Control mechanism for rice crust size and thickness in rice crust production

A technology of thickness control and control mechanism, which is applied in the fields of application, metal processing, food forming, etc., and can solve problems such as not being able to meet the needs of crispy rice, single size, and the influence of the scope of application of the device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

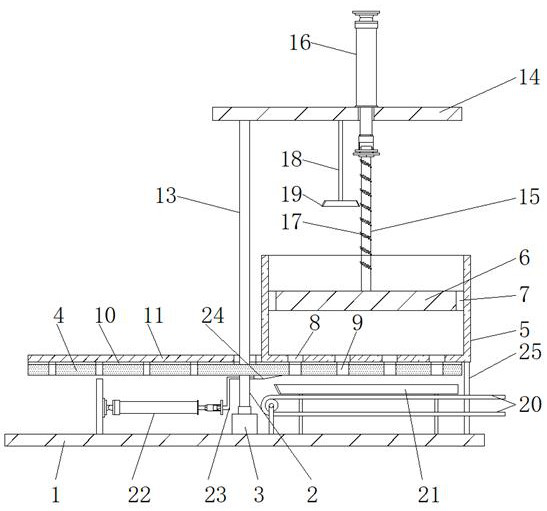

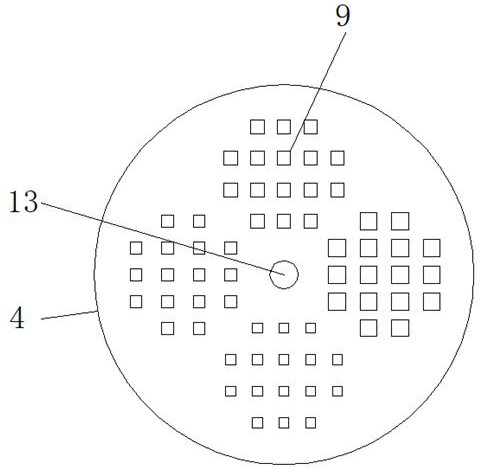

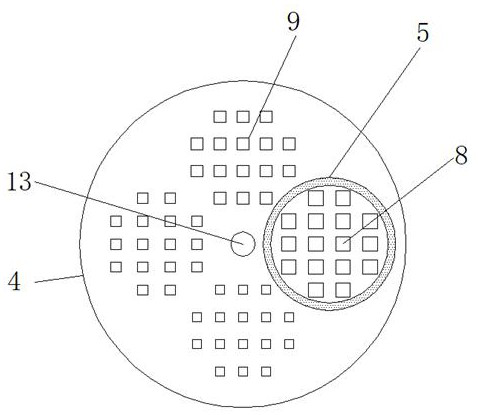

[0029] Such as figure 1 The control mechanism for controlling the size and thickness of crispy rice for rice crispy production as shown includes a base 1, a support plate 4 is arranged horizontally above the base 1, and the top of the base 1 is connected to a support column 25 with a bottom end surface attached to the support. The barrel body 5 on the plate 4, the top of the support plate 4 is connected with a top plate 14 by a fixed column 13, and the top plate 14 is provided with a lifting mechanism that presses down the material inside the barrel body 5, and the bottom ends of the barrel body 5 are equally spaced. There is a discharge port 8, and the top plate 14 is divided into four areas. Each area is provided with a forming material port 9 corresponding to the discharge port 8 and having a size smaller than the size of the discharge port 8. The four areas are formed. The size of the material opening 9 is different, and the size of the forming material opening 9 on each a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com