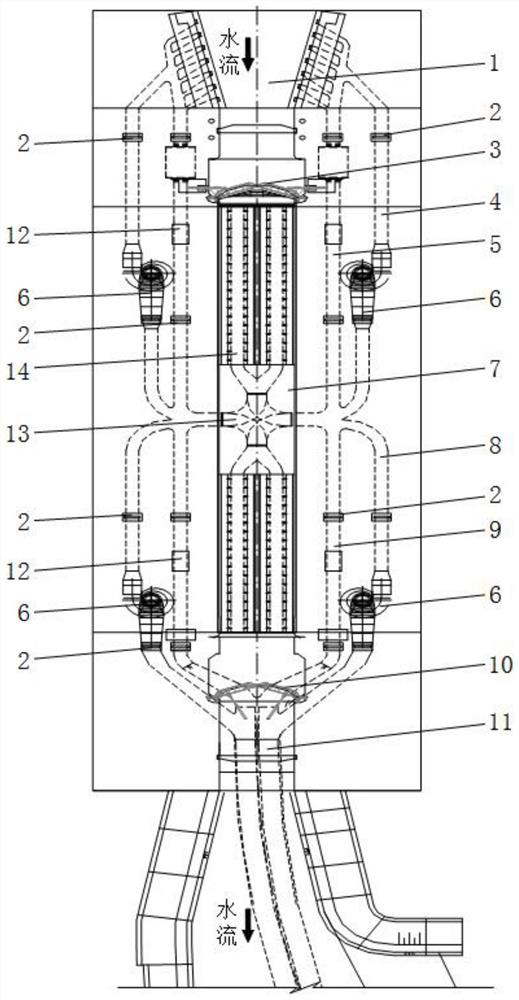

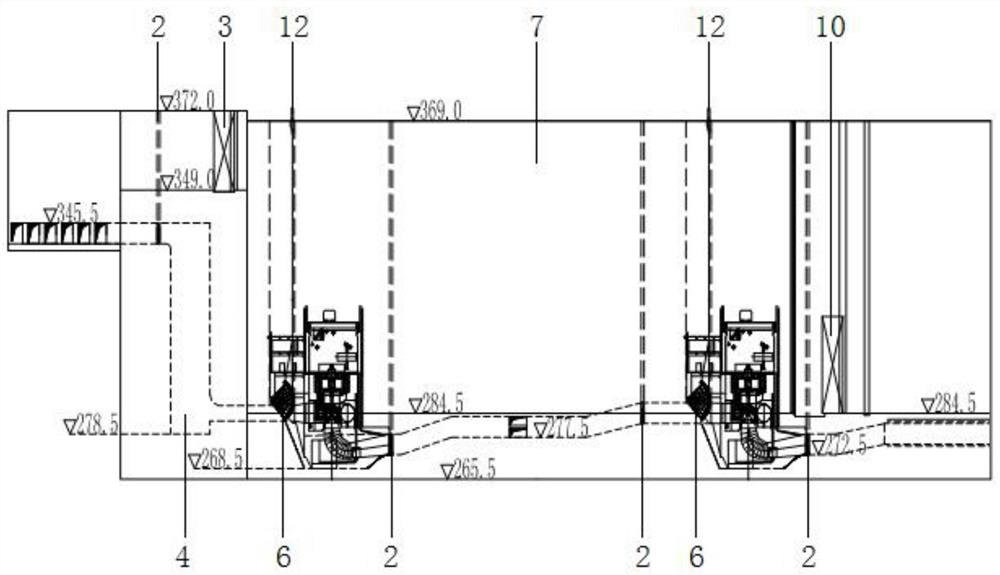

Embodiment 1

[0029] Embodiment 1: Reference figure 1 and figure 2 As shown, the present invention is suitable for the western region where my country's water conservancy resources are relatively abundant, and is generally preferably used for a maximum working water level of not less than 75m, a rated water level of 36m, and a lock length and width of 180m x 23m for navigable 1000-ton ships. The theoretical volume of water in the lock chamber that can be used for power generation is 180×23×70=289,800 m 3 According to the 17 times of ship navigation every day, the time for filling or releasing water in the lock chamber is 30 minutes each time, and the operation of the ship lock is calculated as 330 days a year. Four 41MW hydroelectric generators are selected, and the annual power generation is theoretically about 200 million degrees. ; When the sluice chamber is filled with water or discharged to generate electricity, the hydro-generator unit starts to start, and it takes about one minute t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com