HDPE winding pipe production equipment

A technology for producing equipment and winding pipes, applied in the field of HDPE winding pipe production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

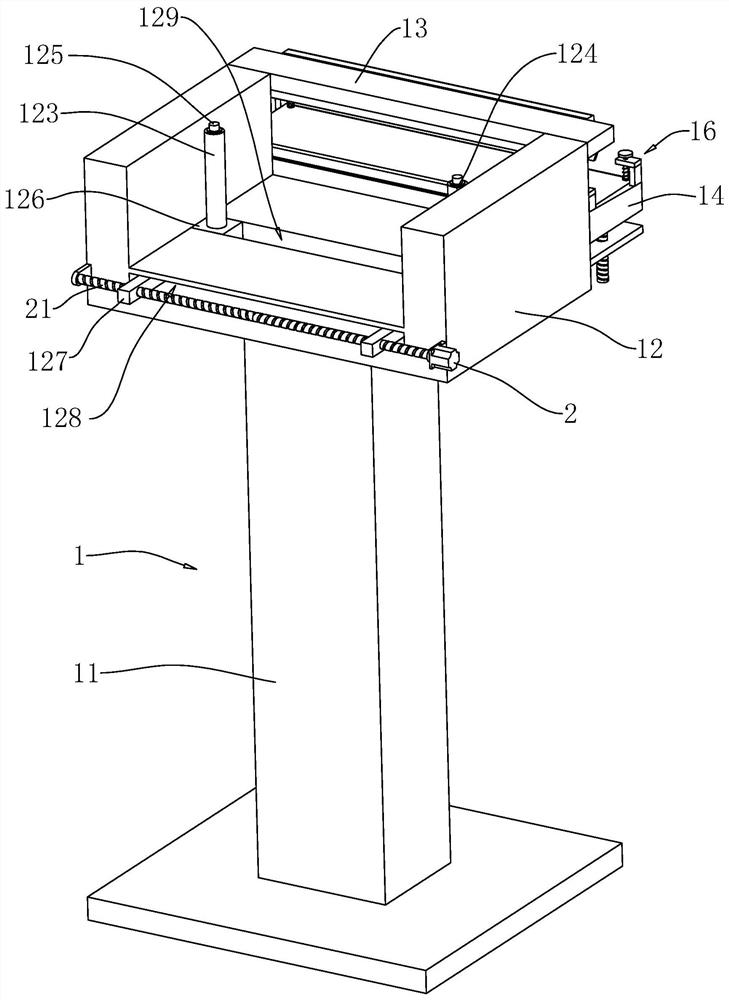

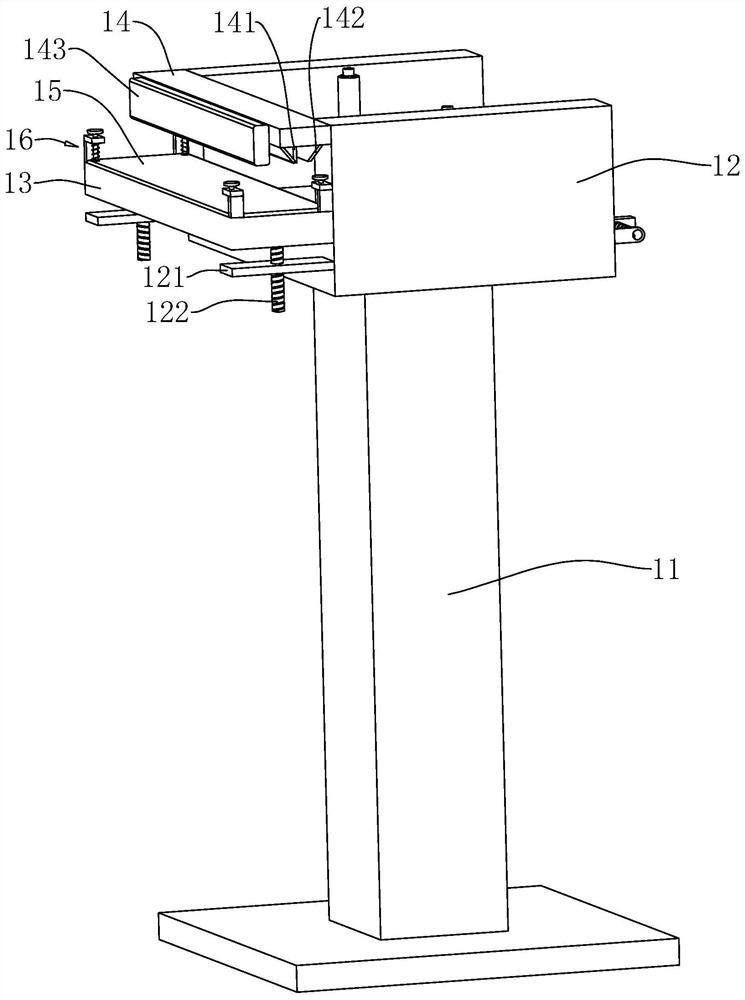

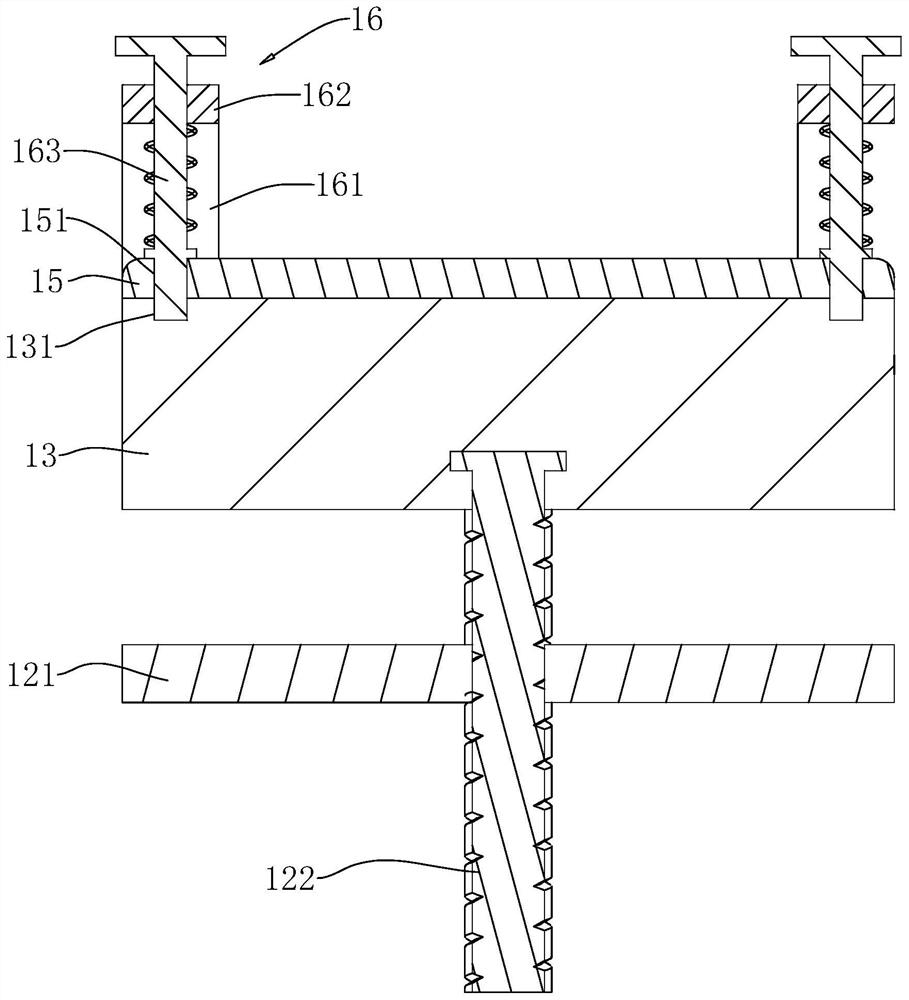

[0030] The following is attached Figure 1-3 The application is described in further detail.

[0031] It is a kind of HDPE winding pipe production equipment disclosed in the embodiment of this application. refer to figure 1 , HDPE winding pipe production equipment, including a supporting mechanism 1 for supporting the strip, and the supporting mechanism 1 is arranged between the extruder and the winding forming machine. During processing, the high-density polyethylene (HDPE) is extruded by an extruder into a strip, and the strip passes through the support mechanism 1 after being cooled by water. The support mechanism 1 includes a dehydration component of the support frame 11. There is a placement frame 12, the placement frame 12 is a 匚 shape with the opening facing upwards, and the dehydration component is connected with the placement frame 12. When the strip passes through the placement frame 12, it is dehydrated through the dehydration component, and then processed into HD...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com